Some cars are simply built better than others due to smart engineering, high-quality parts, and excellent manufacturing consistency. Reliability secrets mostly come down to a brand prioritizing durability over flashy gadgets and adhering to strict quality control when putting the vehicle together.

Ever wonder why your neighbor’s older car still runs perfectly while yours needs constant visits to the shop? It’s a common headache for drivers everywhere. We all want a car that starts every morning without a fuss. You don’t need to be a seasoned mechanic to understand what makes a car tough. This guide cuts through the confusion. We will reveal the real reasons behind lasting reliability. Get ready to learn what separates the reliable rides from the problem children, making your next car choice much easier.

The Core Truth: Why Reliability Isn’t Random

Car reliability isn’t luck; it’s design. When top brands build great cars, they follow specific blueprints. Think of it like baking a cake: if you use low-quality ingredients or skip crucial steps, the cake falls apart. The same goes for vehicles. We are going to look closely at the secrets that make certain cars famous for going the distance. These factors are often hidden from casual buyers but are clear to engineers.

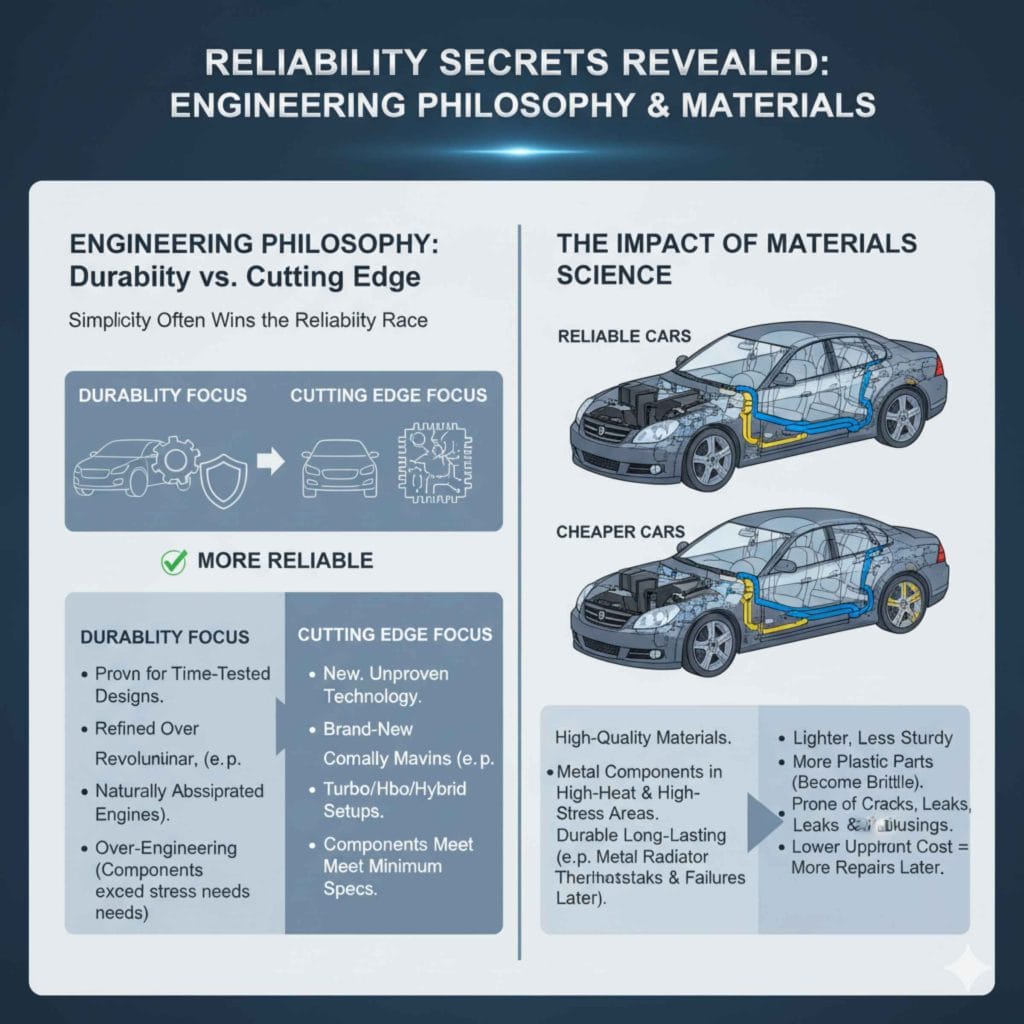

Secret 1: Engineering Philosophy – Durability vs. Cutting Edge

The biggest secret often lies in how the manufacturer approaches the design process. Do they focus on saving a few dollars today, or do they aim for a vehicle that lasts 200,000 miles?

Simplicity Often Wins the Reliability Race

New technology sounds exciting, but new technology usually means new, unproven ways for things to break. Reliable brands often stick with proven, time-tested designs.

- Refined Over Revolutionary: A manufacturer re-releasing an engine they’ve already built and perfected for five years is usually more reliable than one debuting a brand-new, complex engine design that year.

- Fewer Moving Parts: Every part added to a vehicle is a potential point of failure. Simple systems, like naturally aspirated engines versus complex turbo/hybrid setups, have fewer things that can go wrong.

- Over-Engineering: Many highly reliable brands slightly over-engineer components. This means they use bolts, brackets, or engine internals that are rated for much more stress than they will ever see in normal driving.

The Impact of Materials Science

What your car is made of matters just as much as how it’s put together. The cheaper the car appears, the more likely they were to use lighter, less sturdy materials to save costs.

For instance, cheaper cooling systems might use more plastic parts that become brittle with age and heat. More reliable cars invest in metal components for high-heat and high-stress areas, even if those parts cost the company more upfront. You pay for that quality later when you don’t have leaks.

Secret 2: The Parts Bin Gamble – Sourcing Components

A car isn’t built from scratch by one company. It relies on hundreds of suppliers for everything from brake pads to complicated electronic sensors. This is where major reliability gaps appear.

In-House vs. Outsourced Quality

Top reliable brands often prefer to build critical components, like transmissions and engines, themselves. This allows them total control over the design, testing, and quality checks.

When a manufacturer buys a component (like an automatic transmission) from a third-party supplier, they are trusting that supplier’s quality control. If that supplier gets sloppy to meet another client’s cost demands, your car pays the price.

Here is a quick look at component sourcing impact:

| Component Area | High Reliability Approach (In-House/Proven) | Lower Reliability Issue (Outsourced/New) |

|---|---|---|

| Engine Internals | Forged or high-grade cast components; long testing cycles. | Lighter, cheaper materials to improve initial MPG figures. |

| Transmissions | Robust planetary gear sets; proven shifting logic. | Complex dual-clutch systems using unproven software controls. |

| Electronics/Infotainment | Simple, integrated modules that communicate directly. | Complex, third-party infotainment screens prone to freezing or failure. |

Vendor Consistency is Key

Even if a brand uses external suppliers, the most reliable ones maintain extremely strict standards. They audit their suppliers often. If a supplier fails an audit, they are fired, no matter how cheap their parts are. Less reliable manufacturers might overlook quality drops if the parts are cheap enough to keep the sticker price low.

Secret 3: The Assembly Line — Manufacturing Precision

You can have the best parts and the best design, but if they are put together poorly, the car will rattle, leak, and fail prematurely. This is about the factory floor and the people building your vehicle.

Tolerance Stacking: The Hidden Enemy

Mechanics talk about “tolerances”—the tiny allowable gap between two parts fitting together. In a perfectly engineered component, the gap might be 5 millimeters. If the part making the hole is slightly too big (say, 5.1 mm) and the part going into it is slightly too small (say, 4.9 mm), they fit okay but create extra space. This is called tolerance stacking.

Highly reliable brands run incredibly tight quality checks on machinery to minimize these tiny variances. When tolerances stack up across thousands of parts, you get loose trim, oil leaks, or premature wear on belts and bearings. Precision assembly is a massive, often invisible, difference maker.

Robots vs. Human Hands

While modern assembly lines use many robots, the way they are programmed matters. High-reliability factories spend fortunes programming robots to apply the exact right amount of torque (tightness) to every single bolt. Too loose, and it falls out; too tight, and you stretch or break the bolt.

For critical structural components, automation must be flawless. If a factory rushes production or cuts corners on robot calibration to push out more volume, consistency drops immediately. You can often trace reliability issues back to a specific model year where a company rapidly scaled up production volume.

Secret 4: Testing, Testing, and More Testing (The Costly Step)

The most reliable cars spend years enduring intense, real-world testing before they ever reach a dealership lot. This testing phase is expensive, and often, manufacturers try to shorten it to get models to market faster.

Simulated Extreme Conditions

Reliable manufacturers don’t just drive prototypes on sunny highways. They utilize specialized testing facilities that mimic the worst conditions globally:

- Desert Heat Testing: Running vehicles at maximum load in 120°F heat to check cooling systems and rubber component longevity.

- Arctic Cold Testing: Freezing vehicles solid to test battery performance, fluid flow, and how plastics react to extreme cold (see resources on automotive testing standards from the SAE International Technical Standards).

- Salt and Humidity Chambers: Accelerating corrosion by spraying salt water on the undercarriage constantly to check for rust vulnerability.

Real-World Fleet Testing

Before a car launches, reliable companies often run “fleet vehicles” disguised as everyday cars. These vehicles are handed to rental companies, taxi services, or internal employees to drive hundreds of thousands of miles in uncontrolled environments. They are looking for the small things—a squeak, a strange vibration—that only show up after genuine, extended use. Cutting this phase means issues appear on your driveway instead of theirs.

Secret 5: The Fluid of Life – Oil and Cooling Systems

Even the best engine will fail if it overheats or doesn’t get proper lubrication. System reliability often hinges on how well the car manages heat and friction.

Cooling System Robustness

Some cars use smaller radiators or less durable water pumps to save space and weight (again, for initial performance or aesthetics). Reliable cars tend to “over-cool” their engines. They use larger radiators and robust pumps capable of handling extreme stress without overheating or leaking prematurely.

Plastic coolant overflow tanks are notorious failure points as they age. Brands prioritizing long-term wear sometimes opt for metal tanks or use superior, thicker plastics for these components.

Oil Flow Precision

Modern engines rely heavily on perfect oil pressure to keep moving parts lubricated and to manage systems like variable valve timing. More reliable designs often feature simpler lubrication paths ensuring that even if an oil filter degrades slightly, crucial components still receive enough pressure. Less reliable designs might use tiny passages that clog easily, leading to immediate wear.

Secret 6: Maintenance Accessibility and Owner Behavior

While this isn’t strictly about build quality, it’s a key part of why some cars seem more reliable. If maintenance is hard or expensive, owners skip it, leading to failure.

The Cost of an Oil Change

If an oil change takes three hours because the mechanic has to remove the transmission mount and drain plug just to access the oil filter, the average driver might put it off. When maintenance is easy and cheap, people do it on time, keeping the car healthy.

Highly reliable platforms are often designed with the home mechanic or quick-lube shop in mind. Key fluid checks and filter changes are straightforward. If the manufacturer makes routine service difficult, it contributes to lower long-term reliability statistics simply because owners delay essential upkeep.

Service Intervals and Fluid Quality

Some manufacturers recommend extremely long service intervals (e.g., 10,000 miles between oil changes). While this looks good on paper for marketing purposes, it puts more stress on the oil and engine components. Reliable brands often balance long intervals with recommending synthetic oils designed specifically to handle that harsh stress test.

If a vehicle requires a very specific, rare, and expensive fluid to maintain its warranty, owners are more likely to use a cheaper alternative when out of warranty, triggering problems.

Decoding Reliability Ratings: What the Experts Look For

When third-party reviewers like Consumer Reports or J.D. Power compile reliability studies, they are looking at the combined effect of all the secrets we just discussed. They track specific failure rates across different vehicle systems.

Here is a generalized look at what gets weighted heavily in reliability scoring:

| System | High Failure Rate Indicator | Reliability Impact (Beginner View) |

|---|---|---|

| Engine/Powertrain | Overheating, rough idle, sudden power loss. | The heart of the car needs consistent care; failure here means big bills. |

| Transmission | Hard shifting, slipping gears, grinding noises. | The most complex and expensive part to fix properly. |

| Electrical (Non-Infotainment) | Lights failing, dash warning indicators flickering randomly. | Indicates poor wiring protection or cheap sensor quality. |

| Body Integrity | Door seals failing, excessive wind noise, rust development. | Shows poor material choice or weak sealing during assembly. |

When you see a brand consistently score high, it means they are successfully managing the risk across all these diverse areas. They haven’t just made a good engine; they’ve made a good environment for that engine to live in.

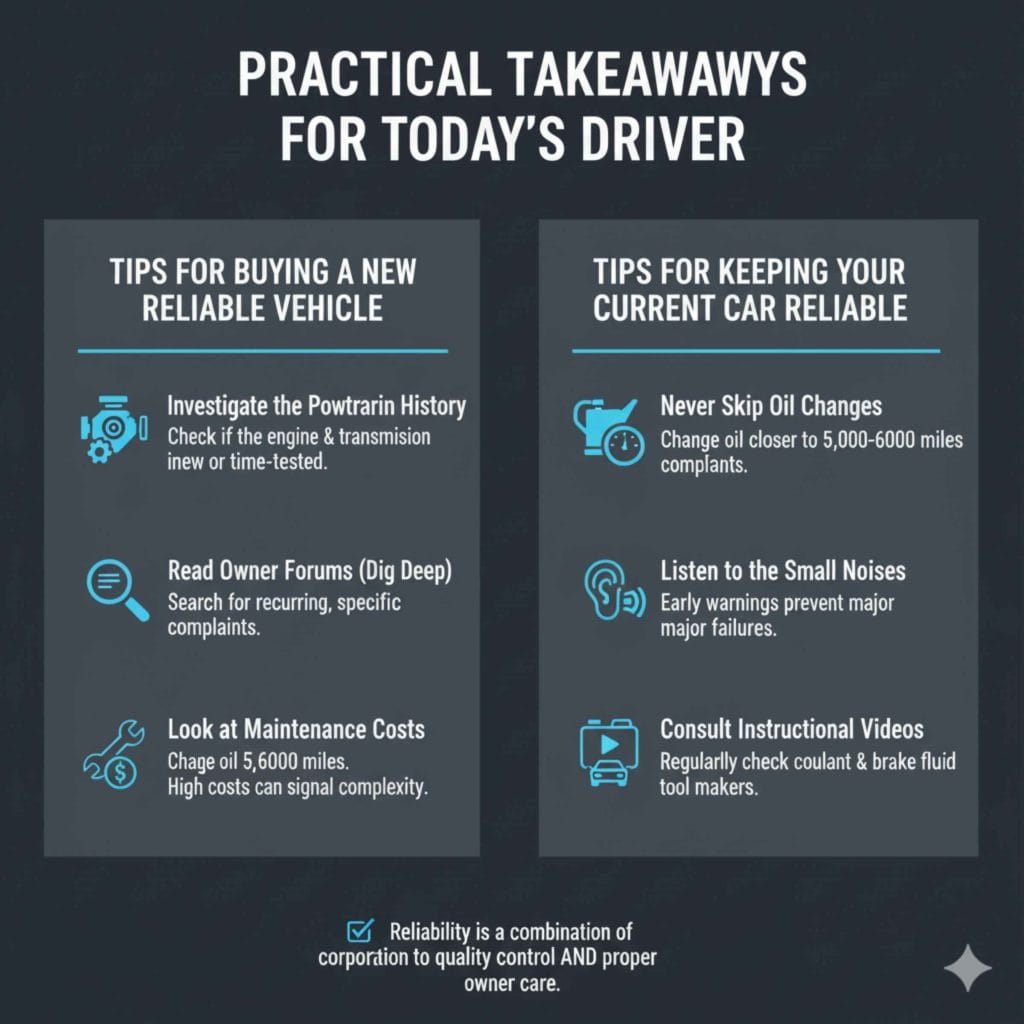

Practical Takeaways for Today’s Driver

Understanding these secrets allows you to be a smarter consumer, whether you are buying new or used. Here are simple steps you can take right now to ensure your current or next car lasts longer.

Tips for Buying a New Reliable Vehicle

- Investigate the Powertrain History: Before buying, look up the specific engine and transmission combo of that model year. Has this combination been around for a while, or is it all-new? New versions often have teething problems.

- Read Owner Forums (Dig Deep): Don’t just read the glowing reviews. Search forums for recurring, specific complaints—like “2021 model transmission shudder” or “water pump leak issue.” A few isolated complaints are okay; a pattern is a red flag.

- Look at Maintenance Costs: Check official ratings on the cost of routine service. If routine service costs a fortune, you are paying the price for complexity or access difficulty.

Tips for Keeping Your Current Car Reliable

No matter what you drive, these habits prevent the small issues from becoming catastrophes, mimicking what the reliable brands build into their systems.

- Never Skip Oil Changes: This is the single most important thing. If the manual says 7,500 miles, consider doing yours closer to 5,000 or 6,000 miles, especially if you drive in stop-and-go traffic.

- Listen to the Small Noises: That slight squeak when you press the brakes or a slight hesitation when accelerating? Don’t ignore it until it stops working entirely. Small noises are early warnings against component wear. You can find great instructional videos on diagnosing minor noises on sites run by reputable tool makers, like those found by searching for maintenance guides from major auto parts suppliers.

- Mind the Fluids: Regularly check the coolant level (when the engine is cold!) and brake fluid level. Low levels are usually the first sign of a small, correctable leak before it becomes a huge repair.

Remember, reliability is a combination of corporate dedication to quality control and proper owner care. By respecting the engineering principles that lead to durability, you drastically improve your experience on the road.

Frequently Asked Questions (FAQ) for Beginner Drivers

Q1: Is a more expensive car always more reliable?

Not always. Sometimes you pay a premium for luxury features or brand prestige. However, premium brands often use higher-grade materials for the core components (engine, suspension), which can lead to longer life, even if things like the navigation screen are complicated.

Q2: Do electric cars (EVs) have better reliability than gas cars?

Generally, yes, they have fewer moving parts in the primary powertrain, meaning no oil changes, spark plugs, or complex transmissions. However, battery degradation and expensive electronic repairs offset this simplicity. They trade mechanical failure risk for electronic failure risk.

Q3: How much does the country of origin matter for reliability?

It matters less now than it did 20 years ago, but general patterns exist. Brands from certain countries have historically prioritized engineering robustness, while others focused more on low manufacturing cost. Look at specific brand reputation, not just the country tag.

Q4: What’s the single easiest thing I can do to make my car last longer?

Change your oil on time, every time, using the correct grade of oil specified in your owner’s manual. Oil leakage is rarely the issue; it’s degraded, old oil failing to lubricate critical moving parts that causes the first wave of engine damage.

Q5: Should I be worried if my two-year-old car has a few electrical glitches—like the radio rebooting?

A few minor electronic glitches, especially involving infotainment screens, are common today. While annoying, these don’t usually affect the driving safety or longevity of the mechanical parts. Fix them under warranty, but don’t panic that the engine is about to fail.

Q6: If a car has a complex turbocharged engine, is it automatically unreliable?

Not necessarily, but complexity adds risk. Turbochargers add heat and pressure, stressing seals and components. If the manufacturer heavily tested and engineered the cooling system and lubrication for that turbo, it can be very reliable. If it’s a new turbo design on a budget platform, be cautious.

Conclusion: Confidence Through Knowledge

Understanding why are some cars more reliable than others shifts the power back to you, the driver. It’s clear that reliability isn’t a myth or a secret reserved for the ultra-wealthy. It’s the traceable result of smart engineering choices, a willingness to spend more on quality components, and rigorous factory testing.

When shopping, use this knowledge to inspect the history of the powertrain and the simplicity of the design. When driving, remember that your commitment to timely, quality maintenance completes the chain. By respecting the physics of materials and proper lubrication, you are ensuring your vehicle benefits from the best potential reliability designed into it. You now have the tools to choose wisely and maintain confidently, ensuring fewer trips to the repair shop and more joyful, worry-free miles ahead.