A tire comes off a car primarily due to severely loose lug nuts caused by improper installation or failure to tighten them after service. Other causes include severe impact damage or extreme rust compromising the wheel assembly. Addressing this requires understanding lug nut torque and regular inspection.

Hello there! I’m Dustin Hall, and if you’ve ever heard a terrifying clunk followed by a sudden, hard pull while driving, you know the panic that hits when you realize a wheel might be separating from your car. It’s a genuinely scary thought, but it’s rare—and almost always preventable. Many drivers worry about this frightening scenario. They think it’s random bad luck. It’s not! Most wheel separations happen because of a few key, fixable mistakes in maintenance. We are going to walk through exactly why this happens, how to spot the warning signs early, and what you can do today to keep your wheels securely attached. Let’s turn this scare into a smart maintenance habit.

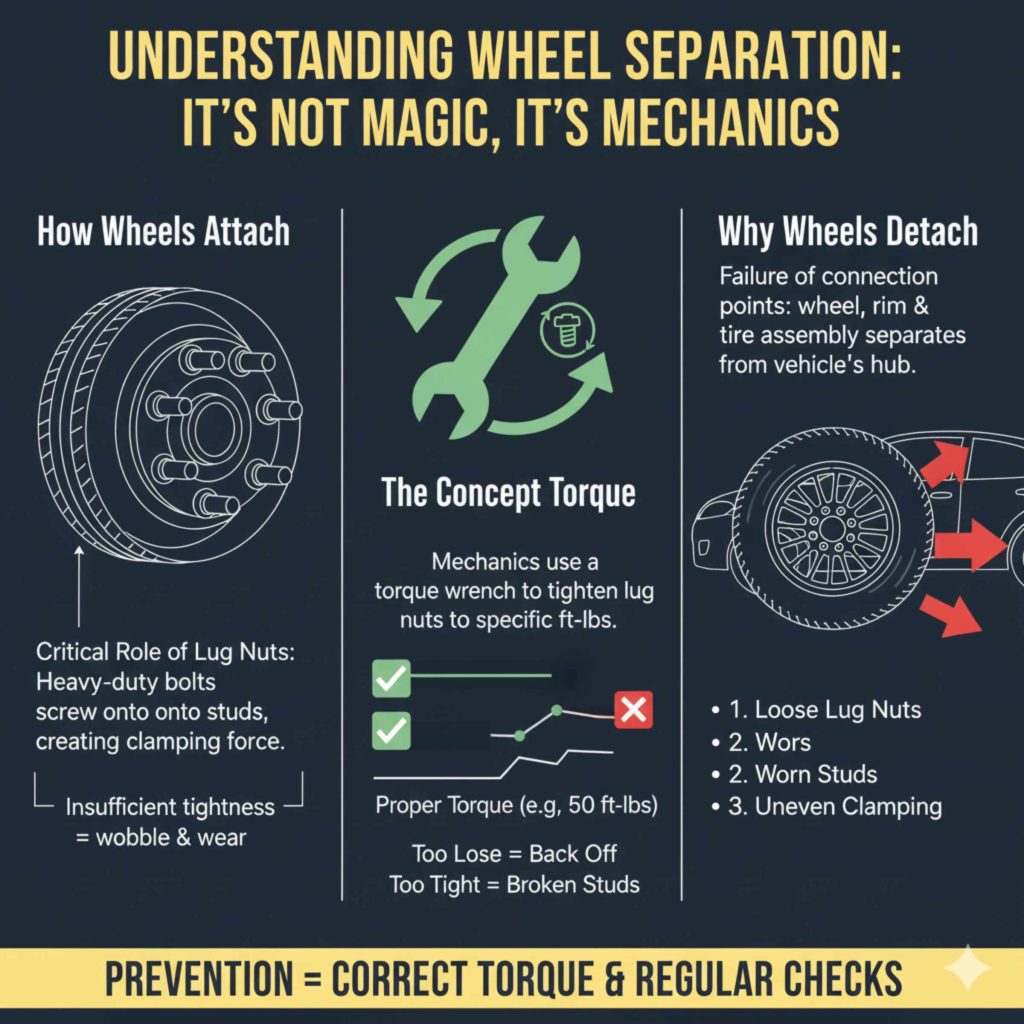

Understanding Wheel Separation: It’s Not Magic, It’s Mechanics

When a tire “comes off,” it means the wheel—including the rim and the tire mounted on it—has completely detached from the vehicle’s hub assembly. This isn’t something the tire itself decides to do. It’s a failure of the connection points that hold the entire assembly onto the car. For beginners, understanding this connection is the first step to prevention.

The Critical Role of Lug Nuts

Your car wheels are held on tight by several heavy-duty bolts called lug nuts. These nuts screw onto studs sticking out from the wheel hub. When tightened correctly, they create immense clamping force, keeping the wheel flush against the mounting surface.

If these lug nuts are too loose, they can wobble. This movement causes wear and tear on the studs, allowing the wheel to eventually shift, press against the hub unevenly, and fall off entirely. It’s a slow failure initiated by insufficient tightness.

The Concept of Torque

Mechanics use a special tool called a torque wrench to tighten lug nuts to a specific tightness, measured in foot-pounds (ft-lbs). This is called torque.

Every car manufacturer specifies an exact torque setting for your lug nuts. Too loose, and they can back off (come undone). Too tight, and you can stretch or break the studs, which creates another serious failure mode.

For example, a standard sedan might require 90 ft-lbs of torque. If the shop only loosely tightens them by hand, they might only reach 50 ft-lbs, which isn’t enough to keep the wheel safe during turns and bumps.

Primary Causes: How Does a Tire Come Off a Car While Driving?

While it sounds catastrophic, the reasons why a wheel detaches are usually straightforward mechanical failures stemming from human error during installation or maintenance.

1. Improper Lug Nut Tightening (The Most Common Culprit)

This is, by far, the number one reason for a wheel separation incident. This usually happens right after a tire rotation, brake job, or flat repair where the wheel has been removed and reattached.

- Hand-Tightening Only: A technician rushes and only tightens the nuts with an impact gun set too low, or worse, just uses a hand wrench without checking the final torque.

- Incorrect Torque Sequence: Lug nuts must be tightened in a specific “star” or “crisscross” pattern. If you tighten them sequentially in a circle, the wheel won’t seat flat against the hub, causing uneven pressure that loosens the nuts over time.

- Failure to Re-Torque: Even if tightened correctly initially, modern alloys and studs can settle shortly after installation. Most quality shops recommend re-checking the torque after about 50 to 100 miles of driving. If this step is skipped, the nuts can loosen just enough to fail.

2. Damaged or Worn Studs and Lug Nuts

The studs—the bolts sticking out of the hub—are designed to handle a specific amount of load.

- Stretched Threads: If the lug nuts were severely over-torqued (too tight) during a previous service, the metal threads on the stud can stretch past their elastic limit. They are weakened and may eventually shear off under driving forces.

- Rust and Corrosion: On older vehicles or those driven in snowy, salted climates, rust can build up around the stud threads or the lug nut seating area. This corrosion prevents the nut from achieving the intended clamping force, even if it feels tight.

- Damaged Threads: If the threads are cross-threaded (started on at an angle), they won’t hold securely, leading to rapid loosening once vibration starts.

3. Physical Damage or Extreme Stress

While less common than installation errors, external forces can sometimes cause a catastrophic failure.

- Severe Pothole or Road Debris Impact: Hitting a massive pothole or large piece of road debris at highway speed can impose a force so sudden and severe that it instantly breaks weakened studs or forces adequately tightened nuts to move.

- Fatigue: High-performance or heavily loaded vehicles can experience metal fatigue on components over many years, though this is rare on standard passenger cars without prior clear warning signs.

Warning Signs: How to Spot Trouble Before It’s Too Late

The good news is that a wheel rarely falls off without giving you several noticeable warnings first. Learning to recognize these signs is your best defense!

Audible Warning Signs

Listen carefully to your car during normal driving. These sounds indicate something is likely loose:

- Clicking or Tapping: A very light, rhythmic clicking sound, usually heard when moving slowly or turning, often means a lug nut is slightly loose and tapping against the stud head or the wheel.

- Grinding or Scraping: If the wheel has shifted enough, it might start rubbing against the suspension components or the brake caliper. This grinding noise is serious and means you need to stop immediately.

- Loud Knocking While Turning: When a wheel becomes severely loose, the weight distribution shifts, causing the wheel assembly to knock against the hub irregularly.

Tactile (Feeling) Warning Signs

Your ability to feel vibrations is crucial for identifying potential issues before they become visible.

- Steering Wheel Vibration: A gentle, pulsing vibration felt through the steering wheel, especially noticeable when moving at speed, is a classic sign of an unbalanced tire or a loose wheel. If it feels harsh or choppy, pull over immediately.

- Vehicle Pulling: As the wheel loosens, it changes the geometry of the axle, causing the car to noticeably pull to one side, often aggressively. This occurs because the loose wheel is applying uneven force.

- Shimmying or Wobbling: You might feel a distinct side-to-side wobble in the driver’s seat or the floorboard, distinct from typical road vibration.

Visual Warning Signs

Before the wheel falls off, you can often spot physical evidence.

If you ever stop for gas or coffee, take 30 seconds to look at your wheels. This quick visual check can save you from a hazard.

| Warning Sign | What It Suggests | Urgency Level |

|---|---|---|

| Lug nuts appear recessed or sticking out unevenly. | Lug nuts are not seated flat; uneven torque. | Medium |

| Visible rust streaks coming from where the lug nuts meet the wheel. | Moisture and movement are occurring between the surfaces. | High |

| The wheel sits slightly further out or at a different angle than the others. | Studs may be broken or the wheel is severely misaligned. | Critical |

Essential Prevention: Torquing Wheels Like a Professional

The vast majority of wheel separations are preventable by simply following proper re-installation procedures. This is knowledge every car owner should have, whether you plan to do the work yourself or just want to know if your mechanic did it right.

Tools You Need for Proper Wheel Security

You don’t need thousands of dollars worth of gear, but a torque wrench is a non-negotiable safety tool for wheel work.

- Torque Wrench: Must be calibrated and capable of measuring the required ft-lbs for your specific vehicle.

- Lug Wrench or Breaker Bar: For getting the nuts off initially.

- Owner’s Manual: This contains the specific torque specification for your vehicle. (You can often find this information online too, such as on manufacturer service sites recognized by industry bodies).

- Wire Brush: To clean any rust or dirt off the wheel mounting surface and the studs before reassembly.

Step-by-Step: Reinstalling a Wheel Correctly

If you ever change a flat tire yourself, follow these steps rigorously to ensure the wheel stays put.

Step 1: Cleaning and Inspection

Remove the old wheel. Use the wire brush to clean the hub mating surface (where the wheel mounts) and wipe the wheel mounting surface clean. Inspect every stud for signs of damage or stretching. If a stud looks bent or has damaged threads, it must be replaced before continuing.

Step 2: Hand-Start the Lug Nuts

Place the wheel onto the studs. Thread all lug nuts onto the studs by hand until they are snug. This prevents cross-threading. If you feel resistance early on, stop and re-align the nut.

Step 3: The Crisscross Pattern Tightening (Snug Only)

Using your breaker bar or impact gun (set on a low setting), tighten the nuts just until they securely hold the wheel against the hub. You must follow a star or crisscross pattern. If you have five nuts, tighten nut 1, then skip to nut 3, then 5, then 2, then 4.

Step 4: Final Torque Application (The Safety Step)

Set your torque wrench to the specification found in your owner’s manual. Go around the star pattern again, tightening each lug nut once to the exact torque setting. Do not “go around twice” without resetting the torque wrench; this can lead to over-torquing the first few nuts.

Step 5: The Mandatory Re-Torque Check

This is the forgotten step that prevents most roadside failures after service. Drive the car for 50 to 100 miles. Then, park safely and use your torque wrench (set to the correct value) to check every single lug nut again. If any nut turns even slightly before the wrench clicks, it was loose. Re-torque it to specification.

Aftermarket Wheels and High-Performance Situations

If you have upgraded your car with custom or aftermarket wheels, you introduce a variable that requires extra diligence, as those wheels may not sit identically to factory wheels.

Conical vs. Acorn Seat Lug Nuts

Lug nuts are shaped on the bottom where they contact the wheel. This shape is called the seat. If you change wheels, you must ensure the new wheel is designed for the lug nuts you are using.

| Lug Nut Seat Type | Description | Used With |

|---|---|---|

| Acorn (or Conical) Seat | Tapers to a point, offering a secure seating angle. | Most factory wheels and many aftermarket wheels. |

| Ball (or Radius) Seat | Has a rounded bottom that sits flush in a curved depression. | Commonly found on many factory steel or aluminum wheels (e.g., Honda, older Fords). |

| Mag Seat (Flat Seat) | Has a flat contact surface, usually paired with a small washer. | Less common on modern cars but sometimes used with aftermarket hub-centric rings. |

If you install a lug nut with a conical seat into a wheel designed for a ball seat, the nut effectively only touches a very small ring of metal, leading to rapid loosening once vibration starts. Always match the seat type to the wheel. If you are unsure, consulting a professional wheel shop or checking resources from organizations like the SAE International (Society of Automotive Engineers) on fastener retention is wise.

Hub-Centric vs. Lug-Centric Mounting

Modern cars generally use hub-centric mounting. This means the wheel fits snugly over a perfectly machined center hub on your car, ensuring the wheel is perfectly centered.

If you use spacers or wheels that are not hub-centric (known as lug-centric), the entire weight and centering of the wheel rely solely on the lug nuts. This puts far more shear stress on the lug nuts and studs, greatly increasing the risk of loosening if the torque isn’t absolutely perfect and checked frequently.

What to Do Immediately If You Feel a Wheel Coming Loose

If you are driving and experience one of the strong warning signs—especially a severe pull, heavy vibration, or knocking noise—you must act calmly and immediately to ensure safety.

The Emergency Pull-Over Procedure

1. Stay Calm and Grip Firmly: Hold the steering wheel tightly with both hands. If the car pulls hard to the left, you must steer slightly to the left to keep the vehicle straight. Do not overcorrect.

2. Gently Reduce Speed: Take your foot off the gas pedal immediately. Do not slam on the brakes, as hard braking can cause the already loose wheel assembly to shift violently and separate instantly.

3. Signal and Move Over: Turn on your hazard lights. Carefully begin to guide the car toward the shoulder or the nearest safe pull-off area, using slight steering inputs.

4. Brake Lightly (If Necessary): Once you are moving slowly (under 20 mph) and are near the shoulder, gently apply the brakes to bring the car to a complete stop on level, firm ground, far away from traffic.

5. Do Not Drive Further: If you suspect a wheel is loose, do not attempt to drive even a short distance to a garage. Continuing could lead to the wheel completely detaching, causing body damage, or worse.

Once stopped, you should inspect the issue. If you have a jack and the right tools, you can attempt the re-torque procedure (Steps 1–5 above) if you suspect minor loosening. If a stud is clearly broken or the wheel appears obviously askew, call for roadside assistance immediately. Do not attempt to drive it flat on the rim or drive it to a shop with an apparent wheel separation risk.

FAQ: Beginner Questions About Wheel Safety

Q1: How often should I check my lug nut torque after getting new tires installed?

A: You should check the torque after driving 50 to 100 miles following any service where the wheels were removed. After that initial check, it is good practice to visually inspect and lightly check them every few months as part of your regular proactive maintenance.

Q2: Can a car wheel fall off in the rain or cold weather?

A: Weather itself does not cause the failure, but very cold temperatures can cause metal components to contract slightly, potentially loosening already marginal connections. Rust accelerated by road salt in winter can also contribute to failed seating.

Q3: What is the danger of an improperly tightened lug nut?

A: The primary danger is wheel separation while driving, which can cause you to lose control or result in significant damage to your car’s bodywork, suspension, and brakes if the wheel comes off at speed.

Q4: If my wheel seems ‘wobbly,’ is that the same as it being loose?

A: Yes, a wobble or shimmy felt while driving is strongly indicative that the wheel isn’t sitting perfectly flush against the hub, usually due to unevenly tightened or loose lug nuts. This needs immediate attention.

Q5: Do I need a torque wrench if I only use a standard lug wrench?

A: While you can technically use only a standard wrench, you absolutely need a torque wrench for the final tightening stage to meet manufacturer specifications. Relying only on physical feel with a standard wrench often results in nuts being too loose or dangerously overtightened.

Q6: Does using an impact gun at the shop guarantee the nuts are tight enough?

A: No. Impact guns are great for removal, but unless they are equipped with a torque stick (a limiter) or the technician manually checks it afterward, they often apply too much or too little force. Always ask your service provider to confirm lug nut torque has been verified with a calibrated torque wrench after reinstallation.

Final Thoughts on Keeping Your Wheels Attached

The question, “how does a tire come off a car while driving?” has a clear answer: usually because the nuts holding it on were not at the correct tightness. This is not a random mechanical failure; it’s a maintenance oversight. By understanding the vital role of proper torquing, paying attention to the early warning signs like vibrations or clicking sounds, and always performing that crucial re-torque after any brake or tire service, you take complete control of this safety issue. Being proactive about your wheel security ensures that your driving experience remains predictable, safe, and worry-free.