If you suspect a bad transmission control solenoid, look for sudden, harsh gear shifts, slipping gears, the transmission sticking in one gear, illuminated check engine lights, or failure to shift at all. These are the most common signs that this vital electronic part needs attention.

That lurching feeling when your car shifts gears, or maybe no shifting at all? It can be frustrating and frankly, a little scary when your automatic car starts acting up. Many times, the culprit hiding behind these weird shifts is a small but mighty component called the Transmission Control Solenoid (TCS). Don’t worry; figuring out if one of these solenoids has gone bad doesn’t require a mechanic’s degree. With a few simple checks, you can pinpoint the issue. We are going to walk through every warning sign and simple test you can perform to know for sure. Let’s get you back on the road confidently!

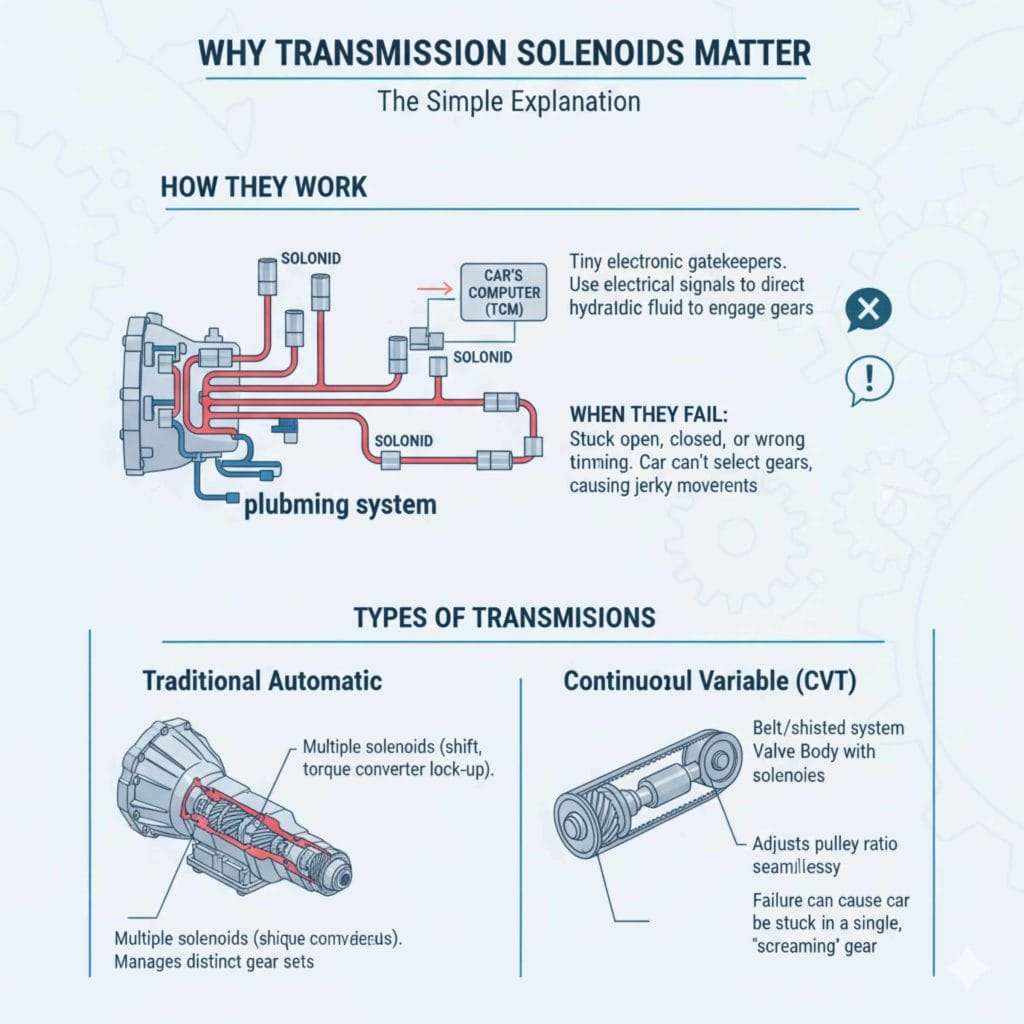

Why Transmission Solenoids Matter (The Simple Explanation)

Think of your automatic transmission like a complicated set of plumbing pipes, managing fluid pressure to make gear changes smooth. The solenoids are the tiny electronic gatekeepers in that system. They are basically small valves that use electrical signals from your car’s computer (the Transmission Control Module or TCM) to direct the hydraulic fluid to engage specific gears (like 1st, 2nd, or Drive).

When a solenoid fails, the gate stays stuck open, stuck closed, or opens at the wrong time. Since the computer relies on these little gates to open and close precisely, if one sticks, your car can’t select the right gear at the right time. This causes all those jerky movements or the inability to move at all.

Automatic vs Continuously Variable Transmissions (CVTs)

While the basic principle is the same—controlling fluid flow—the setup differs slightly:

- Traditional Automatic Transmissions: Usually contain multiple solenoids (shift solenoids, torque converter lock-up solenoids) that manage distinct gear sets.

- CVTs: These use belt/pulley systems and often rely on a sophisticated Valve Body assembly containing several precisely controlled solenoids to adjust the pulley ratio seamlessly. If a solenoid fails in a CVT, the feeling is often dramatic, like the transmission is stuck in a single, screaming gear.

The Top 7 Signs Your Transmission Control Solenoid Is Failing

Recognizing the symptoms early can save you money by preventing wider damage to your transmission. Listen to your car; it usually tells you what’s wrong! Here are the most common indicators that it’s time to look closely at your solenoids.

1. Harsh or Erratic Shifting (The Jerk Test)

This is the headline symptom. If your vehicle “slams” into the next gear instead of smoothly transitioning, a solenoid is likely slow or failing to regulate fluid pressure correctly.

- Slamming into Drive: When you shift from Park to Drive, you might feel a noticeable, forceful “thunk” or “clunk” instead of a gentle engagement.

- Rough Upshifts/Downshifts: While driving, the car might hesitate momentarily, then suddenly lurch forward or backward as it finally engages the next gear. This is often due to a shift solenoid not opening or closing fast enough.

2. Gear Slipping or Staying Stuck in One Gear

If the solenoid responsible for engaging a specific gear fails entirely, that gear may become completely unavailable. Alternatively, the transmission might slip out of gear while driving.

- Slipping: You press the gas, the engine revs high, but your speed doesn’t increase proportionally. This means the gear isn’t fully engaged—the solenoid isn’t holding the required pressure.

- Stuck in Gear: If you feel like you are stuck in second gear, no matter how fast you drive or how gently you shift, a solenoid may be frozen in the open or closed position.

3. Illumination of the Check Engine Light (CEL)

Modern cars are smart. The onboard diagnostic system (OBD-II, required on all US vehicles since 1996) constantly monitors the solenoids’ electrical resistance and performance. If a solenoid isn’t responding as commanded, the system stores a trouble code (DTC).

While the CEL can mean anything from a loose gas cap to a major engine failure, transmission-related codes (often P07XX codes) specifically point toward solenoid or valve body issues. You will need an OBD-II scanner to read these codes, which is an excellent first diagnostic step for any beginner DIYer.

4. Fluid Leaks Near the Transmission Pan

Solenoids are located inside the transmission, usually mounted on or near the valve body, accessible from under the car by removing the transmission pan. If the seals around these solenoids or the solenoid’s mounting point begin to degrade, you might see reddish or brownish fluid leaking onto your driveway.

A quick note: Transmission fluid leaks can also come from pan gaskets or cooler lines. The key here is observing if the leak is localized near where the wiring harness enters the transmission case, though this can be hard to pinpoint without looking underneath.

5. Poor Fuel Economy

If your transmission cannot shift into the highest gears efficiently (overdrive), your engine will run at higher RPMs for longer periods while cruising at highway speeds. This forces the engine to burn more fuel.

While many things impact MPG, a transmission stuck in a lower gear because of a stuck solenoid can cause a noticeable, sustained drop in your fuel economy.

6. Transmission Overheating

When solenoids fail to manage fluid flow correctly, the fluid inside the transmission can become “churned” or diverted improperly. This leads to increased internal friction, which generates excess heat. Overheated transmission fluid loses its ability to lubricate and cool effectively, which is a major danger to the entire transmission.

In some vehicles, a dedicated temperature sensor will trigger an alert, but often you’ll just notice that the vehicle seems sluggish after driving for a while, especially in stop-and-go traffic.

7. Unusual Transmission Noises

While grinding noises usually mean mechanical gear damage, solenoid issues can sometimes cause whining or buzzing sounds, especially when the TCM is trying—and failing—to command a shift. If you hear a persistent electronic buzzing noise coming from the transmission area when you put the car in gear, it could indicate an electrical short or failure within a solenoid coil.

Diagnostic Steps: How to Test a Solenoid

Once you suspect a problem, the next step is confirming if it’s truly an electrical solenoid failure. This requires a bit more technical comfort, but we will keep it simple. For more detailed system diagnostics, always refer to the specific repair manual for your vehicle make and model, as procedures vary widely.

Safety First: Always set your parking brake firmly. If you are lifting the car, use sturdy jack stands rated for the vehicle’s weight. Never work under a vehicle supported only by a hydraulic jack.

Test 1: Checking Diagnostic Trouble Codes (DTCs)

This is the easiest and most definitive starting point for modern vehicles.

- Obtain an OBD-II Scanner: You can buy a basic one for under $50, have one borrowed from an auto parts store (many lend them out for free diagnostic use), or visit a local shop that reads codes for free (like many major chain auto stores).

- Locate the Port: The diagnostic port is usually located under the dashboard on the driver’s side, near the steering column.

- Scan for Codes: Plug in the scanner, turn the key to the “ON” position (engine off), and follow the scanner’s prompts to “Read Codes.”

- Analyze Transmission Codes: Look specifically for codes in the P07XX range. For example, a code like P0750 usually points directly to Shift Solenoid “A” circuit malfunction. These codes often tell you exactly which solenoid is malfunctioning.

Test 2: Electrical Testing (Resistance Check)

Solenoids are simple electrical coils. They should have a specific electrical resistance (measured in Ohms) when tested. If the resistance is too high (open circuit) or too low (short circuit), the solenoid is bad.

Tools Needed:

- Digital Multimeter (set to Ohms or Resistance Ω)

- Wiring diagram for your vehicle (essential for knowing where the solenoid connector is)

- Basic hand tools

Procedure:

- Locate the Solenoid Connector: In many vehicles, you can access shift solenoids by removing the transmission pan. For some models, they are externally accessible through a dedicated wiring harness connected to the side of the transmission housing.

- Disconnect the Harness: Carefully unplug the electrical connector leading to the solenoid you suspect is faulty.

- Test for Continuity/Resistance: Place the multimeter probes onto the two connection points for that specific solenoid. Consult your vehicle’s service manual for the expected resistance range (it is often between 5 and 20 Ohms, but this varies greatly).

- Interpret the Results:

- Good Solenoid: Reads within the manufacturer’s specified Ohms range.

- Bad Solenoid (Open Circuit): Reads “OL” (Over Limit) or infinity. The coil wire is broken.

- Bad Solenoid (Short Circuit): Reads near zero Ohms. The coil wires are touching.

For reliability scores on automotive components, checking resources from bodies like the U.S. Department of Transportation’s National Highway Traffic Safety Administration (NHTSA) often highlights the importance of proper electrical function for vehicle safety systems.

Test 3: Pressure Testing (Advanced/Professional)

While less practical for beginners, true transmission diagnosticians verify solenoid function by checking the actual hydraulic line pressure that the solenoid controls. If the TCM commands a shift, but the pressure regulator connected to that solenoid doesn’t change the pressure reading on the gauge where it should, the solenoid has failed its command cycle.

Solenoid Replacement Overview: Is It a DIY Job?

Replacing a transmission control solenoid is generally considered an intermediate DIY task. It often requires managing the transmission fluid and dealing with tight spaces.

When You Might Be Able to Do It Yourself:

If the solenoid is externally mounted or easily accessible by removing only the transmission pan (which is common for many rear-wheel-drive cars and some front-wheel-drive models), it can be a manageable weekend project, provided you are comfortable draining and refilling several quarts of specialized transmission fluid.

When to Call a Professional:

If the solenoid is deep inside the valve body, requiring partial or full removal of the transmission casing or specialized tools to remove internal snap rings, it moves firmly into the professional repair category. Incorrect reassembly or incorrect fluid handling can quickly destroy an automatic transmission.

Here is a quick comparison to help you decide:

| Accessibility Location | Typical DIY Rating | Notes |

|---|---|---|

| External Housing (Visible Wires) | Easy/Beginner | Often just involves removing a few bolts and unplugging the harness. |

| Under Transmission Pan | Intermediate | Requires draining fluid, dropping the pan, and careful re-gasketing. |

| Deep Within Valve Body | Advanced/No | Requires removal of the valve body, risking damage to many internal check balls and springs. |

Understanding Solenoid Types and Their Failure Modes

Not all solenoids do the same job. Knowing which one might be failing helps narrow down the symptoms you are experiencing.

Shift Solenoids (SS)

These are the workhorses, responsible for commanding the actual gear change (e.g., shifting from 2nd to 3rd).

- Failure Symptom: Harsh shifting, skipping gears, or getting stuck in a single gear.

- Testing Complexity: Usually requires pan removal to access.

Torque Converter Lock-Up (TCL/TCC) Solenoid

This solenoid controls the fluid coupling in the torque converter, which locks up at highway speeds to improve fuel economy (like a manual clutch engaging). When locked, the engine and transmission are mechanically linked.

- Failure Symptom: Vibration or shuddering at steady highway speeds (when it should be locked up) or excessive heat/poor MPG because it never engages.

- Testing Complexity: Often easier to access than shift solenoids, sometimes located near the case connector plugs.

Pressure Control Solenoids (PCS) / Line Pressure Solenoids

These solenoids manage the overall hydraulic line pressure in the transmission. Proper pressure is vital for firm, clean shifts and preventing clutch drag.

- Failure Symptom: Overall soft, weak, or slipping shifts across all gears, or severe low-speed shuddering.

- Testing Complexity: Often the most critical and usually located centrally on the valve body.

Preventative Care to Extend Solenoid Life

Since solenoids are sensitive to heat and dirty fluid, the best way to avoid knowing if one is bad is by practicing excellent maintenance!

- Change Transmission Fluid Regularly: Dirty, burnt fluid breeds sludge that clogs the tiny passages leading to the solenoids and contaminates the internal circuits. Follow your manufacturer’s recommended schedule for fluid and filter changes—this is far cheaper than a new solenoid!

- Use the Right Fluid: Never substitute fluids. Modern transmissions require highly specific friction modifiers and viscosities (like ATF+4, Dexron VI, or specific CVT fluids). Using the wrong fluid causes the solenoids to operate inefficiently.

- Monitor Temperature: If you frequently tow or drive aggressively, consider installing a transmission temperature gauge. Keeping the temperature in check is the single best way to protect all internal components, including solenoids.

- Address Leaks Immediately: Low fluid levels starve the hydraulic system, which forces solenoids to work harder to maintain pressure, leading to premature electrical failure.

Frequently Asked Questions (FAQ) About Bad Solenoids

Q1: Can I drive my car if a transmission solenoid is bad?

A: It depends on which solenoid failed. If it’s a minor solenoid (like a TCC solenoid causing a slight shudder), you can often drive cautiously for a short time. However, if a shift solenoid fails completely, and the car is stuck in gear, driving aggressively or driving long distances can cause major overheating and damage to clutch packs. Stop driving if the harshness is severe.

Q2: How much does it cost to replace a transmission control solenoid?

A: Costs vary widely. For a single, easily accessible solenoid replacement performed by a professional, you might expect to pay between $300 and $650, parts and labor included. However, if multiple solenoids fail, mechanics often recommend replacing the entire valve body assembly, which can run $1,000 or more.

Q3: How long do transmission solenoids usually last?

A: With proper maintenance (regular fluid changes), solenoids can last the lifetime of the vehicle, often 150,000 miles or more. Failure is usually hastened by neglected fluid, overheating, or electrical surges.

Q4: If I replace a solenoid, will I need to reprogram my car?

A: Often, no. Most basic shift solenoids are “plug-and-play” electrical components that the Transmission Control Module (TCM) recognizes instantly. If you replace the entire valve body or if the TCM has learned poor shift patterns due to the old solenoid, you might benefit from a simple “TCM Relearn Procedure,” which some shops perform for free or a minimal charge.

Conclusion: Catch the Problem Early, Protect Your Transmission

A failing transmission control solenoid may be small, but its impact on how your car drives is anything but minor. From harsh, jerky shifts and slipping gears to warning lights and poor fuel economy, your vehicle gives clear signals when something isn’t right. The key takeaway from this guide is simple: don’t ignore those warning signs.

By understanding how solenoids work, recognizing the most common symptoms, and using basic diagnostic steps like scanning for trouble codes, you can often identify a solenoid issue before it snowballs into major transmission damage. In many cases, addressing a bad solenoid early can mean a relatively affordable repair instead of a costly rebuild or replacement.

Regular maintenance—especially using the correct transmission fluid and changing it on schedule—is your best defense against solenoid failure. Clean, cool fluid keeps these electronic valves working smoothly and extends the life of your entire transmission.

If your car starts shifting strangely, trust your instincts and investigate sooner rather than later. Whether you decide to tackle the repair yourself or bring it to a professional, being informed puts you in control. A little attention now can save you a lot of money, stress, and downtime later—and keep you driving confidently for miles to come!