You can often fix common Transmission Control Module (TCM) issues via simple procedures like clearing trouble codes, checking electrical connections, or refreshing the module’s software. Replacing the TCM is not always necessary; many “failures” are just communication problems that are surprisingly easy to solve yourself.

If your automatic transmission is slamming into gear, shifting erratically, or refusing to engage, the Transmission Control Module (TCM) might be the culprit. This little computer is the brain of your transmission, telling the gears exactly when and how hard to shift. When it acts up, driving becomes frustrating and sometimes unsafe. But before you rush to an expensive repair shop, know this: many TCM problems are simpler than they seem. We are going to walk through proven, essential fixes that everyday drivers can try. Fixing a TCM issue often comes down to a simple check or a quick reset, saving you time and a lot of money. Let’s get your smooth ride back!

Understanding the TCM and Its Role

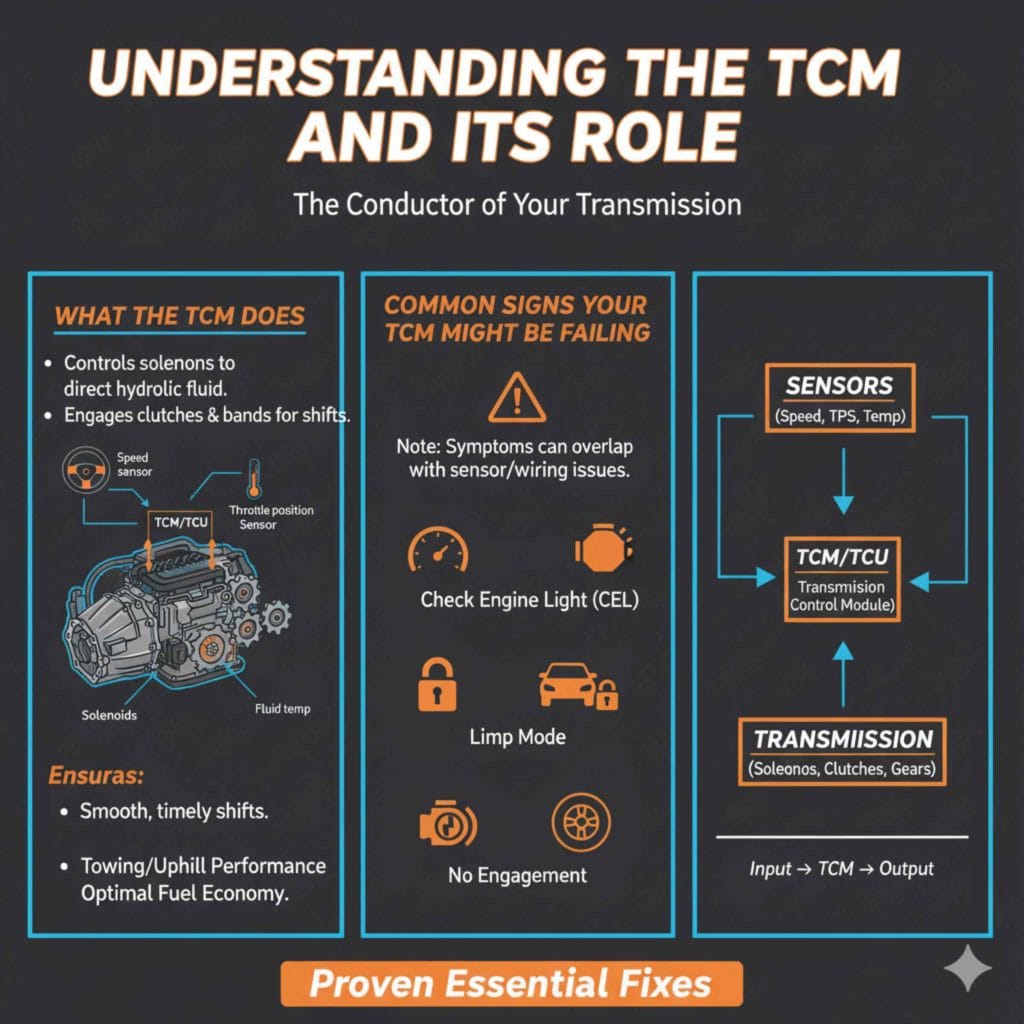

The Transmission Control Module (TCM), sometimes called the Transmission Control Unit (TCU), is vital. Think of it as the conductor of a very precise orchestra—the transmission itself. It takes information from many sensors (like speed, throttle position, and fluid temperature) and decides the perfect moment to shift gears.

What Does the TCM Actually Do?

The TCM controls the electronic solenoids within your transmission. These solenoids act like tiny valves, directing hydraulic fluid to engage or disengage the clutches and bands needed for gear changes.

A healthy TCM ensures:

- Smooth, timely upshifts and downshifts.

- Correct performance when towing or driving uphill.

- Optimal fuel economy based on driving conditions.

Common Signs Your TCM Might Be Failing

It is important to distinguish between a true TCM failure and a simple sensor or wiring issue. Many symptoms overlap.

Watch out for these common warnings:

- Erratic Shifting: The transmission shifts too early, too late, or “slams” into gear unexpectedly.

- Check Engine Light (CEL) or Transmission Light: These illuminate because the TCM is sending error signals.

- Limp Mode: The car locks into a single gear (usually second or third) to protect the transmission from further damage.

- Inability to Shift: The vehicle remains stuck in neutral or park.

- No Engagement: The engine revs up, but the car refuses to move when put into Drive or Reverse.

Step 1: The Easiest First – Clearing the Codes

The most overlooked and easiest fix for any module problem is simply clearing the error codes stored in the vehicle’s computer systems. Sometimes, a sensor glitch or a fleeting electrical spike sets a code that the TCM remembers, causing it to behave poorly even after the initial issue is gone.

Tools You Will Need

- An OBD-II Scanner (Basic code readers are inexpensive and excellent for DIYers).

- A digital clock (optional, for timing the battery disconnect).

Method A: Using an OBD-II Scanner

A dedicated scanner is the best way because it can often target codes specifically in the TCM, rather than just the main Engine Control Unit (ECU).

- Locate the Port: The OBD-II port is usually under the dashboard on the driver’s side.

- Connect and Scan: Plug in the scanner. Turn the ignition key to the “ON” position (do not start the engine). Follow the scanner’s directions to read the codes.

- Identify Transmission Codes: Look for codes in the ‘P’ or ‘U’ range, or codes specifically labeled as Transmission Control Module failures (often starting with P07xx).

- Erase Codes: If you have done your preliminary checks (like ensuring fluid levels are correct) and are confident the issue was transient, use the scanner’s “Erase Codes” or “Clear Memory” function.

- Test Drive: Turn the car off for five minutes, then start it up and take a short, easy test drive to see if the shifting behavior has returned to normal.

Method B: The Battery Reset (A Hard Reset)

Disconnecting the battery forces all modules, including the TCM, to completely power down and reboot. This can sometimes clear minor software glitches.

- Safety First: Turn off the car and remove the key. Engage the parking brake.

- Disconnect the Negative Terminal: Using a wrench (usually 10mm), carefully loosen and remove the nut holding the negative (black) battery cable clamp to the battery post.

- Isolate the Cable: Ensure the cable end cannot accidentally touch the battery post.

- Wait: For many modern cars, waiting 15 to 30 minutes is recommended to allow all residual power capacitors to fully drain. You can use this time to check connections later.

- Reconnect: Reattach the negative cable securely.

- Relearn Period: After reconnecting, drive the car gently for about 10 to 20 miles. The TCM needs this time to “relearn” your driving habits and adapt to the new zero-state it was just forced into. Shifting might feel different initially.

Expert Note: While a battery reset is easy, it will erase radio presets and potentially affect security systems. Always consult your owner’s manual if you are unsure about your vehicle’s specific procedures for battery disconnection.

Step 2: Inspecting the Wiring and External Connections

The TCM rarely fails internally without an obvious external trigger, especially in older or higher-mileage cars. Corrosion, vibration, or heat can damage the harness connecting the TCM to the rest of the car.

Locating the TCM

The location varies wildly. It might be:

- Under the dashboard near the glove box.

- In the engine bay (though less common due to heat).

- Under the center console or near the shifter assembly.

Check your vehicle’s service manual for the exact location of the Transmission Control Module.

Connector Inspection Procedure

This is where most electrical gremlins hide.

- Visual Check: Look for obvious signs of damage—crushed wires, chafed insulation, or melted plastic connectors near the TCM.

- Disconnect Connector: Carefully unlatch the main wiring harness connector(s) attached to the TCM. On many modules, this involves pulling a locking tab or lever.

- Check Pins for Corrosion: Look closely at the metal pins inside the connector. Green, white, or powdery buildup indicates corrosion, usually caused by moisture intrusion.

- Cleaning Corroded Pins: If corrosion is present, use a small amount of electrical contact cleaner (available at most auto parts stores) and a soft, plastic-bristled brush or a dedicated small wiring brush. Never use sandpaper or metal tools, as this can scratch the delicate plating off the pins.

- Inspect Wires for Integrity: Gently tug on individual wires where they enter the connector housing. If they pull loose, the wire has frayed internally, requiring professional repair or harness replacement.

- Reconnection: Plug the harness back in firmly until you hear or feel a distinct click. A loose connection is as bad as a corroded one.

The Grounds Connection

Ground wires provide a path for electricity to return to the battery. A poor ground connection can cause erratic electrical readings across all systems, including the TCM.

Find the main grounding points for the engine/transmission harness. These are usually heavy, black wires bolted directly to the chassis or engine block. Ensure these bolts are tight and that there is no rust or paint between the wire terminal and the metal surface.

Step 3: Checking Transmission Fluid and Sensors

Sometimes the TCM is behaving because the data it is receiving is incorrect, or the physical environment inside the transmission is compromised.

Fluid Level and Condition

Low or burnt transmission fluid can cause slippage, which the TCM interprets as mechanical failure, leading it to set codes.

- Check Level: Follow your manufacturer’s specific procedure (some must be checked while running in Park, others turned off). The level must be correct.

- Check Color: Good ATF (Automatic Transmission Fluid) is typically bright red or pinkish. If the fluid is dark brown, black, or smells distinctly burnt, that indicates internal clutch damage, which the TCM will react to.

Input and Output Speed Sensors (ISS/OSS)

These small sensors tell the TCM how fast the input shaft (engine side) and output shaft (wheel side) are moving. If one fails, the TCM cannot properly time shifts.

If your diagnostic scanner showed specific codes related to ISS (Input Speed Sensor) or OSS (Output Speed Sensor), replacing that sensor is often a cheaper fix than replacing the entire module. These sensors are usually bolted directly onto the transmission casing or near the output shaft.

| Symptom | Likely Culprit (Easier Fix) | TCM Fix Required? |

|---|---|---|

| Rough shifts, no noticeable speed sensor fault codes. | Corroded harness connector or software bug. | Maybe, after cleaning/reset. |

| Car slips badly, smells burnt. | Low fluid or internal mechanical damage. | Unlikely the TCM is the root cause. |

| Codes P0720, P0721 (Output Speed Sensor Circuit). | Faulty OSS sensor or open circuit wiring. | No, replace the sensor first. |

Step 4: Software Reflash and Updates

In modern vehicles, the programming (firmware) inside the TCM can become corrupt, outdated, or incompatible with other modules (like the Engine Control Unit or Body Control Module) after a major software update elsewhere in the car. This is a frequent issue manufacturers address with Technical Service Bulletins (TSBs).

What is a TCM Reflash?

A reflash involves connecting specialized diagnostic equipment to the vehicle’s main communication port (the OBD-II port) and downloading the latest, manufacturer-approved operating software directly onto the TCM’s memory chip. This is essentially giving the TCM a fresh operating system.

Can I Do a Reflash at Home?

Generally, no. Reprogramming a sensitive module like the TCM requires high-end, factory-level scan tools and a constant, stable power supply, as interrupting the flash process can permanently “brick” (destroy) the module, forcing a costly replacement.

How to Proceed:

- Check for TSBs: Search online using your vehicle’s Year, Make, Model, and the TCM error code along with the term “TSB” (Technical Service Bulletin). If a TSB exists, your dealer or independent shop can apply the fix.

- Visit a Specialist: If a reset and inspection didn’t work, ask a reputable independent transmission specialist or dealership to check for available software updates for your TCM. This is significantly cheaper than a full module replacement.

For reference on how complex vehicle computers work, organizations like the National Highway Traffic Safety Administration (NHTSA) emphasize the increasing interdependence of these control units.

When All Else Fails: Considering Replacement or Repair

If you have cleared codes, inspected every visible connection, checked fluid, and confirmed no easy sensor swap solved the problem, you are likely looking at internal failure or deep software corruption that requires professional intervention.

Repair vs. Replace the TCM

When a TCM truly fails internally (e.g., a burned-out circuit board), you have two main options:

- Replacement: Buying a brand-new module from the dealer is the most expensive option. A refurbished aftermarket unit is often a good balance of cost and reliability. Crucially, any replacement TCM must be programmed to recognize your car’s specific VIN and mileage, a process called “virginizing” or “programming,” which usually must be done by a professional.

- TCM Repair Service: Many specialized electronics repair shops offer mail-in services. You send them your faulty module, they fix the known failure points on the board, and mail it back. This is often much cheaper than buying new and retains your car’s original programming data.

DIY Replacement Warning

Swapping a TCM yourself is mechanically easy (usually unbolt three screws and unplug the harness), but the required programming makes it unsuitable for most beginners.

If you purchase a used TCM, you will almost certainly need to bring it to a shop or use a specialized tool to program it to your vehicle. Installing an incorrectly programmed TCM can cause immediate drivability issues or even damage the transmission mechanically.

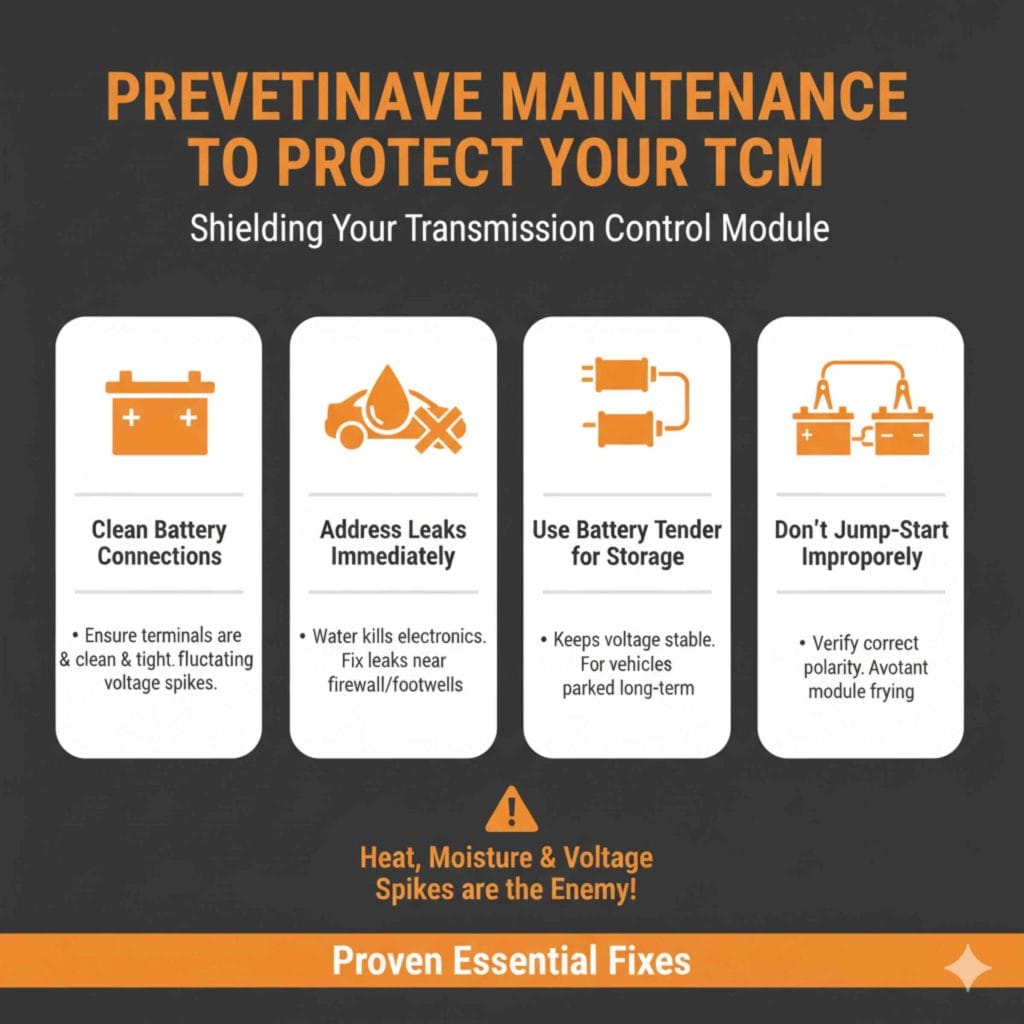

Preventative Maintenance to Protect Your TCM

Protecting the TCM means protecting its environment. Since the TCM is an electronic device, heat, moisture, and voltage spikes are its worst enemies.

Protect your investment with these simple steps:

- Maintain Clean Battery Connections: Ensure your battery terminals are clean and tight. Bad battery performance leads to fluctuating voltage, stressing all vehicle modules.

- Address Leaks Immediately: Water intrusion is a major TCM killer. If you notice moisture leaking near the firewall, footwells, or under the hood where the TCM sits, trace and fix the leak swiftly.

- Use a Battery Tender for Storage: If the vehicle sits for long periods, use a quality battery tender to keep the voltage stable.

- Don’t Jump-Start Improperly: When jump-starting another car or having your car jumped, ensure the polarity (+ to +, – to -) is correct and that the connection is firm. Voltage spikes can fry electronic modules instantly.

Frequently Asked Questions (FAQs)

Q1: How long does it take to fix a TCM issue if I do it myself?

If the repair involves clearing codes or cleaning connectors (Steps 1 and 2), it can take as little as 30 minutes. If you need to replace a sensor, allow half a day. If a reflash is needed, it typically takes a professional an hour or two.

Q2: Can I override the TCM to drive home if the car is stuck in limp mode?

In most modern vehicles, no. Limp mode is a safety feature designed to protect the transmission from self-destruction due to a detected fault. Trying to manually force shifts against the module’s command can cause severe internal damage.

Q3: Is it safe to drive with a bad TCM?

It can be unsafe. Erratic shifting causes sudden changes in speed and may lead to complete transmission failure. If the module is malfunctioning intermittently, dangerous situations can arise, especially during highway merging or passing.

Q4: How much does a TCM reflash cost compared to replacement?

A reflash usually costs between $100 and $250 at a specialist or dealer. A new TCM, plus the labor and programming required for installation, can easily run $800 to $2000 or more, depending on the car model.

Conclusion

Transmission Control Module problems often sound intimidating, but as this guide shows, many issues are not true module failures at all. Erratic shifting, limp mode, or warning lights are frequently caused by temporary software glitches, poor electrical connections, low or degraded transmission fluid, or faulty sensors feeding bad data to an otherwise healthy TCM. By starting with the simplest fixes—clearing codes, performing a hard reset, and inspecting wiring and grounds—you can often restore normal shifting with minimal cost and effort.

Only after these basic checks should you move toward more advanced solutions like software reflashing or professional diagnostics. Even then, a reflash or targeted sensor replacement is usually far cheaper than immediately replacing the entire module. Full TCM replacement should be treated as a last resort, reserved for confirmed internal failures that cannot be corrected through resets, repairs, or updates.

In short, a methodical, step-by-step approach can save you significant money and prevent unnecessary repairs. With a little patience and the right checks, many TCM “failures” turn out to be manageable problems—bringing your transmission back to smooth, reliable operation without an expensive trip to the shop.