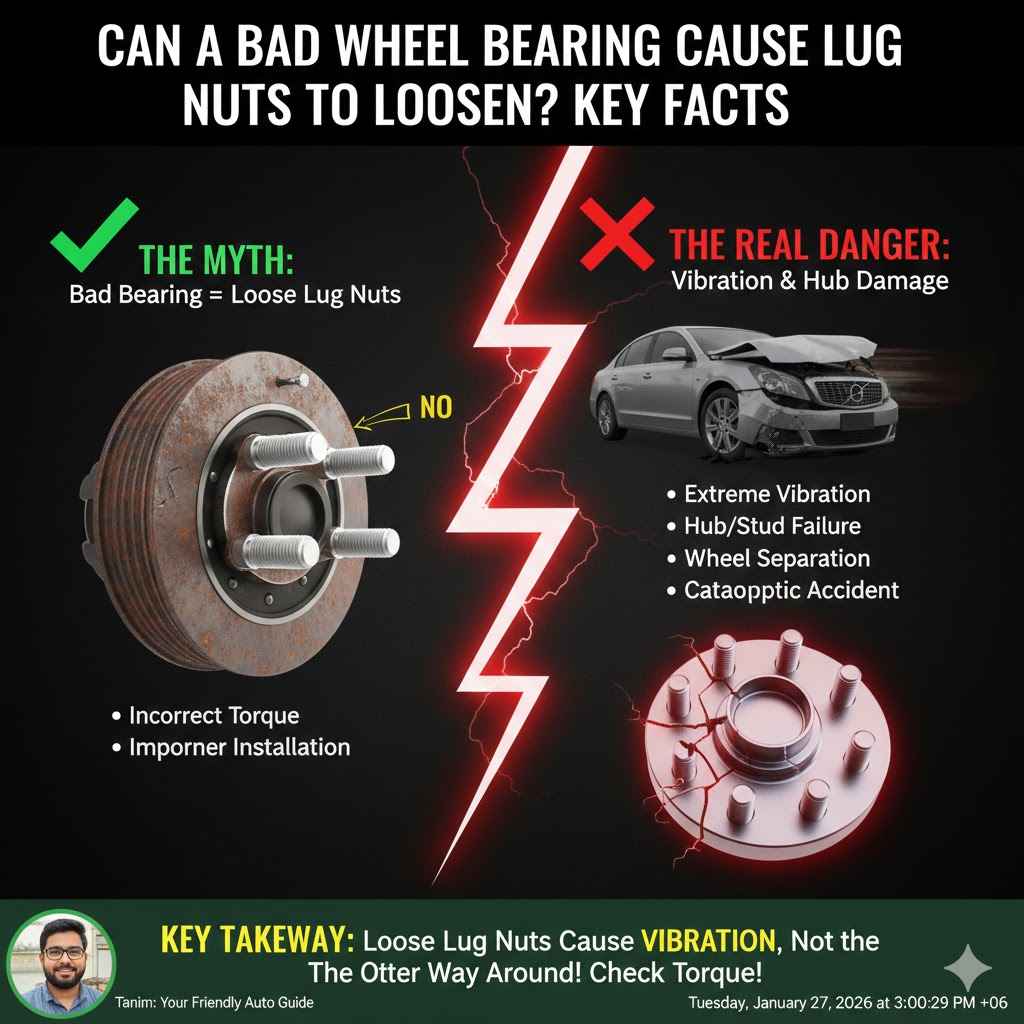

Yes, a bad wheel bearing can absolutely cause lug nuts to loosen. The intense vibration and wobbling from a failing bearing create forces that can overcome the torque holding the lug nuts tight. This is a critical safety hazard that requires immediate attention to prevent a wheel from separating from your vehicle while driving.

Hearing a strange noise from your car can be worrying. You might hear a grinding sound or feel a new vibration through the steering wheel. One of the scariest thoughts is, “Is my wheel about to fall off?” It’s a valid concern, and sometimes, a small problem can lead to a big one. One common question drivers ask is about the connection between a wheel bearing and the lug nuts that hold the wheel in place. In this guide, we’ll break down exactly how these parts are related. You will learn the signs to look for and the simple, safe steps you can take to check your car. Let’s get you back on the road with confidence.

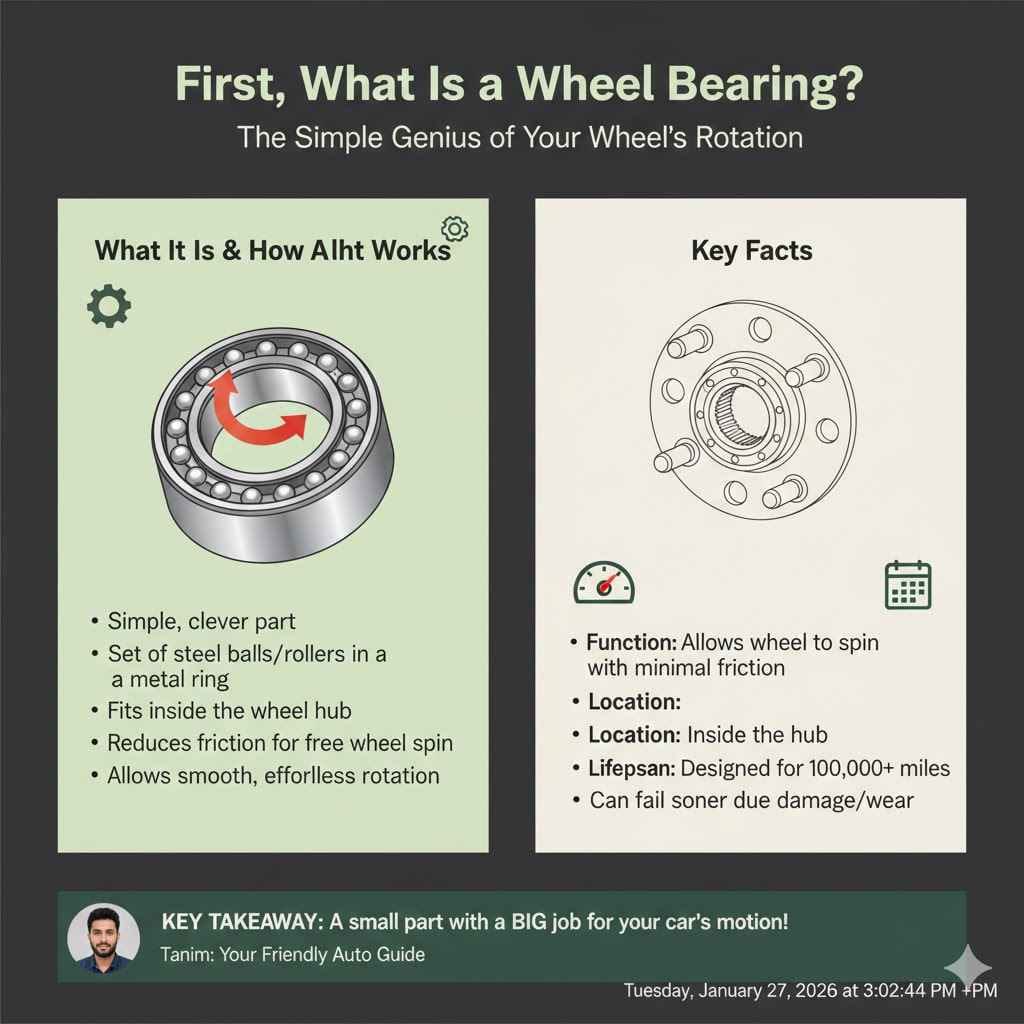

First, What Is a Wheel Bearing?

Think of a wheel bearing as a simple, clever part that lets your wheels spin freely. It’s a set of small, strong steel balls or rollers held together in a metal ring. This assembly fits snugly inside the wheel hub, which is the part your wheel bolts onto.

The main job of a wheel bearing is to reduce friction. Without it, the metal of the wheel hub would grind directly against the metal of the axle. This would create a massive amount of heat and friction, and your wheel wouldn’t be able to spin for long. The bearings allow for a smooth, effortless rotation, mile after mile.

- Function: Allows your wheel to spin with minimal friction.

- Location: Inside the wheel hub, where the wheel attaches to the car.

- Lifespan: They are designed to last a long time, often over 100,000 miles, but can fail sooner due to damage or wear.

And What About Lug Nuts?

Lug nuts are much simpler to understand. They are the heavy-duty nuts that you see on the outside of your wheel. Their one and only job is to hold your wheel securely onto the car’s wheel hub. Your car has several threaded posts, called studs, sticking out from the hub. The wheel slides over these studs, and the lug nuts are threaded on to clamp the wheel tightly in place.

When tightened correctly, they create a powerful clamping force that keeps your wheel from wobbling or, even worse, coming off while you drive. Their importance cannot be overstated—they are a critical safety component.

The Connection: How a Failing Bearing Can Loosen Lug Nuts

Now, let’s connect the dots. A healthy wheel bearing provides a smooth, stable surface for the wheel to rotate around. But when a bearing starts to fail, it introduces chaos into this smooth system. This chaos comes in three main forms: vibration, heat, and wobble.

1. The Destructive Power of Vibration

A failing wheel bearing is no longer smooth. The internal balls or rollers become worn, pitted, or damaged. Instead of gliding, they grind and catch. This creates a constant, high-frequency vibration that travels directly from the hub into the wheel, studs, and lug nuts.

Imagine trying to keep a lid screwed tightly on a jar while it’s in a paint shaker. The constant shaking will eventually work the lid loose. The same principle applies to your lug nuts. The intense vibration from a bad bearing can slowly but surely break the friction that holds the lug nuts in place, causing them to loosen over time.

2. Heat Expansion and Contraction

Friction creates heat. A failing bearing that is grinding instead of rolling generates an enormous amount of heat. This heat transfers to the wheel hub, the wheel studs, and the lug nuts themselves. When metal gets hot, it expands. When it cools down, it contracts.

This cycle of heating up while you drive and cooling down when you park can weaken the connection. As the metals expand and contract at slightly different rates, the clamping force that the lug nuts provide can be reduced. A lug nut that was once perfectly tight might become just slightly less tight after a few heat cycles, making it more vulnerable to loosening from vibrations.

3. The “Wobble” Effect on Clamping Force

The most dangerous effect of a bad bearing is “play” or “wobble.” A worn-out bearing allows the entire wheel and tire assembly to tilt and move erratically. This isn’t just a small vibration; it’s a physical shift of the wheel on the axle.

This wobble puts uneven stress on the wheel studs. Instead of having a consistent, even pressure holding the wheel on, the force is constantly shifting from one stud to another. This flexing and shifting action can physically work the lug nuts loose. It puts immense strain on the threads of both the nuts and the studs, accelerating wear and increasing the risk of failure.

Warning Signs Your Wheel Bearing Is Failing

Your car will almost always give you warning signs before a wheel bearing fails completely. Learning to recognize these signs is key to catching the problem before it leads to loose lug nuts or worse. Here are the most common symptoms:

- A Humming, Rumbling, or Growling Noise: This is the most common sign. The noise typically starts faint and gets louder as you speed up. It might also change or disappear when you turn the steering wheel one way or the other.

- Vibration in the Steering Wheel: You may feel a slight vibration or shudder in the steering wheel that gets worse with speed. This is caused by the roughness of the failing bearing.

- A Clicking or Snapping Sound: You might hear a sharp clicking sound, especially when turning or making slow, sharp maneuvers.

- Pulling to One Side: A badly worn bearing can create drag on one wheel, causing your vehicle to pull to the left or right.

- Uneven Tire Wear: The wobble from a bad bearing can cause your tire to wear down unevenly and much faster than normal.

It’s important to know that some of these symptoms can be caused by other issues. A table can help you see the differences.

| Symptom | Could It Be a Bad Wheel Bearing? | Other Possible Causes |

|---|---|---|

| Humming/Growling Noise | Yes, very likely. Noise changes with speed but not engine RPM. | Tire noise (cupping/scalloping), differential issue. |

| Steering Wheel Vibration | Yes. A constant vibration felt through the wheel. | Unbalanced tires, bent wheel, alignment problems. |

| Car Pulls to One Side | Yes. The failing bearing creates drag on one wheel. | Poor wheel alignment, uneven tire pressure, a sticking brake caliper. |

| Uneven Tire Wear | Yes. The wobble wears the tire on the inside or outside edge. | Bad alignment, worn suspension parts (ball joints, tie rods). |

How to Safely Check for a Problem

If you suspect a problem, you can perform a couple of simple checks at home to confirm your suspicions. Safety is the number one priority here, so always follow these steps carefully.

Safety First: Before You Start

- Park your car on a flat, level surface like a garage floor or a flat driveway. Never work on a slope.

- Engage the parking brake firmly.

- Place wheel chocks behind the wheels on the opposite end of the car from where you will be jacking. For example, if you’re lifting the front right wheel, chock the rear wheels.

Step 1: The Lug Nut Check

This is the easiest check. You don’t even need to lift the car. All you need is the lug wrench that came with your vehicle (it’s usually with the spare tire).

- With the car on the ground, take your lug wrench and place it on each lug nut.

- Try to tighten it gently. The nut should be snug and not move.

- If a lug nut turns with little effort, it is loose. Tighten it until it is snug. Repeat for all lug nuts on all wheels.

Note: “Snug” is a temporary fix. For proper safety, lug nuts should be tightened to a specific “torque” setting using a torque wrench. If you find loose nuts, it’s a sign you need to investigate the cause further.

Step 2: The Wheel Bearing “Wiggle Test”

This test will tell you if the bearing itself is worn out. You will need to lift the wheel off the ground.

- Find the correct jacking point for your vehicle. Consult your owner’s manual if you are unsure. Using the wrong point can damage your car. For great tips on vehicle lift safety, you can check resources like the Canadian Centre for Occupational Health and Safety.

- Place your jack on the jacking point and lift the car until the tire is completely off the ground.

- Place a jack stand securely under the vehicle’s frame or a designated support point as a backup safety measure. Never rely on a jack alone to hold the vehicle.

- Grab the tire with your hands at the 12 o’clock and 6 o’clock positions.

- Try to push and pull the wheel, wiggling it in and out. A good wheel bearing will have no movement at all. If you feel any play, movement, or hear a “clunking” sound, the wheel bearing is bad and needs to be replaced.

- For good measure, move your hands to the 3 o’clock and 9 o’clock positions and repeat the wiggle test.

What to Do If You Discover a Problem

Finding a loose lug nut or a wobbly wheel can be alarming, but acting quickly and correctly is what matters. Here’s a simple guide on what to do next.

If Your Lug Nuts Are Loose

If you find loose lug nuts but the wheel feels solid during the wiggle test, the first step is to tighten them. However, you must find out why they were loose. Was your wheel recently removed for service? Sometimes they are not tightened correctly. Tighten all the nuts, drive a short distance (a few miles), and check them again. If they have loosened again, you almost certainly have an underlying issue like a bad wheel bearing causing vibrations.

If You Suspect a Bad Wheel Bearing

If your wheel fails the wiggle test or you are hearing a loud grinding noise, you should not drive the car if it can be avoided. A bad wheel bearing puts immense stress on the hub and suspension. Continuing to drive increases the risk of the bearing seizing up completely or, in a worst-case scenario, the hub failing and the wheel separating from the vehicle.

Replacing a wheel bearing is generally not a beginner-friendly DIY job. It often requires special tools like a hydraulic press to remove the old bearing and install the new one. This is a job best left to a qualified mechanic.

| Task | Recommended for DIY? | Reason |

|---|---|---|

| Checking Lug Nut Tightness | Yes | Requires only a basic lug wrench and is a simple safety check. |

| The “Wiggle Test” | Yes | Requires safe use of a jack and jack stands but is a straightforward diagnostic test. |

| Replacing a Wheel Bearing | No | This is an advanced repair requiring specialized tools (like a shop press) and technical knowledge to ensure safety and proper installation. |

Frequently Asked Questions (FAQ)

1. Can I just tighten my lug nuts and keep driving if they were loose?

You can tighten them as a temporary measure to get to a safe location or a repair shop. However, you must figure out why they were loose. If a bad wheel bearing is the cause, they will just loosen again. It is not a permanent solution and is unsafe for long-term driving.

2. How much does it cost to replace a wheel bearing?

The cost can vary widely depending on your vehicle’s make and model and local labor rates. Generally, you can expect to pay anywhere from $250 to $700 per wheel. Some vehicles have hub assemblies that are more expensive but easier to install, while others have press-in bearings that are cheaper for the part but require more labor.

3. How long can I drive on a bad wheel bearing?

This is not recommended. While some people might drive for weeks or even months with a noisy bearing, the risk increases every day. The bearing could seize up, causing you to lose control, or the wobble could cause the hub to fail. The safest answer is to get it fixed as soon as you diagnose the problem.

4. What does a bad wheel bearing sound like?

The most common sound is a low-pitched humming, rumbling, or growling that gets louder with vehicle speed. It’s often compared to the sound of driving on a rumble strip or having loud, knobby off-road tires. It’s distinct from engine noise because it changes with wheel speed, not engine RPM.

5. Will a bad wheel bearing turn on my Check Engine Light?

No, a standard wheel bearing failure will not trigger the Check Engine Light. However, on some modern vehicles, a failing wheel bearing can damage the wheel speed sensor, which is part of the Anti-lock Braking System (ABS). If this sensor is damaged, it will turn on your ABS warning light, and possibly the traction control light.

6. Can hitting a big pothole damage my wheel bearing?

Yes, absolutely. A sharp, hard impact from a pothole, curb, or accident can damage the delicate, hardened surfaces inside the bearing. This damage can cause the bearing to fail prematurely, sometimes weeks or months after the impact.

7. Are front and rear wheel bearings different?

Yes, they are often different. Front wheel bearings on front-wheel-drive cars are part of the drive axle assembly and are typically more complex. Rear bearings can be simpler, especially on vehicles with solid rear axles. They are not interchangeable, and each is specific to its location on the vehicle.

Your Safety Comes First

So, can a bad wheel bearing cause lug nuts to loosen? The answer is a clear and definite yes. The vibrations and wobble it creates are more than enough to compromise one of your car’s most important safety systems. Listening to your car is one of the best skills a driver can have. Those new noises and vibrations are your car’s way of telling you that something needs attention.

By understanding the link between a simple bearing and the nuts holding your wheel on, you’re already a more informed and safer car owner. Don’t be afraid to perform the simple checks we discussed. Catching a problem early not only saves you from a potentially dangerous situation but can also save you money on more extensive repairs down the road. Stay safe, stay aware, and drive with confidence.