The brake line helps the caliper apply pressure to the brake pads so they press against the rotors. It ensures the smooth functioning of the brake system. It can be risky when the brake line doesn’t seal with the caliper. Dont worry!! You can fix the issue if you know how to troubleshoot it.

Worn seals and dirt or debris on pads or brake components are the most common causes. You can get a quick solution after replacing the worn seals and removing dirt or debris. However, serious issues, such as over-tightening or improper fittings and damaged threads, can also be the culprit.

I will go into detail about brake line issues in this tutorial, including how to diagnose and resolve them when there is no seal on the caliper.

Symptoms of a Brake Line that Won’t Seal to Caliper

The following are typical indicators that your brake line’s caliper seal is not working properly.

- Noticeable puddles or spots of brake fluid beneath the caliper.

- Reduced brake pedal resistance and a spongy feel when pressed.

- The vehicle may pull to one side during braking due to uneven pressure.

- Illumination of the brake warning light on the dashboard.

- Longer stopping distances and decreased overall braking efficiency.

- Audible signs of metal-on-metal contact or friction during braking.

It may help you fix Ford Integrated trailer brake controller issues: Ford Integrated trailer brake controller problems

Causes of Brake Line Won’t Seal to Caliper

When you are experiencing the brake line won’t seal to the caliper, check for the problems below. It may help you to fix the issue quickly.

- Damaged Threads

- Improper Fitting

- Dirt and Debris

- Over-tightening

- Worn Seals

Brake Line Won’t Seal to Caliper[ Problems & Solutions]

Problem 1: Damaged Threads

Damaged threads on brake lines prevent proper sealing with the caliper, leading to fluid leaks and compromised braking. The threads ensure a tight connection; any damage can disrupt this, risking brake failure. Regular inspection and maintenance are essential to avoid safety hazards.

Solution:

- Lift the vehicle on the Jack and remove its wheel.

- Then, locate the brake caliper; in most passenger vehicles, it is mounted on the front portion over the disc.

- Check the threads on the caliper mounting bolts.

- If you see the threads are damaged, take a thread chaser and clean the threads. I recommend OTC Tools 7402 Universal Outside Thread Chaser for this purpose.

- After that, replace bolts if threads are severely damaged.

- Reinstall the caliper and wheel.

- Test the brake system for proper sealing.

If you have time must read this to solve brake controller issues: 2012 Dodge Ram trailer brake controller problems

Problem 2: Improper Fitting

When brake lines do not seal to the caliper due to improper fitting, it can cause the brake line to not seal to the caliper. It happens due to mismatched sizes, damaged threads, or insufficient tightening. It risks brake failure, produces leaks, and lowers the pressure of the brake fluid.

Solution:

- Safely lift the vehicle on a jack stand. You can use either of the jack stands. However, for better safety, I recommend Pro-Lift 4 Ton Jack Stands.

- Now remove the wheel, exposing the brake system.

- Check the caliper for leaks or visible damage.

- Thoroughly check the brake line for kinks, leaks, or improper fittings.

- Inspect fittings at both ends of the brake line for tightness and proper alignment.

- Ensure the brake fluid level is correct. If low, refill it using a compatible brake fluid.

- If improper fittings are found, reattach or replace fittings and tighten them securely.

- Reassemble and test the brakes for proper sealing.

Problem 3: Dirt and Debris

Dirt and debris prevent a proper seal between the brake line and the caliper. The contaminants disrupt the connection, compromising braking efficiency and safety. Regular cleaning and maintenance are crucial to ensuring a secure and functional seal in the braking system. Check for dirt and debris and provide cleaning to remove the issue.

Solution:

- Raise your vehicle on Jack Stands safely.

- After that, remove the wheel, exposing the brake assembly.

- Now, check the brake caliper for visible dirt or debris.

- Also, check the brake pads and rotor.

- Clean the caliper, pads, and rotor using a brake cleaner.

- Also, examine the caliper slide pins for obstruction.

- Reassemble the brake components.

- Take a test drive to confirm the issue is resolved.

Are you facing issues in pressure building while bleeding the brakes? Here is the solution for you: Cant build pressure when bleeding brakes

Problem 4: Over-Tightening

Over-tightening brake line fittings can damage their shape. It may cause improper sealing of the caliper. Excessive force can damage the threads and crush the sealing surface. It may cause leaks and compromise brake performance.

Solution:

- After lifting your car, locate the brake lines running from the master cylinder to the caliper.

- Then, check the brake line fittings for physical damage.

- There is the possibility of threads due to over-tightening. Check for the threads on pads or brake line fittings. If threads are found, clean them using thread cleaner.

- Also, check the sealing surface for damage.

- Gently loosen the fittings, inspect the fittings, and if they are broken, replace them.

- Reconnect the brake line, ensuring proper alignment, and test the brake system for leaks.

Problem 5: Worn Seals

Worn seals compromise the brake system by allowing fluid leaks between the brake line and the caliper. It can affect the hydraulic pressure. Over time, it may reduce braking efficiency and cause brake failure.

Solution:

- Locate the brake calipers and follow the brake lines to locate fittings.

- Inspect each fitting for signs of wear, corrosion, or leaks.

- After that, clean the fittings with brake cleaner for better visibility.

- For better visibility, use a flashlight to examine closely, focusing on the caliper connections.

- Replace any worn or damaged seals or fittings.

- After repairing, bleed the brakes.

- Lower your vehicle and test the brakes for proper sealing.

How to Replace Brake Caliper Seals?

Follow the steps below to replace the brake caliper seals.

- Lift the car and remove the wheel.

- Loosen the brake line and remove the caliper bolts.

- Take off the old caliper and detach the brake pads.

- Extract the piston and old seals.

- Clean the caliper and piston.

- Install new seals.

- Lubricate the seals and pistons.

- Reassemble the caliper and pads.

- Tighten the bolts and brake line.

- Bleed the brake system.

Can a Brake Line Cause a Caliper to Stick?

Yes, a brake line, if it has fluid blockage or pressure issues, can cause a caliper to stick. Check the brake line for kink damage and its proper lubrication. By solving these issues, you can ensure a smooth brake operation.

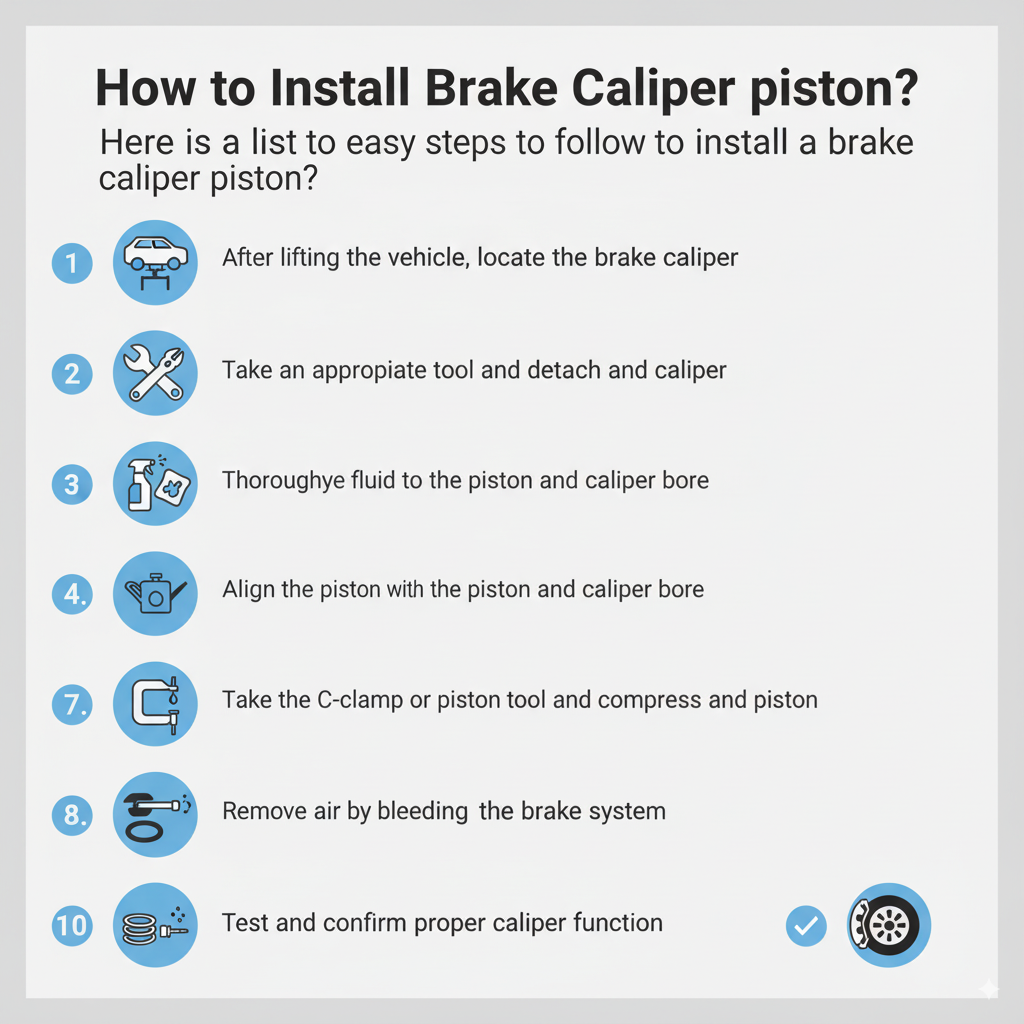

How to Install Brake Caliper Piston?

Here is a list of easy steps to follow to install a brake caliper piston.

- After lifting the vehicle, locate the brake caliper.

- Take an appropriate tool and detach the caliper.

- Thoroughly clean caliper and piston.

- Apply brake fluid to the piston and caliper bore.

- Then align the piston with the caliper bore.

- Take a C-clamp or piston tool and compress the piston.

- After that, place new seals and boots.

- Next, secure the caliper back onto the bracket.

- Now, remove air by bleeding the brake system.

- Test and confirm proper caliper function.

Frequently Asked Questions (FAQs):

Can old brake lines cause caliper to stick?

Yes, it is feasible since older brake lines might have more corrosion or dirt in them, which could harm the lines or cause improper fluid flow. The caliper sticking may be caused by a problem with broken lines or an incorrect flow.

Will air in brake lines cause caliper to stick?

The air in the brake lines can create sponginess, which may cause the caliper to stick. Due to swelling, the pressure distribution becomes uneven, which may prevent the pistons from retracting properly.

Why is my brake line leaking at the caliper?

It can be due to many problems; however, the primary reasons include worn-out brake lines or loose connections. You may also experience that issue due to damage to the caliper itself. Check for the line, connections, and caliper and replace or repair the items that are needed.

Where do brake calipers leak from?

You may experience a brake caliper leak from the piston boots or damaged seals. It can reduce braking efficiency and requires quick fixation. It needs regular maintenance to maintain its braking efficiency.

Conclusion

Your braking system’s performance may worsen when the brake line doesn’t seal to the caliper. It happens due to multiple issues with the brake system or its components. First, find out the major problem, and then fix the issue following the above guidelines. However, if you are not confident in your skills, avoid it.