Quick Summary: For most drivers, high-performance carbon fiber wheels are an upgrade reserved for track use or major modifications. While they offer excellent weight reduction and stiffness for elite performance gains, the high cost and potential fragility for daily driving often mean standard aluminum alloy wheels remain the smarter, cost-effective choice for everyday reliability and budget.

Upgrading your car’s wheels seems like a fun way to boost looks and speed. You hear whispers about carbon fiber—light, strong, and used for race cars. But is this high-tech stuff really worth the big price tag when you are just driving around town? It can be confusing to figure out what makes one wheel better than another. Are we talking about a tiny performance bump, or something you can truly feel every day?

Don’t worry! We are going to break down exactly what carbon wheels offer, who needs them, and why your trusty aluminum set might be just fine. Think of me as your trusted guide, simplifying the science so you can make a confident, smart choice for your ride. Let’s explore the real-world gains of going carbon!

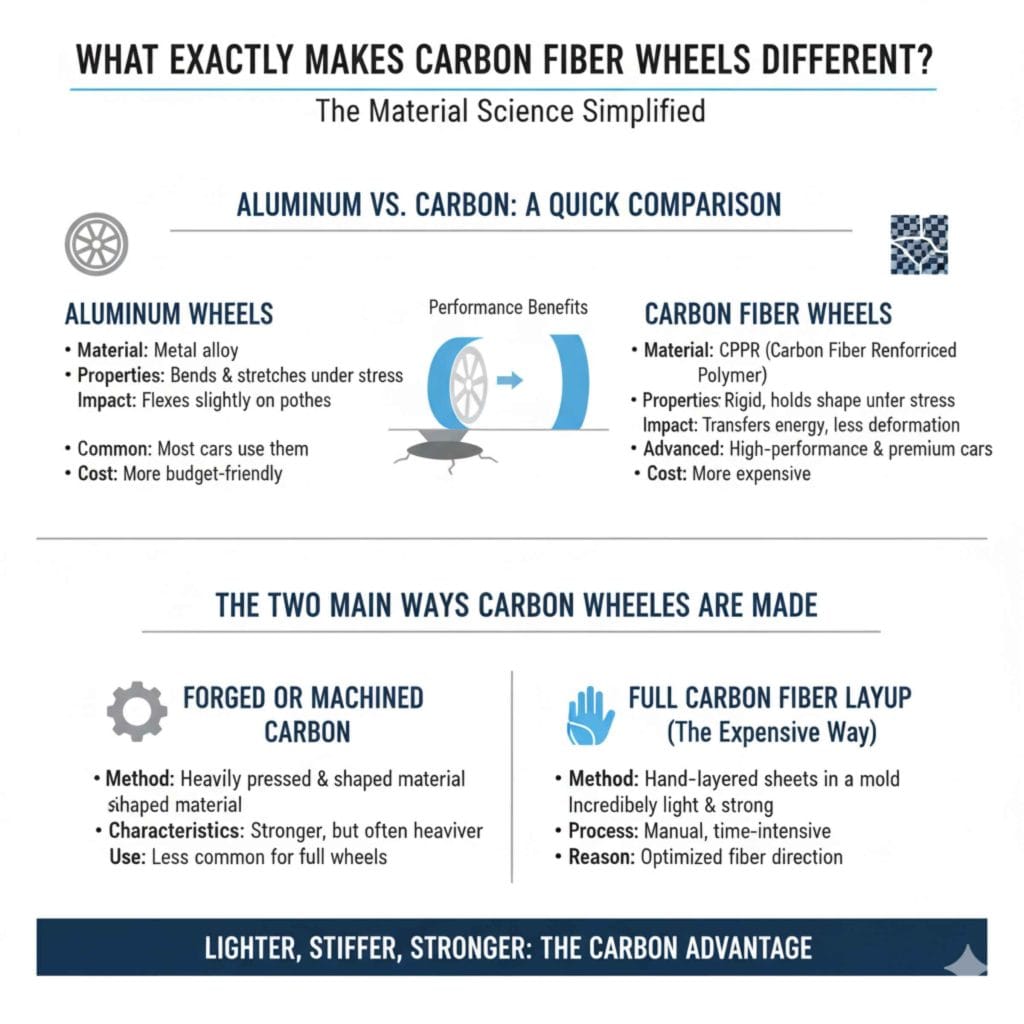

What Exactly Makes Carbon Fiber Wheels Different? The Material Science Simplified

When you look at a wheel, you see metal. Most cars today, even nice ones, roll on aluminum alloy wheels. They are a great blend of strength, light weight, and cost. Carbon fiber wheels, however, use a completely different material—carbon fiber reinforced polymer (CFRP).

Imagine weaving incredibly thin, strong threads of carbon, then hardening them with a tough plastic resin. This results in a material that is amazingly light yet incredibly stiff. This stiffness is key to performance, but let’s see how that plays out on the road.

Aluminum vs. Carbon: A Quick Strength Comparison

To understand the fuss, we need to compare what they are made of. Aluminum is a metal that bends and stretches a bit under stress. Carbon fiber is a composite material that is designed to be rigid and handle forces without deforming much. This difference in material leads directly to the performance benefits we often read about.

Think about swinging a hammer. An aluminum wheel might flex slightly when hitting a big pothole. A carbon wheel tries to hold its shape perfectly, transferring that energy directly to the road or the suspension system.

The Two Main Ways Carbon Wheels Are Made

Not all carbon wheels are built the same way. Understanding the construction helps explain the cost and durability differences. For beginners, just know there are two primary methods:

- Forged or Machined Carbon: This is less common for full carbon wheels but involves using carbon material that is heavily pressed and then shaped. It’s strong but often heavier than the second method.

- Full Carbon Fiber Layup (The Expensive Way): This is the holy grail of carbon wheels. Technicians carefully layer hundreds of sheets of carbon fiber cloth by hand in a mold. This process optimizes the fiber direction exactly where the wheel needs the most strength, making it incredibly light and strong simultaneously. This manual, time-intensive process is why these wheels cost so much.

Essential Gain #1: Significant Weight Reduction (The Biggest Selling Point)

If you ask any performance enthusiast why they want carbon wheels, they will instantly say, “Weight savings!” This isn’t just about having less weight on the car; it’s about where that weight is located—the wheel.

Understanding Unsprung Weight

This is one of the most important terms to grasp. “Unsprung weight” is everything on your car that is not supported by the suspension. This includes your wheels, tires, brakes, and hubs. “Sprung weight” is everything supported by the springs, like the chassis and engine.

Reducing unsprung weight is far more effective than reducing sprung weight. Why?

- Suspension Works Better: When wheels are lighter, your suspension system (shocks and springs) can react much faster to bumps and road imperfections. This means the tire stays in contact with the road more consistently.

- Quicker Acceleration and Braking: A lighter wheel has less rotational mass. It takes less energy (horsepower) to spin it up to speed, and it takes less braking force to slow it down.

How Much Lighter Are We Talking?

This difference can be shocking, especially when comparing high-end forged aluminum to high-end carbon.

| Wheel Type | Approximate Weight Per Wheel (19-inch Standard) | Weight Savings Compared to Standard Alloy (Typical) |

|---|---|---|

| Standard Factory Alloy | 28 – 32 lbs | N/A |

| High-Quality Forged Aluminum | 22 – 25 lbs | Up to 7 lbs saved |

| High-Quality Carbon Fiber | 16 – 18 lbs | Up to 14 lbs saved (Over factory standard) |

That 14-pound total saving (four wheels) might not sound like much on a 3,500-pound car, but remember its location! This reduction in rotational inertia can sometimes be felt as equivalent to removing 50 to 100 pounds from the car’s main body when accelerating.

Essential Gain #2: Increased Stiffness and Handling Precision

Stiffness relates to how much a wheel bends or flexes when a strong force pushes on it, like during hard cornering or heavy braking. Carbon fiber is inherently much stiffer than aluminum.

Cornering Confidence

When you take a sharp corner quickly, the forces push sideways on your wheels. Aluminum wheels flex slightly under this load. This flexing means the tire treads aren’t perfectly planted on the pavement, leading to a slight delay or “mushiness” in steering response.

Carbon wheels hold their shape almost perfectly. This precision means the tire reacts immediately to your steering input. For track driving, this translates into faster lap times and better driver feedback. For daily driving, it means the car feels more responsive and “planted.”

Braking Performance

When you slam on the brakes, the heat generated is massive. Wheels help dissipate this heat. While aluminum is known for good heat transfer, the rigidity of carbon wheels means they manage the mechanical stresses of braking better. They resist the immense torsional forces without losing integrity, which is vital when every fraction of a second counts.

For more technical details on how wheel material affects suspension dynamics, you can explore reputable engineering resources on rotational dynamics, such as those found in university research archives regarding vehicle dynamics.

Essential Gain #3: Aerodynamic Benefits (The Subtle Edge)

This area is where modern wheel design gets really clever. Weight loss is easy to measure, but aerodynamics—how the wheel cuts through the air—is often overlooked but crucial at higher speeds.

How Wheel Shape Matters

Wheels are essentially spinning buckets. They churn up air, creating drag (resistance). This drag wastes fuel and robs power.

- Aluminum Wheels: Traditional multi-spoke alloy designs often create significant turbulence.

- Carbon Wheels: Because carbon manufacturing is so flexible (molding), designers can create very specific, often flatter or more closed spoke patterns that actively reduce air turbulence.

This aerodynamic advantage is subtle at low city speeds (under 40 mph). However, on the highway, where aerodynamic drag becomes the main force resisting your car, these smoother, lighter wheels require less power to maintain speed, leading to very minor but measurable improvements in fuel efficiency or top-end speed.

The Reality Check: When Are Carbon Wheels NOT Worth It For You?

It’s easy to get swept up in the hype around exotic materials. But for the average driver—the commuter, the grocery-getter, the weekend cruiser—the answer to “are carbon wheels worth it?” is overwhelmingly “no.”

Here are the main reasons the average driver should stick to high-quality aluminum:

1. The Astronomical Cost

This is the biggest barrier. A set of premium, forged aluminum wheels might cost between $3,000 and $5,000. A comparable set of top-tier carbon fiber wheels (like those made by companies specializing in this) can easily start at $8,000 and climb well past $12,000.

If you are spending that much money, ask yourself: Could I buy a fantastic, high-quality suspension setup (shocks and springs) for that same price? Most often, a superior suspension upgrade will provide a more noticeable, usable performance and comfort improvement in daily driving than expensive wheels.

2. Durability and Repair Compared to Aluminum

Aluminum is tough. When an aluminum wheel hits a massive pothole, it often bends or cracks in a visible way. While it still requires professional repair (or replacement), it usually gives you a warning sign.

Carbon fiber is different. Because of how the composite fibers are layered, they can sometimes fail catastrophically or sustain internal damage without any visible external crack—especially from sharp impacts like curbs or deep potholes. While carbon is stronger in flexing scenarios, it can be more brittle against sharp, sudden point loads.

If a carbon wheel is damaged, the repair process is extremely specialized, costly, and requires sending the wheel back to experts who can inspect the internal structure. Many garages cannot simply “straighten” a carbon wheel like they can an alloy one.

3. Tire Fitment and Maintenance Concerns

Mounting and balancing high-performance tires on carbon wheels requires careful handling. Technicians who are not specifically trained on carbon layup procedures might inadvertently damage the rim during tire mounting or using standard impact guns. Always ensure your shop knows how to handle these delicate structures.

Furthermore, road grime, brake dust, and cleaning chemicals must be chosen carefully to protect the clear coat and the carbon matrix underneath.

Who Should Actually Consider Buying Carbon Fiber Wheels?

If you fall into one of these categories, the high cost starts to become justifiable because the gains directly impact the vehicle’s primary use.

- Serious Track Enthusiasts and Racers: Where shaving tenths of a second off a lap time is the goal, every ounce saved and every bit of stiffness gained adds up to real results.

- High-End Supercar/Hypercar Owners: For cars costing hundreds of thousands of dollars, the extra expense of carbon wheels is a fraction of the total cost, and they are essential for achieving the manufacturer’s ultimate performance targets.

- Extreme Weight Reduction Projects: If the vehicle is being built specifically for competitive drag racing or hill climbs where weight is the absolute enemy, carbon wheels provide the maximum possible rotational weight savings.

A Practical Guide: How to Gain Wheel Performance Without Carbon Costs

If you want better handling and quicker response without emptying your savings account on carbon fiber, focus your budget on smarter, less exotic upgrades:

Step 1: Upgrade to Quality Forged or Flow-Formed Aluminum

Flow-formed (or rotary forged) aluminum wheels are the sweet spot for most enthusiasts. This manufacturing process takes a standard cast wheel blank and spins and presses it under heat, making the barrel of the wheel much stronger and lighter than a simple cast piece, without the carbon fiber price tag.

These wheels offer noticeable weight reduction over stock alloy wheels and excellent durability for daily use.

Step 2: Invest in Better Tires

This might be the single best performance upgrade you can make. A set of high-performance summer tires will dramatically improve grip, braking distance, and steering feel. Tires are the only part of your car touching the road, so their quality matters more than almost anything else.

Step 3: Focus on Suspension Components First

As mentioned earlier, upgrading your shocks and springs (coilovers, for example) will allow your existing wheels to work more efficiently by keeping them pressed firmly against the road surface, regardless of bumps.

| Upgrade Path | Primary Benefit | Cost vs. Benefit (Daily Driver) |

|---|---|---|

| Carbon Fiber Wheels | Maximum weight reduction, high stiffness | Very High Cost, Low Usable Gain |

| Flow-Formed Aluminum Wheels | Good weight reduction, great durability | Medium Cost, Good Usable Gain |

| High-Performance Tires | Maximum grip and braking | Low to Medium Cost, Highest Usable Gain |

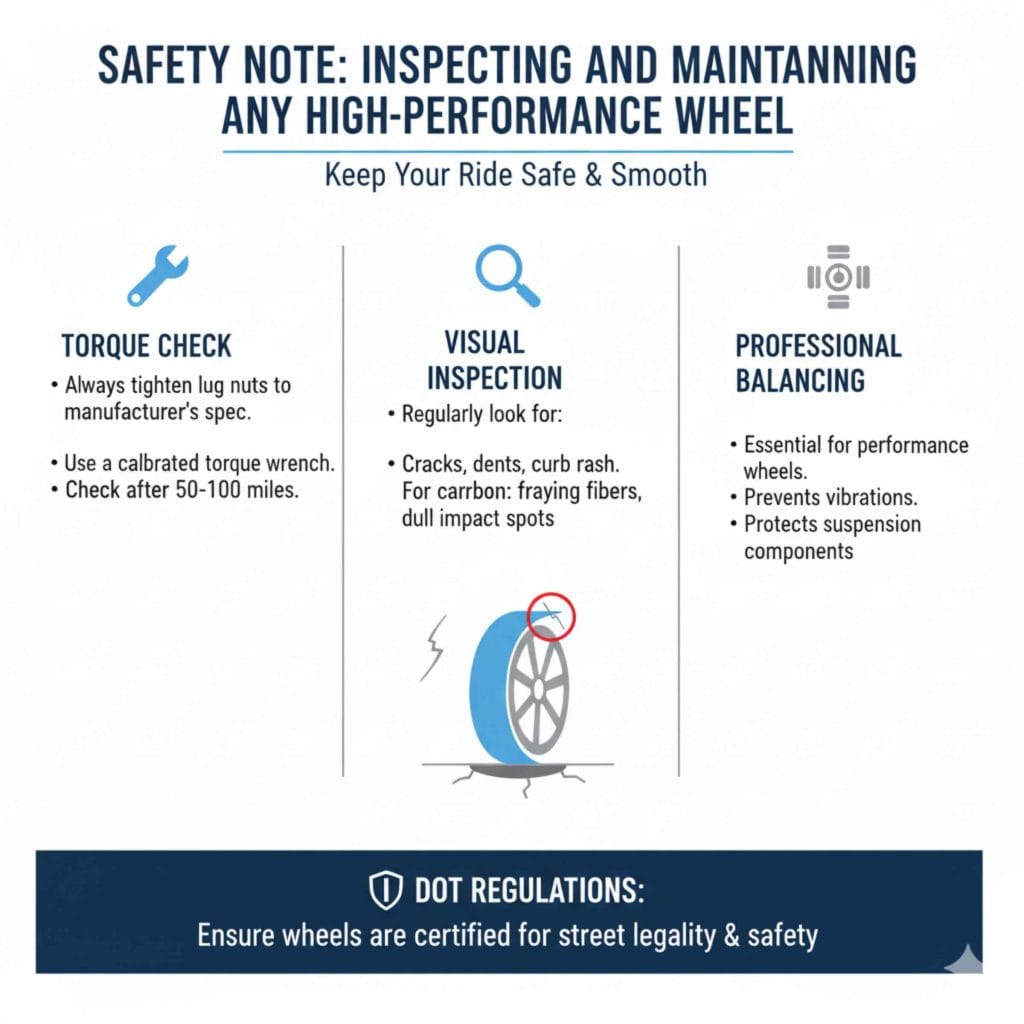

Safety Note: Inspecting and Maintaining Any High-Performance Wheel

Whether you choose shiny aluminum or exotic carbon, proper maintenance is essential to safety. Loose lug nuts are dangerous for any wheel, but they can be catastrophic for complex structures like carbon rims.

Here are quick, mandatory safety steps:

- Torque Check: Always tighten your lug nuts to the manufacturer’s specified torque setting using a calibrated torque wrench. Do this when first installing them, and then check them again after 50–100 miles of driving.

- Visual Inspection: Regularly look for cracks, dents, or significant curb rash. For carbon, look closely for fraying fibers or dull spots that indicate impact damage.

- Professional Balancing: Always have performance wheels balanced by a shop with the necessary weights and equipment. Poor balancing causes vibrations that can damage suspension components over time.

Remember, the United States Department of Transportation (DOT) regulations require all vehicle components, including wheels, to meet stringent safety criteria. Always ensure any aftermarket wheel you purchase is certified to meet or exceed these standards for street legality and safety.

Frequently Asked Questions (FAQ) About Carbon Wheels

Q1: Are carbon fiber wheels street legal for everyday driving?

A: Yes, generally they are street legal if they meet the required DOT safety standards (and the standards of your local jurisdiction). However, their high cost and potential vulnerability to impacts mean they are often overkill for regular street use.

Q2: Do carbon wheels really improve fuel economy?

A: They offer a very slight improvement. Because they reduce rotational mass and often have better aerodynamic shapes, they slightly decrease the energy needed to maintain speed. However, the improvement is usually too small to notice compared to just driving slightly slower.

Q3: How fast can I drive on carbon wheels in the rain?

A: Your speed limits in the rain are determined by your tires and your ability to see, not your wheels. However, the better grip from reduced unsprung weight can slightly improve stability, but always reduce speed significantly when roads are wet.

Q4: Can I use the same tires on carbon wheels as my old alloy wheels?

A: Yes, as long as the diameter (e.g., 18-inch) and width measurements match exactly for the intended vehicle. The tire just needs to fit the bead seat correctly.

Q5: Is buying used carbon wheels a good idea?

A: This is risky for a beginner. Because hidden damage is hard to spot, buying used carbon wheels without a full inspection from the original manufacturer or a specialized composite shop is generally not recommended for safety-critical components.

Q6: How loud are carbon wheels compared to aluminum?

A: Wheels themselves do not create road noise; the tires do. However, if the stiff carbon structure transmits more vibration into the chassis, you might perceive slightly more noise, though this is usually negligible compared to loud performance tires.

Conclusion: Making the Confident Choice For Your Car

So, are carbon wheels worth it? For the daily driver prioritizing reliability, cost-effectiveness, and ease of maintenance, the answer is almost certainly no. High-quality aluminum alloy wheels offer 90% of the usable, everyday benefit with 50% of the cost and vastly superior durability against unexpected road hazards.

The essential gains of carbon wheels—extreme weight saving and hyper-stiffness—are real, proven, and undeniable. But these gains only translate into noticeable, repeatable results when the car is already pushed to its absolute limits, such as on a race track. Think of carbon wheels as the final, specialized tool for a dedicated racer, not the first upgrade for the everyday commuter.

Take the money you save by sticking to great flow-formed or forged aluminum wheels and put it toward a fantastic set of tires and maybe a good suspension alignment. That combination will give you a massive, reliable boost in driving confidence and enjoyment that you will feel every single day you drive your car. You’ve got this, and making smart, informed choices is the best maintenance you can do!