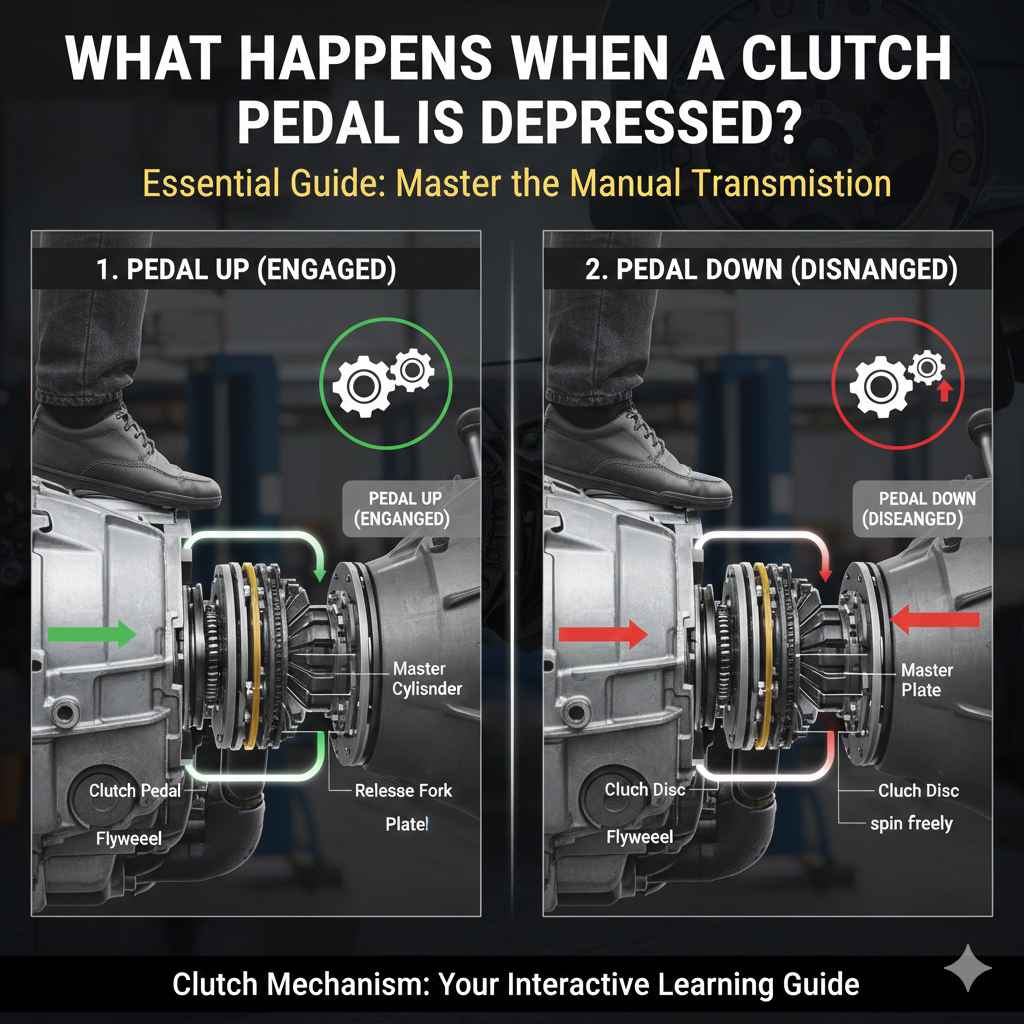

When you press the clutch pedal in a manual car, you are mechanically disconnecting the engine from the transmission. This allows you to shift gears without grinding them by stopping the flow of power, letting the spinning parts synchronize.

Ever felt nervous about driving a stick shift? Understanding what happens under the hood when you touch that third pedal—the clutch—is the key to feeling confident behind the wheel. Many drivers wonder exactly how this magic trick works when they push the clutch pedal down. It seems simple, but a lot of important engineering is happening fast! Don’t worry; we will break down this essential function into easy steps. By the end of this guide, you will know exactly what happens when a clutch pedal is depressed, making your driving smoother and safer.

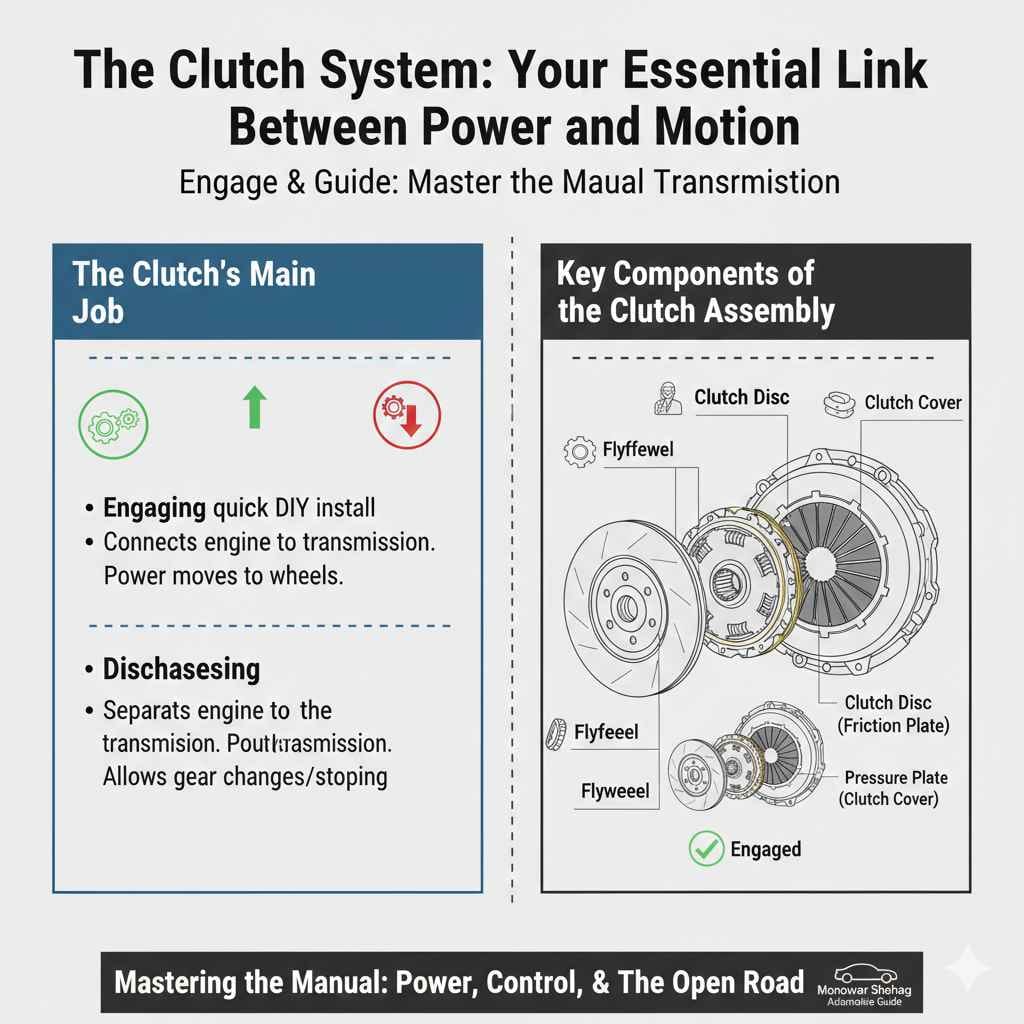

The Clutch System: Your Essential Link Between Power and Motion

Think of your car’s engine as the powerhouse and the wheels as the movers. The clutch system is the on/off switch that lets you manage when the powerhouse gets connected to the movers. Without it, you couldn’t stop the car without stalling the engine every single time you wanted to change speed or direction.

What is the Clutch’s Main Job?

The clutch has two main jobs, and both are critical for a smooth ride:

- Engaging: Connecting the engine firmly to the transmission so that power smoothly moves to the wheels.

- Disengaging (Depressing the Pedal): Temporarily separating the engine from the transmission so you can shift gears or stop without stalling.

Key Components of the Clutch Assembly

To understand what happens when you press the pedal, you need to know the three main players inside the bell housing:

- Flywheel: This is a large, heavy disc bolted directly to the engine. It spins any time the engine is running.

- Clutch Disc (Friction Plate): This sits between the flywheel and the pressure plate. It has friction material, much like brake pads, which grabs the flywheel to transfer power.

- Pressure Plate (Clutch Cover): This component clamps the clutch disc tightly against the flywheel using strong springs. This is the “engaged” state.

Step-by-Step: What Happens When A Clutch Pedal Is Depressed

When you push the clutch pedal down with your left foot, you initiate a chain reaction that temporarily stops power transfer. This sequence is surprisingly fast but follows a very clear mechanical path. This process is what allows you to shift cleanly, whether you are going into first gear or slowing down in fifth.

Step 1: The Pedal Movement

You push the pedal down. This movement travels through a linkage system to the clutch release mechanism. In older cars, this was purely mechanical (cables); in most modern vehicles, it uses hydraulic fluid, similar to your brake system.

Hydraulic vs. Cable Systems

It’s helpful to know which system your car likely uses, as it affects how the pedal feels:

| System Type | Mechanism | Feeling/Action |

|---|---|---|

| Hydraulic Clutch | Master and slave cylinders use brake fluid pressure. | Smooth, consistent pressure, often lighter pedal effort. |

| Cable Clutch | A direct steel cable connects the pedal to the release fork. | More direct mechanical feel, may require more force. |

Step 2: Activating the Release Fork

Once the pedal movement reaches the transmission area, it moves a part called the release fork (or throw-out fork). This fork acts like a lever, pushing a bearing inwards.

Step 3: Engaging the Throw-Out Bearing

The release fork pushes the throw-out bearing (also called the release bearing or pilot bearing). This bearing is the crucial intermediary. It never touches the flywheel directly; it only interacts with the pressure plate.

Step 4: Deactivating the Pressure Plate (The Critical Moment)

This is where the magic happens. The throw-out bearing pushes against the center of the pressure plate assembly. Remember, the pressure plate is what clamps the clutch disc to the flywheel using strong springs.

- When the bearing pushes the center of the pressure plate inward, it physically pivots the pressure plate away from the clutch disc.

- This action releases the clamping force that was holding the clutch disc against the flywheel.

Step 5: Disengagement and Free Spinning

With the clamping force gone, the friction material on the clutch disc is no longer pressed against the spinning flywheel. At this moment:

- The engine is still spinning the flywheel at engine speed.

- The transmission input shaft (which is connected to the clutch disc) is now allowed to slow down or stop spinning relative to the engine speed.

The engine and the transmission are effectively disconnected. You can now move the gear selector freely without damaging the internal gears of the transmission. This state is called “clutch disengaged.”

When You Release the Pedal

When you slowly let the clutch pedal up, the entire process reverses:

- The throw-out bearing moves away from the pressure plate.

- The strong springs in the pressure plate clamp the clutch disc firmly against the flywheel again.

- Friction is restored, and power smoothly transfers from the engine back through the transmission to the wheels.

The speed at which you release the pedal determines how smoothly this re-engagement happens—this is what drivers call finding the “bite point.”

Why Understanding This Matters for Driving Confidence

Knowing the mechanical sequence helps you troubleshoot common driving frustrations and helps you maintain your car better. It demystifies the process, turning a scary manual operation into a logical action-reaction sequence.

Common Driving Mistakes Related to Clutch Use

Many novice drivers make mistakes because they don’t visualize this mechanical disconnect. Here are a few common issues:

- Riding the Clutch: Resting your foot lightly on the pedal while driving. This keeps the throw-out bearing slightly engaged, causing the bearing to constantly press against the pressure plate, leading to premature wear.

- Slamming the Pedal: Releasing the pedal too quickly. This causes the sudden, harsh transfer of power, resulting in a “jerk” or stalling, as the engine speed and wheel speed cannot match up instantly.

- Not Fully Depressing: If you don’t push the pedal all the way down, you don’t fully release the clamping force. This causes “gear grind” because the transmission gears are trying to mesh while still receiving partial power.

External Resources for Further Learning

For drivers interested in the safety and mechanical specifics of vehicle operation, official sources provide excellent, reliable information. For instance, the National Highway Traffic Safety Administration (NHTSA) offers resources on vehicle control systems which are relevant to understanding how pedals affect drivetrain safety.

Troubleshooting: Signs Your Clutch Pedal Action Isn’t Working Right

If pressing the pedal down doesn’t result in the expected smooth disengagement, something in the chain reaction is failing. Since the system relies on movement and sometimes hydraulic pressure, issues are usually easy to spot once you know what to look for.

Symptoms of a Clutch Problem

1. Grinding Gears When Shifting

This almost always means the clutch isn’t fully disengaging. The flywheel is still turning the transmission shaft when you try to engage a gear.

- Possible Cause: Low or leaking hydraulic fluid, a broken clutch cable, or a faulty pressure plate mechanism.

2. Clutch Pedal Sticks to the Floor

If you push the pedal down and it won’t come back up, or it stays on the floor, this is a strong indication of a hydraulic failure.

- Likely Cause: A leak in the master or slave cylinder, meaning the fluid that pushes the bearing cannot build pressure or return properly.

3. Spongy or Loose Pedal Feel

The pedal feels floppy, overly light, or soft, and doesn’t provide firm resistance.

- Likely Cause: Air trapped in the hydraulic line. Air compresses easily, unlike fluid, leading to a weak push on the release fork. This requires bleeding the clutch system.

4. Clutch Chatter or Shuddering When Engaging

This happens when you are releasing the pedal, not depressing it, but it’s related to the connection failure. The car shakes violently as you try to move off from a stop.

- Possible Cause: Glazed or worn-out friction material on the clutch disc, or potentially warped components like the flywheel.

Understanding Wear and Tear Over Time

The clutch is a wear item. Every time you depress the pedal and re-engage the clutch, tiny amounts of the friction material wear away. Over tens of thousands of miles, this material thins out. When the material gets too thin, the pressure plate cannot clamp down hard enough, leading to “slipping”—the engine revs up, but the car doesn’t accelerate proportionally.

This wear is normal, but aggressive driving (lots of hard starts or riding the clutch) shortens its life significantly. A healthy clutch system ensures that the pedal depression action is smooth and effective for the life of the parts.

DIY Checks: Simple Things You Can Check Yourself

You don’t need to be a mechanic to check the basic linkage of your clutch system. These checks boost your confidence in knowing when to seek professional help.

Checking Hydraulic Fluid Levels

If your car uses a hydraulic clutch, the fluid reservoir is often shared with the brake system, or it has its own small, separate reservoir near the firewall under the hood.

- Locate the reservoir (consult your owner’s manual if unsure).

- Check the fluid level against the MIN/MAX marks.

- If low, top it up with the correct type of brake fluid (usually DOT 3 or DOT 4—never mix types!).

Safety Note: Brake fluid can damage paint. Wipe up any spills immediately.

Inspecting the Pedal Linkage (If Applicable)

If you have a cable system or want to look at the pivot point for a hydraulic setup:

- Get a flashlight and look under the dashboard where the pedal arm pivots.

- Ensure the cable or pushrod connecting the pedal to the mechanism is securely attached and is not frayed or broken.

- Check the bushings around the pivot point for excessive looseness.

A loose connection here means your physical foot input isn’t translating fully to the mechanism that pushes the throw-out bearing.

Testing the Engagement Point

This test helps determine if the clutch is wearing out:

- Get the car warmed up and in a safe, empty parking lot.

- Start in first gear with the parking brake firmly set (safety first!).

- Slowly let the clutch pedal up. Note exactly where the car starts to pull forward—this is the “bite point.”

- If the bite point is very high (right near the top of the pedal travel), the clutch disc is likely very thin, and replacement is approaching. If it engages near the floor, the system might be hydraulic and needs bleeding or adjustment.

For more detailed diagnostics, reliable sources like automotive repair manuals often detail specific torque specifications for these components.

Clutch Pedal Depressed: The Quizlet Snapshot for Quick Recall

If you are studying for a driving test or just need a fast reminder before heading to the garage, this summary captures the core process of what happens when you press the clutch pedal.

The Disengagement Sequence in Three Key Actions

| Action Taken By Driver | Mechanism Activated | Result (Power Flow) |

|---|---|---|

| Push Pedal Down | Release fork pushes the throw-out bearing. | The pressure plate releases its clamp. |

| Pedal Fully Down | The clutch disc is physically separated from the flywheel. | Engine is completely disconnected from the transmission. |

| Shift Gear | Gears inside the transmission can now align easily. | Gear change is made without grinding. |

The key takeaway is that depressing the pedal creates a gap where there was pressure, stopping torque transfer so you can change direction inside the gearbox.

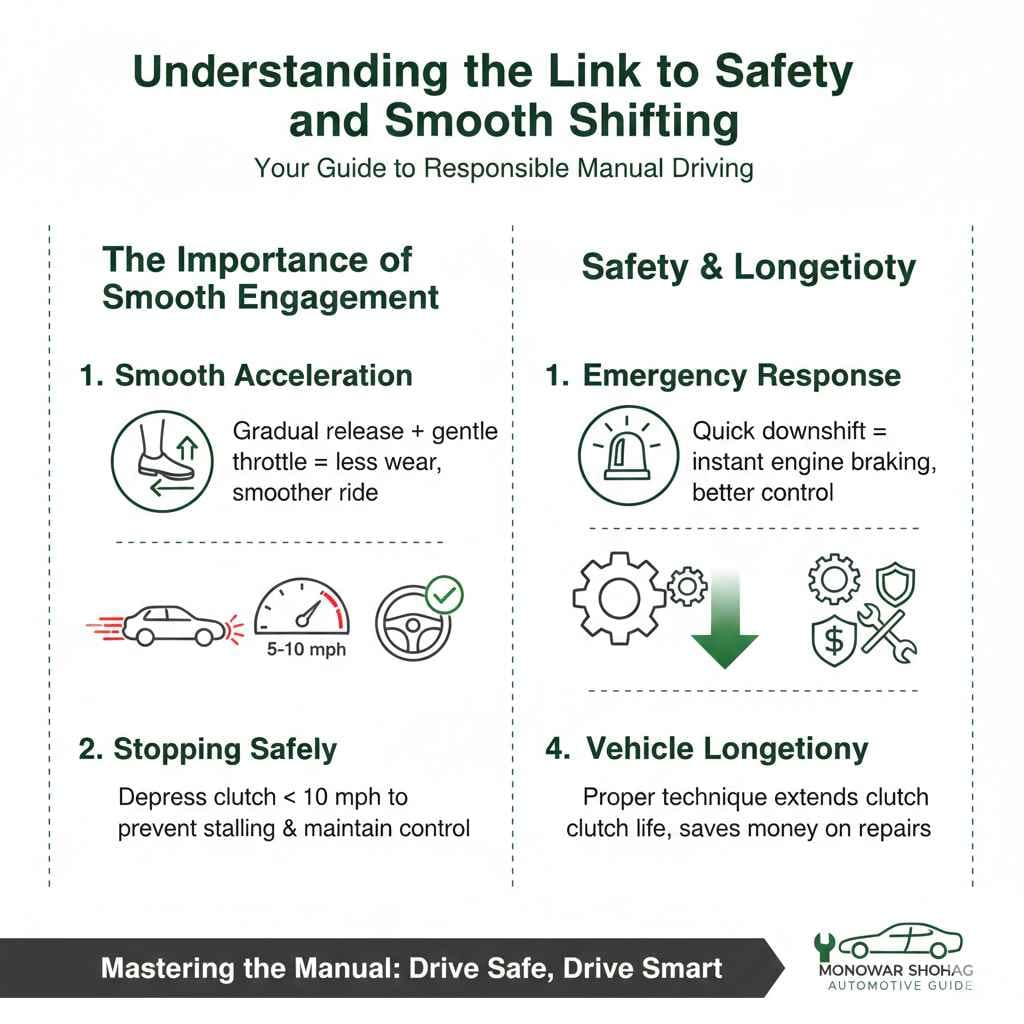

Understanding the Link to Safety and Smooth Shifting

Learning about the clutch isn’t just about passing a written exam; it’s about safety and vehicle longevity. A properly functioning clutch system ensures that when you need to react quickly—like downshifting to slow down in an emergency—that disconnect happens instantly and effectively.

The Importance of Smooth Engagement

While depressing the pedal disconnects the system, releasing it reconnects it. This re-engagement phase is where most wear occurs, and where driver skill is most visible.

- Smooth Acceleration: Gradually increasing engine RPMs while slowly releasing the pedal ensures the friction surfaces meet gently, maximizing clutch life.

- Stopping Safely: When coming to a stop, depressing the clutch pedal before the car drops below 5-10 mph prevents the engine from stalling abruptly, which can affect steering control in tight situations.

Confidence in manual driving comes from respecting this mechanical link. When you understand that the pedal is simply the lever for the throw-out bearing, you gain better control over that power transfer.

Frequently Asked Questions (FAQ) About the Clutch Pedal

Q1: What happens if I press the clutch pedal while driving in a straight line on the highway?

A: If you fully depress the clutch pedal while driving fast, you disconnect the engine from the wheels. The car will coast. The engine RPMs will drop, and the engine will remain running but disconnected from your speed until you release the pedal. This is sometimes done briefly when shifting up through higher gears.

Q2: Do automatic cars have a clutch pedal?

A: No, standard automatic transmissions do not have a clutch pedal. They use a device called a torque converter, which uses fluid coupling to achieve the same effect—connecting and disconnecting the engine from the transmission—but it does so automatically without driver input.

Q3: How do I know if my clutch hydraulic fluid is low?

A: If the fluid is low, you will likely notice the clutch pedal becoming spongy, or you might find spots of brake fluid leaking near the cylinders under the hood or near the firewall. Check your fluid levels regularly, just like your engine oil.

Q4: Is it bad to shift gears without using the clutch pedal (floating gears)?

A: While expert drivers can sometimes “float” gears by matching engine speed perfectly, for beginners, it is highly discouraged. Attempting to shift without depressing the clutch puts immense stress on the internal synchros and gears of the transmission, potentially causing expensive damage.

Q5: What is the “bite point” of the clutch?

A: The bite point is the specific spot in the pedal’s travel (usually toward the top as you release it) where the clutch disc first begins to make contact with the flywheel and starts transferring power. Mastering this point is key to smooth starts.

Q6: Why does my clutch pedal feel stiff all of a sudden?

A: A very stiff pedal usually points to a mechanical failure in the pressure plate springs or a problem with the clutch fork itself. If the hydraulic system fails completely, the pedal often feels too loose, but extreme stiffness suggests a physical binding issue.

Q7: How long should a clutch last before I need to replace the parts?

A: A clutch can last anywhere from 50,000 to 100,000 miles or more. It heavily depends on driving habits. City driving with lots of stopping and starting wears out clutches much faster than highway driving.

Conclusion: Taking Control of Your Manual Transmission

Understanding what happens when a clutch pedal is depressed transforms driving a manual car from a guessing game into a controlled process. When you press that pedal, you are simply operating a powerful lever system designed to temporarily pull the throw-out bearing into the pressure plate, releasing the grip on the spinning flywheel. This separation is instantaneous, giving you the vital moment needed to select a new gear or prepare to stop.

By recognizing the steps—from your foot movement to the hydraulic or cable action, and finally to the pressure plate releasing its clamp—you gain the knowledge necessary to drive smoothly and diagnose minor issues early. Keep checking your fluid levels, be gentle when re-engaging the clutch, and you’ll find that driving a manual vehicle is not only rewarding but also deeply engaging. You are now equipped with the essential knowledge to master this core function of any stick-shift car.