When a clutch pedal is depressed in a manual car, you are pushing the throw-out bearing against the pressure plate fingers, which disengages the clutch disc from the engine’s flywheel. This action stops the flow of power to the wheels, allowing you to safely switch gears without grinding them.

Have you ever felt uncertain about what is actually happening under the hood when you press that third pedal? Many new drivers find the clutch system a bit mysterious. It seems like a simple push, but it involves some clever mechanics! Understanding this process is key to smooth shifting and keeping your transmission happy for years to come. Don’t worry, we’re going to break down exactly what happens when you depress the clutch pedal, using simple terms. By the end of this guide, you’ll feel a lot more confident every time you shift gears.

The Fantastic Four: Components Involved When Pressing the Clutch

To truly understand the magic that happens when you push the clutch pedal, we need to meet the main players involved in this mechanical dance. Think of these parts as a team making sure your engine power gets to the wheels only when you want it to.

When you push the pedal, you start a chain reaction that involves four essential parts, which work together to temporarily disconnect the loud, spinning engine from the quiet, stationary transmission gears.

1. The Clutch Pedal: Your Control Point

This is the part your foot interacts with. In a manual transmission car, the clutch pedal is the link between your intention (to shift) and the actual mechanical action happening deep inside the bell housing.

- Hydraulic System Link: For most modern cars across jurisdictions like the United States, the pedal is connected to a hydraulic system. Pressing the pedal pushes fluid through lines, much like how your brake pedal works.

- Cable System Link (Older Cars): Some older vehicles use a direct cable connection instead of fluid, but the end result is the same: movement is transferred to the release mechanism.

2. The Release Bearing (Throw-Out Bearing)

This small but mighty component is often the hero of the story. When you press the clutch pedal, the hydraulic or cable system pushes this little bearing forward.

Its job is critical: it’s the intermediary that physically touches the next part in line to initiate the disengagement process.

3. The Pressure Plate

The pressure plate is essentially a heavy spring mechanism housed within the larger clutch assembly. Its normal, resting job is to press the clutch disc tightly against the smooth, fast-spinning flywheel.

When the release bearing pushes against the diaphragm spring (the center part) of the pressure plate, the pressure plate moves inward, relieving the clamping force on the clutch disc.

4. The Clutch Disc

This is the friction material—think of it like a really tough brake pad sandwich. It sits between the flywheel (attached to the engine) and the pressure plate (attached to the transmission input shaft). When the pressure plate releases its grip due to your pedal push, the clutch disc is allowed to spin freely, separating the engine’s rotation from the transmission’s rotation.

Step-by-Step: What Happens When A Clutch Pedal Is Depressed

Let’s walk through the sequence of events, making sure we understand the physical chain reaction initiated by your left foot. This process is fast—usually taking less than a second—but it involves precise mechanics.

- Foot Presses the Pedal Goal: You decide you need to shift from first gear to second gear (or stop the car while still in gear). You push the clutch pedal down with your foot.

- Fluid or Cable Engagement: The mechanical movement of the pedal forces hydraulic fluid out of the master cylinder or pulls a heavy cable. This force travels down the line toward the transmission housing.

- The Push on the Bearing: The fluid pressure or cable pull actuates the slave cylinder (or lever arm), which in turn pushes the release bearing (throw-out bearing) forward, toward the spinning engine area.

- The Moment of Disengagement: The release bearing makes contact with the center of the pressure plate’s diaphragm spring. Because the bearing is moving toward the engine and the pressure plate is spring-loaded away from the engine, the pressure plate is forced to retract its clamping force.

- Power Cut Off: With the pressure plate pulled back, the friction material of the clutch disc is no longer squeezed between the flywheel and the pressure plate. The engine is now disconnected from the transmission input shaft.

- Gears Are Free: With no engine power being transmitted, the input shaft of the transmission stops receiving rotational force. This allows you to move the gear selector (shifter) into neutral or into the desired new gear without any resistance or grinding sounds.

When you lift your foot off the pedal, the hydraulic pressure releases, the pressure plate springs back to its original position, clamps the clutch disc tightly against the flywheel, and power transfer resumes. Smooth operation depends on these parts moving fluidly!

Understanding the Hydraulic System Check

Because most modern cars use hydraulics, it’s helpful to know what keeps that system working correctly. If you ever feel your clutch pedal is spongy or doesn’t fully disengage, it might be an air bubble in the system.

For smooth operation, you need clean, pressurized fluid. If you notice fluid leaks near the pedal (master cylinder) or near the transmission (slave cylinder), you might need a clutch system bleed, similar to bleeding brakes. You can find reliable tutorials on hydraulic procedures from organizations like the National Highway Traffic Safety Administration (NHTSA) regarding vehicle maintenance best practices.

Visualizing the Clutch Action: Engaged vs. Disengaged

A simple table can really help clarify the two main states of the clutch system. Notice the difference in pressure and connection between the engine (flywheel) and the transmission.

| State | Pedal Position | Pressure Plate Action | Power Transfer | Purpose |

|---|---|---|---|---|

| Engaged (Normal Driving) | Foot Off Pedal | Clamps tightly against the disc | Engine power flows to wheels | Moving the car forward |

| Disengaged (Shifting/Stopped) | Foot Pressed Down | Pulls back, releasing the disc | Engine power flow is interrupted | Allowing smooth gear changes |

What If Things Go Wrong? Common Clutch Pedal Problems

As a new driver or DIY enthusiast, you might encounter specific symptoms related to the clutch pedal. Knowing what the pedal should feel like is your first line of defense against bigger repairs.

Feelings That Signal Trouble

The pedal itself can give you clues about the health of the entire assembly. Pay attention to these sensations:

- Spongy or Soft Pedal: This often points to air in the hydraulic line, or low/contaminated fluid. The system isn’t building enough pressure to fully release the clutch.

- Hard Pedal (Requires Much Force): This usually means a major problem with the pressure plate springs or a failed pilot bearing, making it very hard for the throw-out bearing to operate.

- Pedal Goes to the Floor and Stays There: A sudden loss of resistance usually means a catastrophic failure in the hydraulic system, like a burst hose or total leakage from the master or slave cylinder.

The Sound Check: What You Hear

The noise accompanying your pedal action is just as important as the feel. If you hear noises when the pedal is depressed, it usually means the release bearing—the component doing the direct work—is failing.

A squealing or grinding sound only when the pedal is pressed down often indicates a worn-out or misaligned release bearing. If the noise happens when the pedal is up (engaged), the problem is likely with the general clutch disc or flywheel components.

Remember, the goal of pressing the pedal is to create quiet space between the engine and transmission. If you hear noise during that quiet time, it means something isn’t quite separating correctly.

Why Does This Matter for Driving Skill?

Understanding the mechanics behind the clutch pedal directly translates into better driving technique. Smooth drivers aren’t just lucky; they understand the system timing.

When you press the clutch, you are removing the engine’s power influence from the transmission. When you lift off, you are reapplying that power. In between those two actions, you must select the new gear ratio.

Perfecting the Shift Timing

The most crucial timing involves the relationship between the pedal and the gas pedal (accelerator).

- Depress Clutch & Release Gas: Simultaneously, to stop power delivery.

- Shift Gear: Quickly, while the clutch remains fully depressed.

- Release Clutch & Apply Gas: Slowly blending the two back together to match engine speed with the new transmission speed.

If you release the pedal too fast while the clutch disc is still trying to grab the flywheel, you get a sudden lurch or stall, which is called “dumping the clutch.” This jerky motion wears out your transmission mounts and stresses the friction material.

The Role of the Flywheel and Clutch Disc Wear

The clutch disc is designed to wear out over time because it’s the sacrificial friction component. As the friction material thins, the pressure plate has to extend further outward to clamp it against the flywheel. This means you have less room for the throw-out bearing to push before it hits the point of disengagement.

This leads to the common symptom of needing to press the clutch pedal almost to the floorboard (high engagement point) before the car actually shifts. This reduced travel is a clear indicator that the clutch assembly needs replacement soon. Proactive maintenance here saves you from roadside failure!

Maintenance Tips for Clutch Longevity (Even Though You Don’t Repair It)

While you might not be removing the transmission to replace the clutch assembly yourself right away, how you operate the pedal directly affects how long those parts last. These simple habits can save you significant money in the long run.

What to Avoid Doing

- Riding the Clutch: Never rest your foot on the clutch pedal while driving, especially when cruising or waiting at a stoplight. Even slight pressure engages the release bearing, causing premature wear on that bearing and the pressure plate—kind of like riding the brakes.

- Over-Revving When Shifting: Avoid flooring the gas pedal (wide-open throttle) while the clutch is only partly engaged during the shift transition. Wait until the clutch is fully engaged before hitting the gas hard.

- Shifting Without Clutch (Bouncing): Never try to force the shifter into gear without pressing the pedal. You might “pop” the gear in, but you risk bending the synchronizer rings inside the transmission, which are expensive to replace.

For more in-depth information on how your vehicle components wear over time, resources from reputable automotive engineering societies can provide detailed insights into friction material durability.

The Clutch System Across Different Vehicle Types

While the fundamental principle of disengaging the engine from the transmission remains the same for any manual transmission, the feel and mechanism can differ slightly based on the vehicle type.

| Vehicle Type | Typical Clutch Feel | Why it Differs |

|---|---|---|

| Economy Car/Sedan | Light and smooth action. | Smaller, lighter engine torque requires less clamping force. |

| Sports Car/High-Performance | Stiffer, often requires a harder push. | Needs much higher clamping force to handle high engine torque without slipping. |

| Heavy Duty Truck/Towing Vehicle | Very heavy, requires significant leg strength. | Massive torque loads require extremely robust pressure plates and discs. |

If you are driving different vehicles frequently, noticing these differences highlights just how precisely engineered the system is for the specific power output of that engine. What feels normal in your small car would likely feel dangerously soft if used in a large pickup truck.

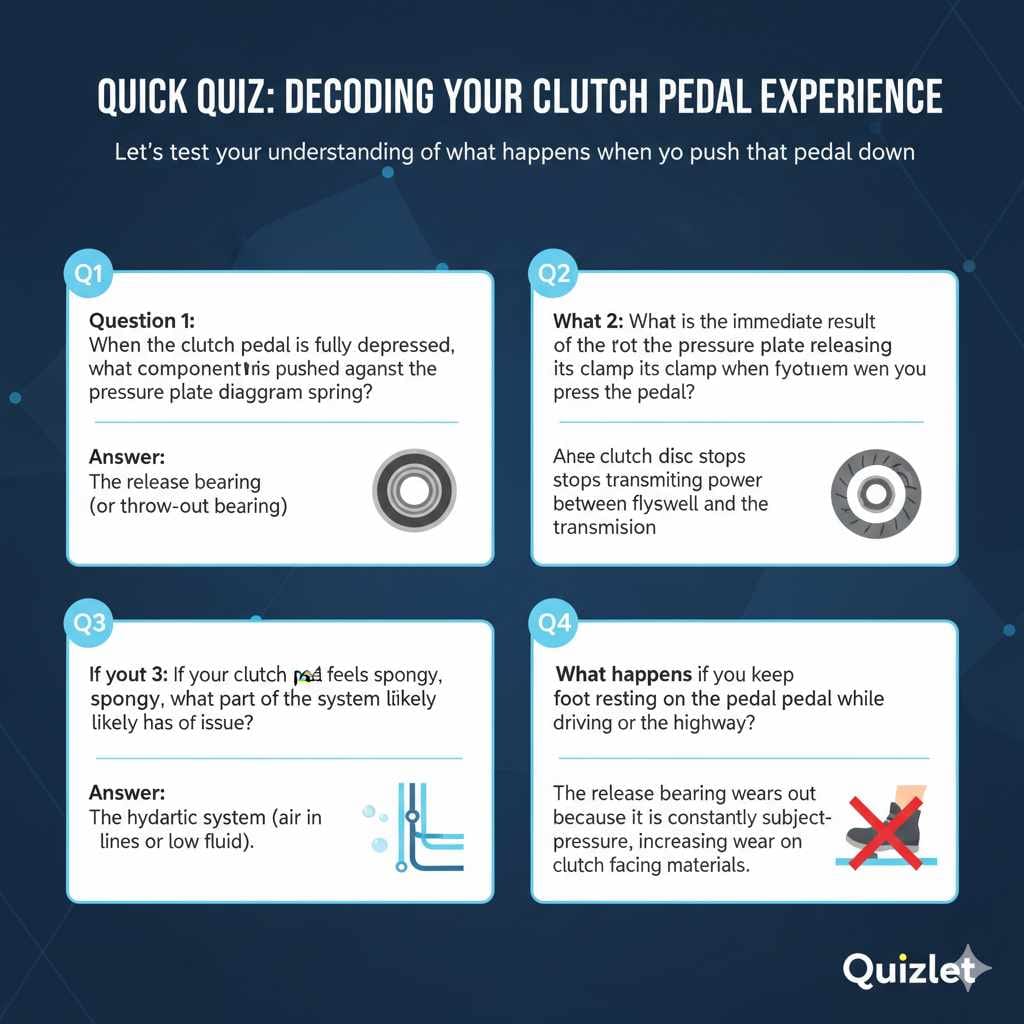

Quick Quiz: Decoding Your Clutch Pedal Experience

Let’s test your understanding of what happens when you push that pedal down. This quick check will solidify the key concepts we’ve covered.

- Question 1: When the clutch pedal is fully depressed, what component is pushed against the pressure plate diaphragm spring?

- Answer: The release bearing (or throw-out bearing).

- Question 2: What is the immediate result of the pressure plate releasing its clamp when you press the pedal?

- Answer: The clutch disc stops transmitting power between the flywheel and the transmission.

- Question 3: If your clutch pedal feels spongy, what part of the system likely has an issue?

- Answer: The hydraulic system (air in the lines or low fluid).

- Question 4: What happens if you keep your foot resting on the pedal while driving on the highway?

- Answer: The release bearing wears out prematurely because it is constantly subjected to light pressure, increasing wear on the clutch facing materials.

Frequently Asked Questions (FAQ) for Beginner Drivers

Q1: Why does my manual car stall if I don’t press the clutch pedal all the way down when stopping?

A: If you don’t press the pedal fully, the clutch disc is still partially clamped to the flywheel. The engine spins fast, but the transmission input shaft is slightly resistant. If the engine speed drops too low (like when you stop), the engine stalls because it cannot overcome that small amount of resistance. Full depression ensures complete separation.

Q2: What is “clutch drag,” and how does pressing the pedal affect it?

A: Clutch drag is when the clutch doesn’t fully disengage even though you’ve pressed the pedal. This often happens if the hydraulics are weak or the clutch plate is warped. It makes it hard to shift into first gear when stopped, as the transmission gear is still fighting the spinning engine.

Q3: How long should a clutch typically last before needing replacement?

A: This varies greatly, but under normal driving conditions (no heavy towing, no racing), a clutch can last anywhere from 50,000 to 100,000 miles. It depends heavily on the driver’s habits—how often they “ride” or slip the clutch.

Q4: Is it bad to shift into reverse without pressing the clutch pedal fully?

A: Yes. Reverse gear in most manual cars lacks synchronizers, meaning the gears must fully stop spinning to mesh properly. If the clutch isn’t fully depressed, the gears will clash, causing a loud grind. Always ensure the pedal is hitting the floorboard before attempting to select reverse.

Q5: Does a broken clutch pedal linkage mean I don’t have a clutch problem?

A: Not necessarily. If the pedal linkage (the hydraulic line or cable) breaks, you lose the ability to actuate the release mechanism. This causes the symptoms of a clutch failure (you can’t shift), but the problem lies in the connection, not necessarily the friction parts themselves.

Q6: Why are some clutch pedals much higher off the floor than others?

A: The height relates to the pedal assembly adjustment and the wear level of the clutch disc. A higher engagement point usually means the clutch disc is substantially worn, requiring the pedal to travel further to fully disengage the clamping force.

Conclusion: Confidence in Your Clutch Control

You’ve now learned exactly what happens beneath the hood the moment your foot depresses the clutch pedal. It’s a synchronized, mechanical event designed to safely isolate your engine’s power source from your transmission gears, allowing you to select the perfect ratio for any driving situation. By understanding the roles of the pedal, the hydraulic system, the release bearing, the pressure plate, and the clutch disc, you move past simply operating a car to actively understanding its performance.

Remember that while this system is durable, its lifespan is directly tied to how gently you treat it. Avoid resting your foot on the pedal, and always ensure a complete engagement and disengagement when shifting. By respecting the mechanics—knowing when to push and when to let go—you gain confidence, drive smoother, and keep your vehicle running reliably for many miles ahead. Keep practicing those smooth shifts, and enjoy the control you have over your manual transmission!