Fixing the P0700 code simply means the Transmission Control Module (TCM) has detected an issue in the transmission system that needs attention. This code itself is just an alert; you must check for underlying codes (like P0705) using an OBD-II scanner to diagnose and repair the specific fault, often involving sensors, wiring, or the TCM itself.

Seeing a check engine light pop up is never fun. When that light is accompanied by codes related to your transmission, it can feel even more stressful. If you see the diagnostic trouble code (DTC) P0700 illuminated on your dashboard, take a deep breath! This code means your car’s computer has noticed a problem with the Transmission Control System (TCS).

The good news is that P0700 is usually not an emergency that requires you to pull over immediately. It’s an indicator, sort of like a general “check the transmission area” note from your car. This code doesn’t pinpoint the exact problem; it just tells you the Transmission Control Module (TCM)—the brain for your gears—has set another, more specific code.

We are going to walk through exactly what P0700 means, why it shows up, and the safe, straightforward steps you can take to figure out the real issue underneath. By the end of this guide, you will feel confident knowing how to handle this common alert without immediately heading to the most expensive mechanic in town.

Understanding the P0700 Code: The Transmission Alert

The P0700 code is one of the most common transmission-related codes you might encounter. It’s critical to understand that P0700 is what we call a “master code” or a general notification code.

What Exactly is the P0700 DTC?

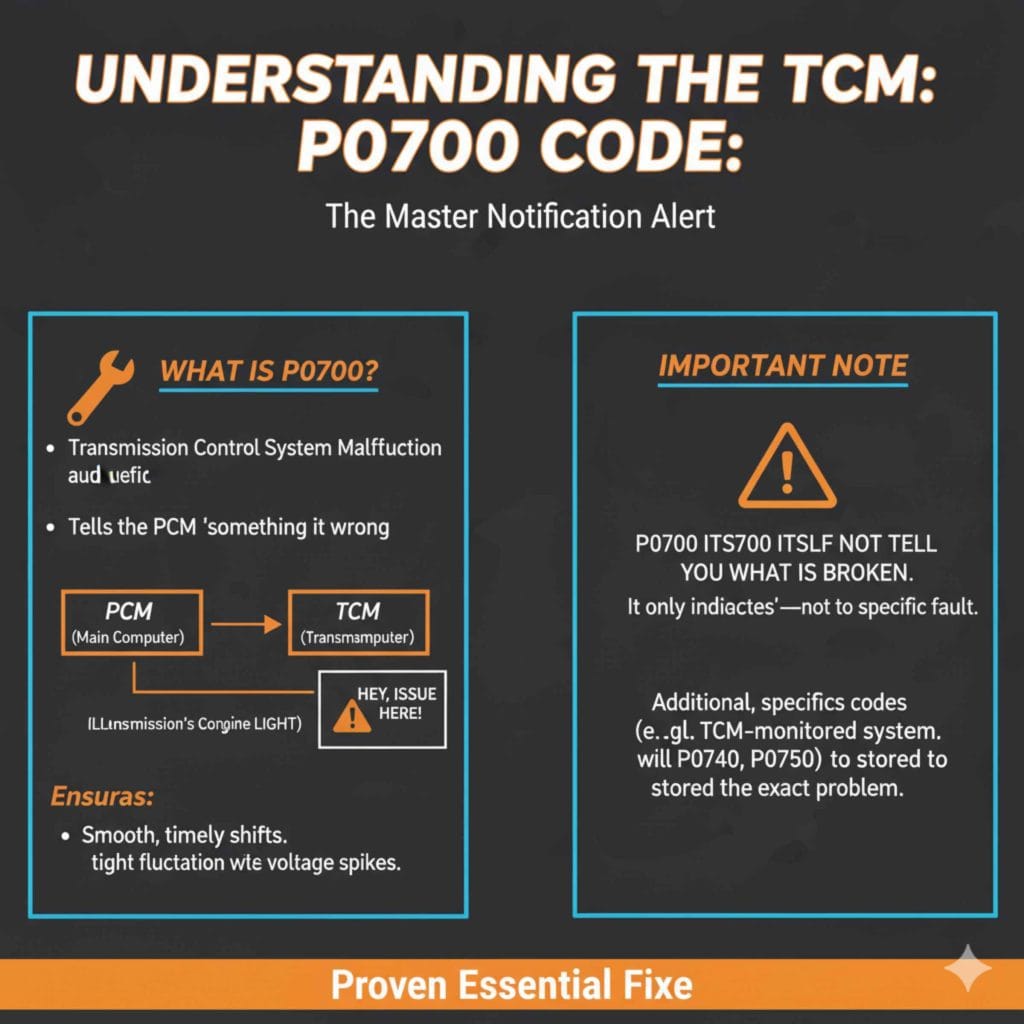

P0700 stands for “Transmission Control System Malfunction.” Think of your car’s systems like a large office building. The main computer (the Powertrain Control Module or PCM) oversees everything. If there’s an issue specifically within the transmission’s dedicated computer (the TCM), the TCM tells the PCM, “Hey, something is wrong over here!” The PCM then illuminates the Check Engine Light and stores code P0700.

The P0700 code itself does not tell you what is broken; it only tells you that something is broken inside the system monitored by the TCM.

The Crucial Next Step: Finding the Secondary Code

Because P0700 is just a signpost, you must use an OBD-II code reader or scanner to retrieve the actual diagnostic trouble code that caused the P0700 to set. These secondary codes are much more helpful. They usually look like P07XX (where XX is any number combination) and point directly to the specific component that failed.

For example, a common secondary code that triggers P0700 is:

- P0705: Transmission Input/Turbine Speed Sensor Circuit Malfunction (often related to the Neutral Safety Switch).

- P0720: Output Speed Sensor Circuit Malfunction.

You cannot effectively fix the P0700 error until you retrieve these secondary codes. It’s like calling your friend and them saying, “I have a problem here,” without telling you where “here” is!

Common Causes Behind the P0700 Error

Once you have your secondary code, the list of potential culprits narrows down significantly. However, several common areas are prone to causing the TCM to raise the P0700 flag. Let’s review the anatomy of the system that most often fails.

1. Faulty Sensors and Switches

Modern transmissions rely heavily on electronic sensors to tell the TCM what is happening inside—things like vehicle speed, gear position, and temperature. If one of these sends incorrect data, the TCM gets confused and sets the code.

- Vehicle Speed Sensor (VSS): If the VSS fails, the TCM doesn’t know how fast the car is moving, leading to shifting issues and setting P0700.

- Transmission Range Sensor (TRS) or Neutral Safety Switch: This tells the car if it is in Park, Drive, or Reverse. If it fails, the car might start in gear, which is a major safety concern.

- Input/Output Speed Sensors: These monitor the rotation speed of the transmission shafts.

2. Wiring and Electrical Connections

This is often the cheapest fix, but also the hardest to spot. Wires leading to the transmission sensors, solenoids, or the TCM itself can become damaged.

- Corrosion on connectors due to moisture or road debris.

- Frayed, cut, or melted wiring harnesses near hot engine components.

- Loose plug connectors that vibrate free during driving.

3. Transmission Control Module (TCM) Failure

The TCM is an electronic module, and like any computer, it can fail over time due to heat, age, or electrical spikes. If the TCM itself is faulty, it can sometimes report a general error (P0700) while it struggles to operate correctly.

4. Low or Old Transmission Fluid

While low fluid usually causes mechanical shifting problems first, severely low fluid levels can sometimes cause sensor readings to become erratic. Additionally, the fluid needs to be clean to lubricate internal components and help the solenoids operate smoothly. Very old, burnt fluid can contribute to electronic control failures.

To help you organize your diagnosis, here is a quick comparison of the typical P0700 follow-up codes:

| Secondary DTC Example | Component Affected | Likely Repair Area |

|---|---|---|

| P0705 | Transmission Range Sensor (TRS) | Wiring or the sensor itself on the side of the transmission case. |

| P0721 | Output Speed Sensor (OSS) | Sensor near the output shaft or its wiring harness. |

| P0751 | Shift Solenoid A Performance | Internal solenoid or the wiring leading to it. |

Step-by-Step Guide: How Do You Fix P0700 Transmission Control System Malfunction?

We are going to approach this fix methodically, starting with the easiest and cheapest checks first. Remember, diagnosing P0700 is really about diagnosing the other code it is reporting!

Step 1: Retrieve and Document All Codes

This is mandatory. If you skip this, you are just guessing. You need an OBD-II scanner. These can be purchased relatively cheaply now, or most major auto parts stores will scan your codes for free.

- Locate the OBD-II port (usually under the dashboard near the steering wheel).

- Plug in your scanner and turn the ignition key to the “ON” position (engine off).

- Read and write down every single code displayed. Pay close attention to the codes starting with P07XX.

- Clear the codes using the scanner (this is temporary, designed just to see if the P0700 returns immediately).

Step 2: Initial Visual Inspection (Safety First!)

Before you touch anything electrical, look at what you can see. Always make sure the car is turned off, the parking brake is engaged, and the vehicle is stable before working underneath it.

- Check Fluid Level and Condition: Check your transmission fluid dipstick (if equipped). Is the level correct? Is the fluid bright red/pink or dark brown/black? Does it smell burnt? If the fluid is very low, top it up immediately, but know this is a temporary fix until you find the leak.

- Examine the Wiring Harness: Trace the main wiring harness that plugs into the side or top of the transmission case. Look for obvious signs of rubbing, melting, physical cuts, or heavy corrosion on the connectors. If you find corruption, your issue is likely electrical.

- Check Fuses: Consult your owner’s manual to locate the fuse box that protects the TCM circuit. A blown fuse can cause the TCM to report an error.

Step 3: Addressing Specific Secondary Codes

Now you use the specific code you retrieved in Step 1 to focus your repair efforts. Here are common actions based on the type of code found:

If the Code Points to a Sensor (e.g., P0705, P0720):

Sensors are usually bolt-in parts accessible from the top or side of the transmission housing.

- Locate the Sensor: Use your repair manual or an online resource specific to your vehicle year, make, and model to find the exact location of the faulty sensor (e.g., the Transmission Range Sensor).

- Disconnect and Inspect: Disconnect the electrical plug carefully, checking for bent pins or moisture inside the plug.

- Test or Replace: If you have a multimeter (a tool for measuring voltage and resistance), you can test the sensor according to factory specifications. For affordability and ease, if the sensor is old, replacing it entirely is often the most straightforward DIY fix. Always purchase high-quality replacement parts, as cheap electrical components often fail quickly.

Pro-Tip for Sensor Replacement: When replacing external sensors, sometimes the old O-ring can stick in the housing. Make sure the new sensor seats perfectly flat against the transmission to ensure an accurate reading.

If the Code Points to a Solenoid (e.g., P0750):

Solenoids are electronic valves inside the transmission that control fluid flow for shifting. Accessing these requires dropping the transmission pan on most vehicles.

- Safety Precaution: Transmission fluid is hot and messy. Ensure the car is safely supported if you need to remove the pan. Dispose of old fluid responsibly.

- Pan Removal: Carefully remove the transmission pan bolts, allowing the fluid to drain into a clean pan.

- Replace the Solenoid: The solenoid pack is usually bolted near the valve body. Disconnect the electrical connector(s), unbolt the faulty solenoid, and carefully install the new one. Ensure the gaskets are seated correctly before reinstalling the pan.

- Refill: Refill the transmission with the manufacturer-specified fluid type, checking the level while the car is running and warm, as directed by the service manual.

Step 4: Clearing Codes and Road Testing

Once you have replaced the faulty sensor or solenoid, you must clear the stored codes with the scanner.

- Clear all codes (P0700 and the secondary code).

- Take the vehicle for a test drive, replicating the conditions under which the light originally came on (if known).

- If the P0700 does not immediately return, you have likely fixed the issue! If it returns instantly, or if a new code appears, you may have an issue with the wiring harness or the TCM itself.

Step 5: Dealing with Wiring and TCM Issues

If replacing components doesn’t solve the problem, the issue is deep in the electrical system.

Wiring Harness Repair: If you find a damaged wire, you must repair it properly. This usually involves splicing in a new section of matching gauge wire and using heat-shrink waterproof connectors. A poor wire repair will cause the code to return quickly.

TCM Replacement: A failing TCM is the last resort diagnosis. TCMs are expensive and often require professional programming or “flashing” by a dealership or specialized shop to communicate correctly with your engine’s PCM. Before authorizing a TCM replacement, ensure every other simple component has been tested and verified to be working correctly, including grounds and power supply wires leading to the module.

For more detailed diagnostic procedures on specific electrical circuits, always consult reputable OEM information sources, such as those provided by organizations focused on vehicle repair standards. The National Highway Traffic Safety Administration (NHTSA) emphasizes the importance of standardized diagnostic procedures for vehicle safety systems.

Essential Tools for Diagnosing P0700

You don’t need a full mechanic’s toolbox to tackle the first few steps of fixing P0700, but having the right equipment makes the job much easier and safer.

| Tool | Why You Need It | Beginner Tip |

|---|---|---|

| OBD-II Code Reader/Scanner | Essential for retrieving the secondary code that controls P0700. | Buy one that can read live data, not just codes. |

| Basic Socket Set & Wrenches | Used to remove sensor bolts, drain plugs, or pan bolts. | Keep metric and standard sets handy; many vehicles mix sizes. |

| Multimeter (Digital) | Necessary for testing voltage, continuity, and resistance on solenoids and sensors. | Start by learning how to test a simple fuse for continuity. |

| Safety Gear | Gloves, safety glasses, and proper jack stands (never use only a jack!). | Always wear glasses when working under the car or handling fluids. |

Preventative Maintenance to Avoid Future P0700 Codes

The best way to fix the P0700 is to prevent it from ever setting! Transmission issues are often related to neglect of simple maintenance items. Focus on these areas to keep your transmission healthy and the TCM quiet:

- Stick to Fluid Service Intervals: This is the number one way to keep electronic transmissions happy. Follow your manufacturer’s schedule for transmission fluid and filter changes religiously. This prevents sludge buildup that gums up solenoids and causes erratic sensor readings.

- Monitor for Leaks: Keep an eye on your driveway. Any sign of red or brown fluid should be addressed immediately. Low fluid causes overheating and poor lubrication.

- Address Engine Misfires Quickly: While it seems unrelated, a severe engine misfire (which might set a P0300 code) can sometimes confuse the communication between the PCM and TCM, occasionally triggering ancillary transmission codes.

- Avoid Extreme Driving Conditions: Excessive towing or hauling heavy loads beyond your vehicle’s rating puts immense heat and stress on the transmission components, accelerating wear on internal electronics and sensors.

Frequently Asked Questions (FAQ) About P0700

Q1: Can I still drive my car if the P0700 code is present?

A: Generally, yes, you can drive cautiously for a short time. However, because P0700 means there is an underlying issue, you might experience poor shifting, delayed engagement, or slipping. Drive only to a safe location or repair shop. If the transmission starts making loud noises or overheating, stop driving immediately.

Q2: Is P0700 an expensive repair?

A: It depends entirely on the secondary code. If the fix is a simple external sensor or a wiring repair, it can be inexpensive ($100–$300). If the code points toward the TCM failing or a complex internal solenoid pack failure, the cost can rise quickly, often into the thousands.

Q3: How long does it take to fix the P0700 code?

A: A simple sensor replacement might take an hour or two if you have the right information. If you need to drop the heavy transmission pan to access internal components, it can take half a day, plus time for the fluid refill and settling.

Q4: Does clearing the code fix the P0700 error?

A: No. Clearing the code with a scanner only resets the light temporarily. If the underlying problem is still present (like a bad sensor that isn’t sending the right signal), the TCM will detect the fault again, and the P0700 will return within a few drive cycles.

Q5: My P0700 went away after I topped up the transmission fluid. Is it fixed?

A: You may have solved the symptom, but not the root cause. If fluid was low, you have a leak that needs investigation. Keep monitoring the fluid level closely. A leak that results in low fluid can quickly damage the transmission if ignored.

Q6: Can a dead battery cause the P0700 code?

A: Low voltage or power fluctuations can sometimes confuse sensitive electronic modules like the TCM, causing them to set a generic fault code. Always check battery health and system voltage before diving deep into transmission diagnostics.

Conclusion: Taking Control of Your Transmission Alert

Encountering the P0700 code can feel intimidating at first, but understanding its true meaning changes everything. P0700 is not a diagnosis—it is a notification. It simply tells you that the Transmission Control Module has detected a problem and is asking you to look deeper. The real solution lies in identifying and addressing the secondary transmission codes that accompany it.

By approaching P0700 methodically—starting with scanning for all codes, performing basic visual inspections, checking transmission fluid, and then focusing on the specific sensor, solenoid, wiring, or electrical issue indicated—you avoid unnecessary guesswork and expensive repairs. In many cases, the fix is straightforward: a faulty speed sensor, a corroded connector, low fluid, or a damaged wire. These are manageable repairs that do not require rebuilding or replacing the entire transmission.

Only after eliminating simple causes should more complex possibilities like internal solenoid failures or a failing TCM be considered. Even then, proper diagnosis can mean the difference between a targeted repair and an avoidable four-figure bill. Clearing codes alone is never a fix—but using codes as a roadmap is the smartest way forward.

Most importantly, preventative maintenance plays a huge role. Keeping transmission fluid clean and at the correct level, maintaining good battery voltage, fixing leaks early, and addressing warning signs promptly will significantly reduce the chances of seeing P0700 again.

In short, P0700 is your vehicle’s early warning system—not a verdict. With the right tools, a calm step-by-step approach, and an understanding of what the code truly represents, you can confidently diagnose the issue, make informed repair decisions, and protect your transmission from long-term damage.