Getting a warning light, like the check engine light, can be a little stressful. Especially when it says there’s a problem with your transmission. The Fix Transmission Control System MIL Request: Easy Guide is something many people search for because this issue can seem tricky at first. Don’t worry, it doesn’t have to be. We’re here to help make things clear and simple. We will give you a step-by-step approach to tackle this issue. Let’s get started and clear up that warning light.

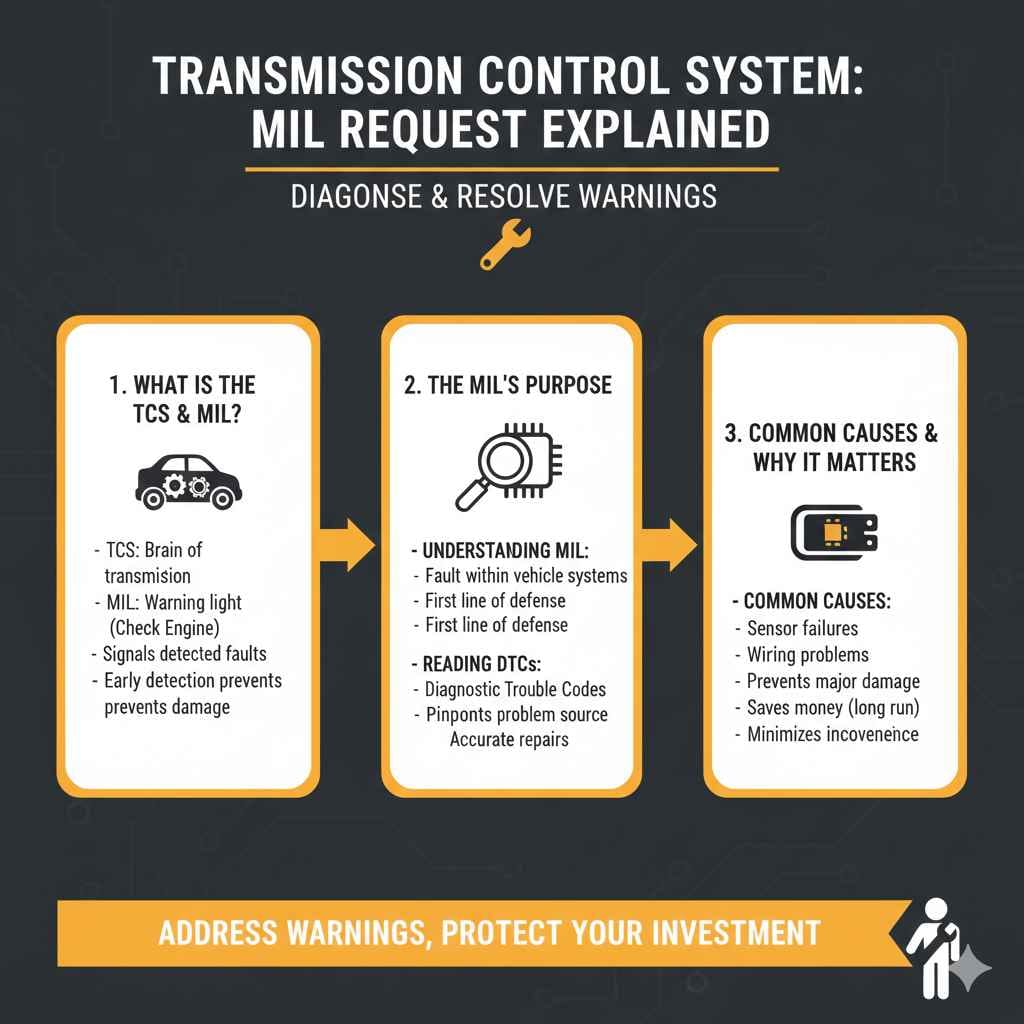

What Is a Transmission Control System and Why Does It Matter?

The transmission control system (TCS) is like the brain of your car’s transmission. It’s in charge of making sure your car shifts gears smoothly and efficiently. This system uses sensors to gather information about how fast your engine is running, how fast your car is moving, and how hard you’re pressing the gas pedal. Based on this data, the TCS tells the transmission when to change gears. It’s all about getting the right balance of power and fuel economy. A functioning TCS is essential for a smooth and enjoyable driving experience. Without it, your car may shift roughly, use more fuel, or even get stuck in a single gear.

The Role of the MIL (Malfunction Indicator Lamp)

The MIL, often called the check engine light, is your car’s way of telling you something’s not right. When the TCS detects a problem, it sends a signal that turns on the MIL. This light can mean anything from a loose gas cap to a more serious issue with your transmission. If you see the MIL illuminated, it’s always a good idea to have it checked out. Ignoring it could lead to bigger problems down the road. The system monitors many components related to the transmission. This is a crucial element that informs drivers about the vehicle’s operating status.

- Understanding the MIL’s Purpose: The MIL serves as a warning, signaling that a fault has been detected within the vehicle’s systems.This light doesn’t just come on for fun. It’s triggered when the car’s computer identifies an issue with a system, like the transmission control. The MIL is your first line of defense; it lets you know when something needs attention. When it lights up, it indicates a problem that could impact how your car performs and could potentially lead to more expensive repairs if ignored. Addressing the underlying issue is critical for maintaining vehicle health.

- Reading Diagnostic Trouble Codes (DTCs): DTCs provide specific clues about the fault.When the MIL lights up, your car’s computer stores a DTC. These codes act like clues, pinpointing the source of the problem. You can access these codes using a diagnostic scan tool. The DTCs give technicians, and you, a starting point for diagnosis. Each code corresponds to a particular problem, letting you zero in on what’s going wrong. This information helps in making accurate repairs without unnecessary guesswork or part replacement.

- Common Causes for MIL Illumination Related to the TCS: Knowing these causes can help with quicker troubleshooting.Several factors can cause the MIL to illuminate due to issues with the TCS. These include sensor failures, wiring problems, and internal transmission faults. Sometimes, something as simple as a faulty sensor can trigger the light. In other cases, there might be more extensive internal damage. Identifying the specific cause is necessary for effective repair. This often begins with code scanning and might require more detailed testing. Understanding these causes allows for targeted repairs.

- Why Early Detection Matters: Addressing issues promptly can prevent major damage and high repair costs.Early action can prevent the problem from worsening and save you money in the long run. The longer you wait, the greater the chance of causing more significant damage to your transmission or other related components. Early intervention not only protects your car but can also minimize inconvenience. The goal is to address the situation promptly, often leading to simpler, less expensive fixes compared to extensive repairs down the road.

Common Problems That Trigger the MIL and How to Troubleshoot

When the MIL comes on related to your transmission, several problems might be the cause. These problems can range from minor issues, such as a faulty sensor, to more serious internal transmission damage. Recognizing these common triggers and knowing how to troubleshoot them will help you get your car back on the road. The earlier you address the problem, the better. Quick action can often prevent further damage and expensive repairs. Always keep in mind that safety should come first when checking or repairing anything on your car.

Sensor Failures and Their Impact

Sensors are essential to the TCS. They monitor different parts of the transmission. If a sensor fails, the TCS can’t get the correct data, which can trigger the MIL. These sensors include the speed sensor, the throttle position sensor, and others. A bad sensor might cause the transmission to shift poorly or not at all. Replacing a faulty sensor is often a straightforward fix. Using a diagnostic tool, a mechanic can identify which sensor is causing problems.

- Speed Sensor Issues: Discusses the impact of speed sensor failures on transmission function.The speed sensor is critical for the transmission to determine how fast the car is moving. If it’s malfunctioning, the transmission may shift at the wrong times, leading to rough shifts or a complete loss of gear selection. The car’s computer uses speed sensor data to control various aspects of the transmission operation. If the speed sensor isn’t working correctly, it’s likely the check engine light will illuminate, and your car’s performance will suffer. Replacing a faulty speed sensor is often an easier fix compared to more complex transmission issues.

- Throttle Position Sensor (TPS) Problems: Explains how the TPS affects shifting.The TPS tells the transmission control module how far the accelerator pedal is pressed. This information helps the TCS decide when to shift gears. If the TPS fails, the transmission might shift erratically or not shift at all. When the TPS fails, the transmission can’t accurately respond to your driving demands. Symptoms include delayed shifting or unexpected gear changes. The car’s performance becomes unpredictable. Diagnosing and replacing a faulty TPS is often a straightforward repair, improving your car’s response.

- Other Sensor-Related Faults: Covers other sensors that can cause MIL activation.Besides the speed sensor and the TPS, other sensors, such as the input and output shaft speed sensors, can also trigger the MIL if they fail. These sensors provide vital information about the transmission’s operation. A malfunctioning sensor can lead to the transmission entering “limp mode,” where it operates with restricted functionality. Identifying the specific sensor at fault often involves using a diagnostic scan tool. Regular maintenance and inspection of these components can help prevent potential issues and keep your car running smoothly.

- The Diagnostic Process for Sensor Problems: The steps taken to diagnose sensor faults.Diagnosis begins with checking diagnostic trouble codes (DTCs) using a scan tool. The codes will help identify which sensor is causing the problem. The mechanic might also perform a visual inspection of the sensor and its wiring for any damage. Testing the sensor’s voltage output can also provide valuable insights. Based on the findings, the mechanic will either replace the sensor, repair the wiring, or suggest further troubleshooting steps. Accurate diagnosis is essential for an effective repair. Replacing the correct sensor is necessary to restore proper transmission function.

Wiring Issues and Electrical Faults

Wiring problems and electrical faults can disrupt the flow of information to the TCS. These issues can range from broken wires to corroded connectors. Electrical problems can cause the transmission to behave erratically. They can also prevent the TCS from receiving the data it needs to function correctly. A thorough inspection of the wiring harness and connectors is necessary to identify these issues. Fixing wiring problems might involve replacing damaged wires or cleaning and reconnecting corroded connectors. Sometimes, the problem could be a faulty module that needs replacement. These steps will prevent the MIL light from illuminating.

- Common Wiring Problems: Details of various wiring issues that can lead to MIL activation.Wires can get damaged because of wear, tear, or exposure to the elements. Corroded connections can also interrupt the signal flow. Common problems include chafed wires, loose connections, or broken insulation. These issues can disrupt the signals sent to and from the TCS, leading to malfunctions and the illumination of the check engine light. Careful inspection of the wiring harness is crucial to identify and repair these problems. Wiring issues are often easier to fix than major transmission problems.

- The Importance of Connector Inspection: Focuses on the role of connectors in the system.Connectors are the points where wires connect to sensors, modules, and other components. They are vulnerable to corrosion and damage. Corroded or loose connectors can cause intermittent faults, making it difficult to diagnose the problem. A thorough inspection of all connectors involved in the TCS circuit is required. The connectors should be cleaned or replaced to ensure a good connection. This step ensures that signals can travel freely, allowing the TCS to function correctly. This is a common and often overlooked area in troubleshooting.

- Identifying and Repairing Electrical Faults: Steps on how to diagnose and fix electrical issues.Identifying and fixing electrical faults involves visual inspections, using a multimeter to check for continuity, and using a diagnostic scanner to check for codes. Start by looking for obvious signs of damage, like broken wires or corroded connectors. Use a multimeter to check the voltage and resistance. Then, consult the wiring diagrams to trace the wires and verify the connections. Repairing electrical faults can involve replacing damaged wires, cleaning connectors, or replacing damaged components. Safety should be a priority.

- Impact on TCS Function: Explains how electrical faults impact the transmission control system.Electrical faults can directly affect the TCS’s ability to operate. Problems with wiring and connectors can disrupt the flow of data to the TCS. This can lead to incorrect gear changes, rough shifting, and, in severe cases, the transmission going into “limp mode,” where it operates with limited functionality. Properly functioning electrical components are crucial for reliable and consistent performance of the transmission. Identifying and correcting electrical faults helps in restoring and maintaining the transmission’s performance and longevity.

Simple Steps to Diagnose and Potentially Fix Issues

If your check engine light comes on and you suspect a TCS problem, some steps can help diagnose the issue. These steps can also help you determine whether the problem is something you can fix yourself or if you need professional help. Safety is key, and it’s essential to follow these steps cautiously. While some problems can be fixed at home, others require special tools and experience. The right steps will point you in the right direction to keep your car running smoothly.

Using a Diagnostic Scan Tool

A diagnostic scan tool is a must-have tool for checking the MIL. This device connects to your car’s computer and reads the diagnostic trouble codes (DTCs). These codes tell you what’s wrong with your car. Scan tools can also display live data from the sensors, which can help diagnose problems. The scan tool allows you to clear the codes after the repair, which turns off the check engine light. Using a diagnostic scan tool is the first step in diagnosing TCS-related issues. They are easy to use, and you can find them at most auto parts stores.

- Choosing the Right Scan Tool: Explores the different types of scan tools available.There are several types of scan tools, from basic code readers to more advanced professional tools. A basic code reader will allow you to read and clear DTCs. These are inexpensive and great for beginners. More advanced scan tools can perform more functions, such as displaying live data, performing bi-directional tests, and providing more detailed information about your car’s systems. Consider your needs and budget when choosing a scan tool. A basic code reader is usually enough for most home repairs, but more complex problems may require a professional tool.

- Connecting and Reading DTCs: The process of connecting the scan tool and reading codes.Most cars have an OBD-II port, located under the dashboard. Connect the scan tool to this port. Turn the ignition on, but don’t start the engine. Follow the scan tool’s instructions to read the DTCs. The scan tool will display the codes and provide a brief description of what the code means. Take note of the codes. Write them down or take a picture of the screen. These codes will help diagnose the problem. The scan tool is a valuable tool for anyone working on cars.

- Interpreting Diagnostic Trouble Codes: How to understand the information provided by DTCs.DTCs provide specific information about the problem. Each code begins with a letter, followed by four numbers. The letter indicates which system is affected (P for powertrain, B for body, C for chassis, and U for network). The numbers provide more information. The first number indicates whether it’s a generic or manufacturer-specific code. The remaining numbers give you the exact problem. Look up the code online or in a repair manual for a detailed description of the problem. Interpreting the DTCs is the key to identifying the fault.

- Clearing DTCs after Repair: Discusses the importance of clearing codes after repair.After you have repaired the problem, you will need to clear the DTCs from the car’s computer. Use the scan tool to clear the codes. Follow the tool’s instructions. The check engine light should go off, indicating that the problem has been resolved. If the light comes back on after clearing the codes, there is likely still an underlying issue that needs attention. Make sure the repair is complete before clearing the codes. The check engine light will tell you if your repair has fixed the problem.

Checking Fluid Levels and Condition

Checking the transmission fluid is an easy step that can help identify potential problems. Low fluid levels can cause transmission problems, including rough shifting and slipping. Dark or burnt-smelling fluid may indicate internal damage. Always check the fluid when the engine is warm and running. If the fluid level is low, add the correct type of fluid. If the fluid is dark or smells burnt, it’s time to take your car to a mechanic for further inspection. Checking the fluid is a simple process. It’s also an important part of car maintenance, particularly for the transmission.

- Locating the Transmission Dipstick: Shows how to find the dipstick.The location of the transmission dipstick varies depending on the car’s make and model. Check your owner’s manual for the exact location. The dipstick is usually located near the transmission, often near the engine block. The dipstick will usually have a handle that you can pull out. Make sure the engine is running and warmed up before checking the fluid. The dipstick helps you check and maintain proper fluid levels. This prevents transmission problems.

- Checking Fluid Level and Color: How to check the fluid for proper level and condition.Remove the dipstick and wipe it clean. Reinsert the dipstick fully and then remove it again. Look at the fluid level on the dipstick. It should be within the range indicated on the dipstick. Also, look at the color and smell of the fluid. The fluid should be a clear, reddish color. If the fluid is dark, brown, or black, or if it smells burnt, it may be time to have your transmission serviced. Dirty fluid can damage transmission parts. Regular inspection can help to prevent major problems.

- The Meaning of Low Fluid Levels: What low fluid levels indicate.Low fluid levels can cause many problems, including rough shifting, slipping gears, and even complete transmission failure. Low levels often indicate a leak. A leak could be from a seal or a hose. If you find low fluid, you should add the correct type of fluid to the recommended level. You should also check for leaks. Ignoring low fluid can lead to severe damage. Regular checks can catch problems before they become major issues. Proper fluid levels are crucial for transmission performance.

- When to Seek Professional Help: Indicates when a mechanic’s help is needed.If you see that the fluid is low or discolored, or if the transmission is acting up, you should consult a mechanic. They will be able to perform a more thorough inspection and diagnose the problem accurately. If the transmission is leaking, it’s important to find and fix the leak as soon as possible. A mechanic can properly diagnose and fix any underlying problems. If your transmission has a major issue, it is time for a specialist. A professional can provide solutions and expert advice.

Visual Inspection and Basic Checks

A visual inspection can often reveal apparent problems with the TCS. Checking the wiring and connectors is essential. Look for any visible damage, such as frayed wires or loose connections. Inspect the transmission and its components for any signs of leaks. These simple visual checks can often help identify potential problems before they become more serious. This process may help to catch problems that you might otherwise miss. Visual inspections are a practical first step to troubleshooting TCS problems.

- Examining Wiring and Connectors: Guide for inspecting the wiring and connectors.Look carefully at the wiring harness and connectors for any visible damage. Look for frayed wires, cracked insulation, or loose connections. Pay close attention to the connectors that connect to the sensors and the transmission control module. Make sure they are securely attached and free from corrosion. If you see any damage, make repairs or

- Checking for Fluid Leaks: Identifying and inspecting potential leaks in the transmission system.Inspect the area around the transmission for any signs of fluid leaks. The transmission fluid is usually a reddish color. Check the seals around the transmission, including the pan gasket, output shaft seal, and input shaft seal. A leak can cause the transmission to lose fluid, which can lead to damage. If you see a leak, determine where it’s coming from and get it fixed. A leak can be a simple fix or might indicate a more complex problem. Addressing leaks is important for protecting the transmission.

- Looking for Physical Damage: Inspecting the components for any physical damage.Look for any physical damage to the transmission or its components. Check for dents, cracks, or other signs of damage. Any physical damage to the transmission components can indicate a serious problem. Sometimes, physical damage may be due to road hazards. This could lead to a fault. If you spot any damage, you should take your car to a mechanic for a professional inspection. The mechanic can assess the extent of the damage and recommend the appropriate repairs. Serious damage can impact the transmission’s function and reliability.

- Basic Component Checks: Checklist of things to inspect in your transmission.Here are some basic components to check: Look at the transmission pan for any signs of leaks or damage. Check the condition of the transmission cooler lines. Make sure the cooling fan is working properly. The cooler keeps the transmission fluid at the right temperature. Finally, ensure the shift linkage is working. Proper cooling is crucial for good transmission performance. Make sure all of these components are working together for proper transmission function. These basic checks are essential in early detection.

When to Seek Professional Help and What to Expect

While some TCS problems can be fixed at home, others require the skills and equipment of a professional mechanic. Knowing when to get professional help is important. Also, understanding what to expect during a professional repair will make the process easier. Safety, accuracy, and the right tools are all essential for a proper repair. Many complex repairs and diagnostics require professional knowledge. The right approach is vital for the best results.

Recognizing the Limits of DIY Repairs

There are limits to what you can repair yourself. Some repairs require specialized tools and knowledge. Attempting repairs beyond your skill level can be dangerous and could make the problem worse. If you’re not comfortable with auto repair, it’s best to seek help from a professional. The decision to fix it yourself should be based on your knowledge and skill set. If you are uncertain, a professional mechanic can provide the best solution and keep you safe.

- Advanced Diagnostic Procedures: Understanding the complexity of advanced diagnostics.Advanced diagnostic procedures often involve using specialized scan tools. Also, they include detailed testing of sensors, modules, and wiring. These tests often require the ability to interpret technical data and read wiring diagrams. The procedures also involve testing the signals that the various components use. A professional has the experience and tools to perform these tests accurately. They have the knowledge to correctly diagnose any problem.

- Specialized Tools and Equipment: Tools and equipment only found in professional shops.Some repairs require special tools. These tools are often expensive and only found in professional repair shops. These tools can include transmission rebuild kits, specific diagnostic equipment, or special alignment tools. Trying to perform a repair without the right tools can be frustrating and may lead to poor results. Working with the right tools ensures that the repair will be done correctly. It’s often more cost-effective to get professional help than to buy the tools for a one-time repair.

- The Importance of Experience and Expertise: The value of professional expertise in repairs.Professional mechanics have years of experience. They have the experience to quickly identify and fix problems. They know how to accurately diagnose and resolve complex issues. They have seen problems before and know the best way to approach them. Their knowledge helps to ensure that repairs are done correctly and efficiently. You can trust a professional mechanic to find the problem.

- Safety Considerations: Emphasizing the need for safety when undertaking repairs.Working on cars can be dangerous. It’s important to take safety seriously. Always wear safety glasses and gloves. Work in a well-ventilated area. Make sure your car is properly supported on jack stands before getting underneath it. If you’re not confident in your ability to do a repair safely, it’s better to get professional help. The goal is to perform repairs safely and not risk injury or damage to your car. If you are unsure, ask a professional.

What to Expect at the Mechanic

Taking your car to a mechanic can be a little intimidating, but knowing what to expect can help. The process usually begins with a diagnosis. The mechanic will use a scan tool and other equipment to identify the problem. The mechanic will then provide you with an estimate of the repairs. You will work through the best solution together. They will tell you what needs to be fixed and how much it will cost. Once you approve the work, they’ll make the repairs. The goal is to give you a clear view of the process and what to expect.

- The Diagnostic Process: The steps a mechanic takes to diagnose the problem.The diagnostic process starts with a thorough inspection of your car. The mechanic will use a scan tool to read the DTCs. Then, they will perform various tests to pinpoint the problem. They might check fluid levels, inspect wiring, and test sensors. They will also look for any signs of leaks or physical damage. The process is thorough. It helps them to understand exactly what is wrong. Proper diagnosis is the first step in a successful repair.

- Receiving and Understanding the Estimate: Steps to consider before approving a repair.Once the mechanic has diagnosed the problem, they will provide you with an estimate of the cost of the repairs. The estimate should include a breakdown of the parts, labor, and any other fees. Carefully review the estimate to make sure you understand everything. Ask the mechanic questions if anything is unclear. Make sure the estimate is clear and complete. Knowing what to expect makes things easier.

- Communication and Repair Process: Explaining what happens during the repair.Throughout the repair process, the mechanic should communicate with you. They should keep you informed of their progress. They should explain any additional problems that arise. If they find anything that wasn’t included in the original estimate, they should inform you before they do the work. They should be clear and open to your questions. This keeps you informed during the process. Having clear communication is key.

- Questions to Ask the Mechanic: Tips for asking informed questions.Don’t be afraid to ask questions. You can ask why they recommend a particular repair, the cost of the parts, and how long the repair will take. Ask about the mechanic’s experience with the specific problem. Get all the information you need to make an informed decision about the repair. This also helps you understand the process. Getting informed ensures a better experience.

Practical Examples and Troubleshooting Scenarios

Seeing real-world examples can help you understand how to approach TCS problems. These examples show how the steps can apply in various situations. It will explore real-life experiences and scenarios. These examples make the information more relatable and can provide practical solutions. Use these examples to understand and fix common issues.

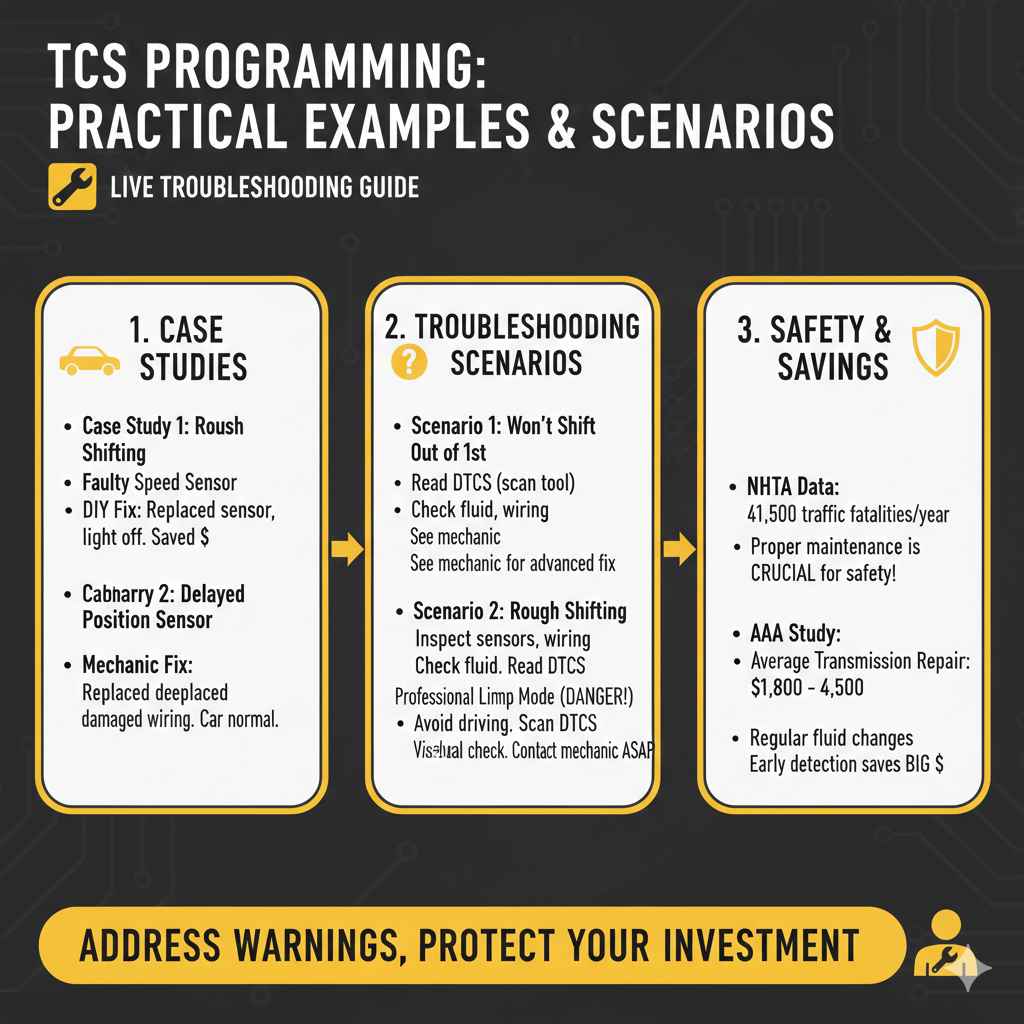

Case Study 1: Rough Shifting

A driver noticed that their car was shifting roughly. The check engine light came on. Using a scan tool, they found a DTC related to the transmission speed sensor. After researching the code, they decided to replace the sensor themselves. After replacement, the rough shifting stopped, and the check engine light went out. The driver saved money by doing the repair at home. This is a common and easy-to-fix problem.

Case Study 2: Delayed Shifting

A driver reported that their car had a delay when shifting gears. They took their car to a mechanic. The mechanic used a scan tool and found a code related to the throttle position sensor. After a visual inspection, the mechanic found that the wiring harness to the sensor had been damaged. The mechanic replaced the wiring harness. The car shifted normally after the repair. This fixed the problem and got the car back on the road.

- Scenario 1: Your check engine light comes on, and your car won’t shift out of first gear.You can use a scan tool to read the DTC. Then, you can determine if the problem is something you can fix yourself. First, check your transmission fluid level. Next, visually inspect the wiring and connectors around the transmission. If there are no obvious signs of damage, you might need to take your car to a mechanic. They will have advanced tools to diagnose and fix the problem.

- Scenario 2: You notice that your car shifts roughly, especially when cold.This may be a sign of a problem with the sensors or the TCS. Begin with a visual inspection of the sensors. Examine the wiring and connectors. Also, you can check the transmission fluid. If everything looks okay, use a scan tool to read any DTCs. The DTCs can help you focus on the cause of the rough shifting. You may have to take your car to a mechanic if the problem is not easy to solve.

- Scenario 3: The check engine light comes on, and your car goes into “limp mode”.This is a warning sign that the transmission is experiencing a serious issue. You should avoid driving the car if the transmission has gone into limp mode. Scan the car for a DTC. Then, visually check for any signs of damage. Contact a mechanic right away. This problem could cause more damage, so it is important to act quickly. You may need professional assistance to restore your car to normal function.

According to the NHTSA, there were 41,500 traffic fatalities in the United States in a recent year. This number indicates the importance of maintaining your vehicle. Proper transmission function is important for your safety.

A study by AAA found that the average cost of transmission repairs can range from $1,800 to $4,500. Regular maintenance and early action can help to prevent costly repairs.

Frequently Asked Questions

Question: What does the MIL light mean?

Answer: The MIL, or check engine light, is a warning signal. It means your car’s computer has detected a problem that may need attention.

Question: What should I do if the MIL light comes on?

Answer: It’s important to get the problem checked out as soon as possible. Use a scan tool to read the diagnostic trouble codes (DTCs) and determine the issue.

Question: Can I drive my car with the check engine light on?

Answer: It depends on the problem. If the light is on but your car seems to be driving normally, you can drive it for a short time. However, get it checked out quickly. If your car is having trouble, you should not drive it.

Question: How can I tell if the problem is with the transmission?

Answer: If you notice problems with gear shifting, or see the check engine light with a related code, it is most likely a transmission problem.

Question: Is it safe to fix the transmission myself?

Answer: Some minor issues can be fixed at home. For more complex problems, it’s best to seek help from a professional mechanic.

Final Thoughts

The Fix Transmission Control System MIL Request: Easy Guide breaks down the steps to identify and potentially address the issue. You learned that the check engine light, when it’s related to the transmission, can signal various issues. You saw how to use a scan tool to find the codes and understand the problem. You also explored the common causes, like sensor failures, wiring problems, and fluid issues. We covered when it’s best to attempt repairs yourself and when you need a mechanic’s expertise. Having a good knowledge of these things will keep your car running correctly.

Remember, regular maintenance, quick action, and knowing when to ask for help will keep your car going strong. Get familiar with your car’s systems, and don’t delay addressing any problems. This way, you can keep your car and your driving experience trouble-free.