Are carbon fiber brake pads good? Yes, for specific high-performance driving, carbon fiber brake pads offer superior heat resistance and longevity, but for daily driving, standard ceramic or semi-metallic pads are usually a better, more cost-effective choice. They shine where heat management is critical.

Are Carbon Fiber Brake Pads Good? Understanding the Proven Edge for Your Brakes

When you hit the brakes, you want instant, reliable stopping power. If you’ve ever looked into upgrading your car’s parts, you’ve likely seen “carbon fiber brake pads” mentioned. It sounds high-tech, but what does it actually mean for your daily commute?

Choosing the right brake pads can feel confusing. You need something safe, something that lasts, and something that won’t cost a fortune. Many drivers wonder if these fancy carbon pads are worth the hype or if they’re just for race cars. Don’t worry!

We are going to break down exactly what carbon fiber brake pads are, how they work differently, and who truly benefits from them. By the end of this guide, you’ll know if they are the right “proven edge” for your vehicle. Let’s get those brakes feeling confident!

What Exactly Are Carbon Fiber Brake Pads?

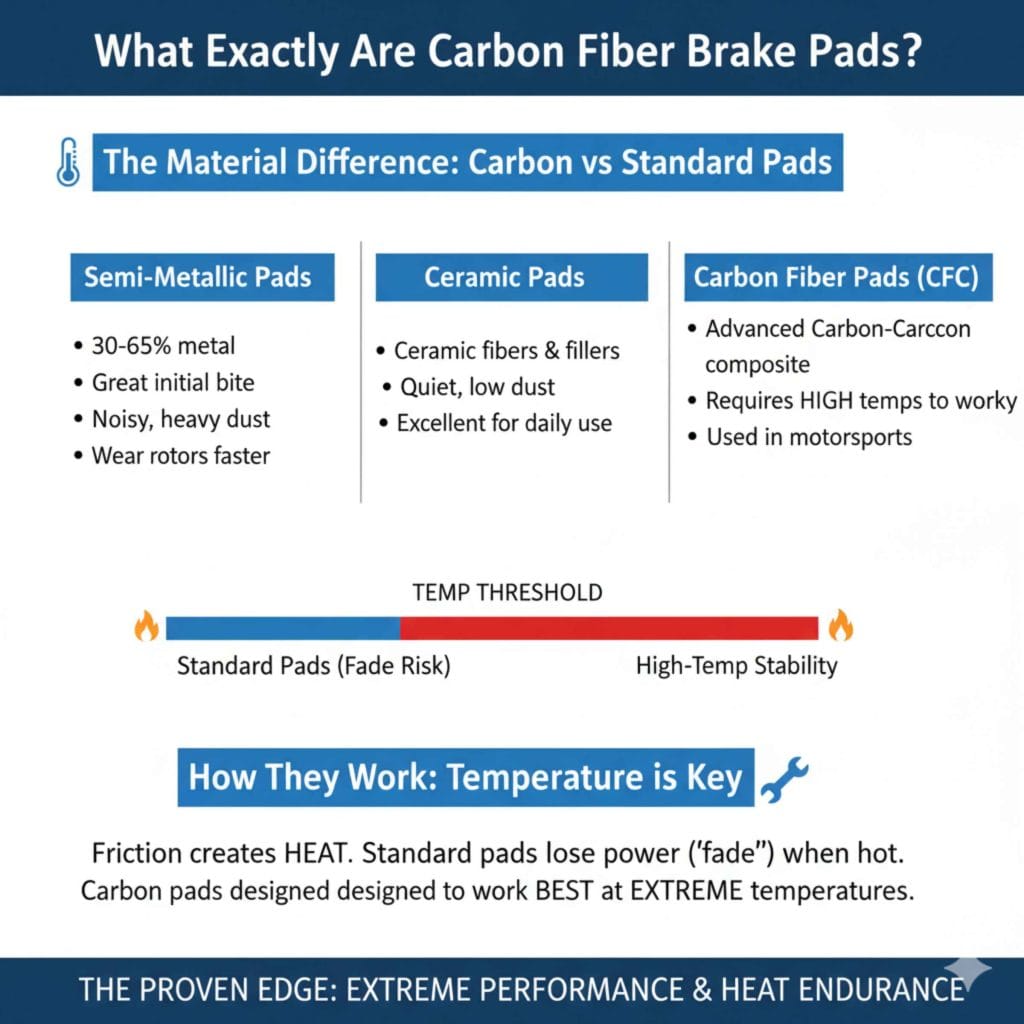

To understand carbon fiber brake pads, we first need a quick reminder of what standard pads are made of. Most pads you use every day are either semi-metallic (good stopping power, creates dust) or ceramic (quiet, low dust, consistent). Carbon fiber pads are a different breed.

These pads are usually made from a Carbon-Carbon (C-C) composite material, often referred to as Carbon Fiber Reinforced Carbon (CFC). Think of it like this: they embed extremely durable carbon fibers into a carbon matrix. This structure makes them incredibly light yet strong enough to handle extreme temperatures.

The Material Difference: Carbon vs. Standard Pads

The key difference lies in the temperature threshold. When you brake hard, friction creates heat. Too much heat, and regular pads can “fade” (lose stopping power) because the material begins to change chemically—this is called glazing or off-gassing.

Carbon fiber materials are designed to operate effectively—and not break down—at temperatures that would instantly melt or destroy standard brake rotors and pads. This high-temperature stability is their greatest advantage.

Here are the basic components you are usually comparing:

- Semi-Metallic Pads: 30% to 65% metal (like steel, iron, or copper). Great initial bite, noisy, heavy dust, wear rotors faster.

- Ceramic Pads: Ceramic fibers mixed with non-ferrous fillers. Quiet, low dust, excellent for daily street driving.

- Carbon Fiber Pads (CFC): Advanced material requiring extremely high operating temperatures to work best. Used primarily in motorsports.

The Proven Edge: Advantages of Carbon Fiber Brake Pads

When we talk about the “proven edge” of carbon fiber, we are talking about performance in extreme situations. These pads aren’t just better at stopping; they handle stress differently.

1. Unmatched Thermal Stability (No Fade)

This is the biggest selling point. Because carbon brake systems can withstand thousands of degrees Fahrenheit, they rarely experience brake fade, even after repeated, heavy braking from high speeds. This reliability means your braking distance stays consistent whether you are on your tenth stop or your first.

2. Lightweight Construction

While the brakes themselves are part of the ‘unsprung weight’ (weight not supported by the suspension), lighter components allow your suspension to react faster to the road surface. For performance driving, reducing any weight here is a major benefit.

3. Exceptionally Long Life (Under Load)

If you are applying the kind of heat and pressure that quickly destroys regular pads, carbon fiber pads often last much, much longer because the material itself is more resistant to wear and tear at those critical temperatures.

Table 1: Comparing Performance Metrics

| Attribute | Semi-Metallic | Ceramic | Carbon Fiber |

|---|---|---|---|

| Heat Tolerance | Low to Moderate | Moderate | Extremely High |

| Brake Fade Risk | Moderate (at high temps) | Low | Negligible |

| Cold Performance | Good | Good | Poor to Fair (Needs Heat) |

| Cost | Low | Medium | Very High |

| Typical Application | Daily Driving, Trucks | Daily Driving, Luxury Cars | Racing, Aviation, Heavy Industrial |

The Catch: Disadvantages for the Everyday Driver

If carbon fiber pads are so amazing, why doesn’t every new car come with them? The answer lies in their performance characteristics when they aren’t being pushed to their limits—which is most of the time for the average driver.

1. They Require Heat to Work

This is the defining weakness for street use. Carbon fiber friction materials generally need to reach a high operating temperature (often several hundred degrees) before they start gripping effectively. In cold weather or during gentle city driving (stop-and-go traffic), they feel spongy, grabby, or simply don’t stop the car as well as standard pads when cold. You need to warm them up first!

2. Sky-High Cost

The materials and manufacturing processes required for quality carbon fiber brake systems are incredibly expensive. We aren’t talking about a small upgrade fee; we are talking about potentially thousands of dollars for a full set of pads and matching rotors.

3. Rotor Incompatibility (They Need Carbon Rotors)

You cannot simply bolt carbon fiber brake pads onto your existing cast-iron brake rotors. Carbon pads wear iron rotors down incredibly fast, especially when cold. To get the benefit, you typically need to convert the entire system to a Carbon-Ceramic Matrix (CCM) rotor setup, which significantly increases the cost and complexity.

4. Wear on Cold Brakes

When cool, carbon fiber pads can be quite abrasive against standard iron rotors. This leads to premature wear on the rotors and can cause annoying squealing or grinding noises during your morning drive to work.

Who Should Consider Carbon Fiber Brakes?

Understanding the requirements helps us define the ideal user. If you fit into any of these categories, the upfront cost might be justified by the performance gain and safety factor:

- Track Day Enthusiasts: Drivers who regularly participate in high-speed road course driving where sustained, heavy braking is the norm.

- High-Performance Exotic Owners: Owners of Porsches, Ferraris, or high-end European models who track their cars occasionally and need maximum fade resistance.

- Heavy/Towing Vehicles (Specialty Use): While less common, specialized heavy-duty applications that frequently deal with extreme load and heat might benefit from this extreme thermal resistance, though industrial-grade ceramic/metallic composites are more often used here.

If you drive locally, commute mostly on highways, or treat spirited driving as an occasional event, carbon fiber pads are generally overkill. You will be paying a premium for performance you won’t use, and you might actually compromise your cold-weather braking performance. For more general information on brake safety and material science, consulting resources like the National Highway Traffic Safety Administration (NHTSA) can help ground your maintenance decisions in official safety standards.

The Best Alternatives for Daily Drivers (The Smart Upgrade)

For 95% of drivers, the goal is reliable, quiet stopping without the racing expense. The sweet spot for performance and practicality usually lies with high-quality ceramic or performance semi-metallic pads.

Option A: Premium Ceramic Pads

Modern premium ceramic pads behave much like the old standard ones but with better temperature control. They are fantastic because they produce very little dust, last a long time, and remain quiet.

- Pros: Quiet, low dust, great for daily commutes, consistent performance down to lower speeds.

- Cons: Initial “bite” can feel slightly softer than metallic pads.

Option B: Performance Semi-Metallic Pads

These are perfect if you like a very firm, immediate feel when you touch the pedal, often called a great “initial bite.” They perform well even when cold.

- Pros: Excellent stopping power right away, great pedal feel, often better in wet conditions.

- Cons: Generate more brake dust (those black streaks on your wheels), may be slightly noisier, and wear rotors slightly faster than ceramics.

Choosing Your Upgrade Path

Think about how you drive 90% of the time. If you’re quiet city driving, choose Ceramic. If you enjoy aggressive street driving but don’t hit the track, choose Performance Semi-Metallic. Save the Carbon Fiber discussion for when you buy your first race car!

Installation Considerations: Why Carbon Brakes Are Not DIY-Friendly

Even if you decide you need carbon brakes, understanding the installation process is crucial. Unlike standard brake pad swaps, installing a full Carbon-Ceramic Matrix (CCM) brake system is advanced maintenance that should often be left to professionals.

The Tool and System Requirements

Switching fully to a carbon system involves changing the rotors, calipers, and sometimes even specialized brake fluid designed to handle the high temperatures generated by the carbon components. Professional shops have the specialized tools and diagnostic equipment to ensure everything is bedded in correctly.

The crucial step here is “bedding in.” This process mates the new pad material perfectly to the new rotor surface. Failing to bed in high-performance pads correctly can lead to irreversible glazing or hot spots, instantly ruining the expensive components.

If you are comfortable changing standard pads yourself, you can likely handle high-quality ceramic replacements. However, if you are crossing over to a full carbon system, your peace of mind (and safety) is worth paying a professional mechanic. Safety in braking systems is non-negotiable; remember to always prioritize secure installation over saving a few dollars.

Maintenance Tips for High-Performance Brake Components

Once you have invested in real performance brakes (be they carbon or high-end ceramic/metallic), proper care will maximize their life and performance. Treat them right, and they will stop you safely for years.

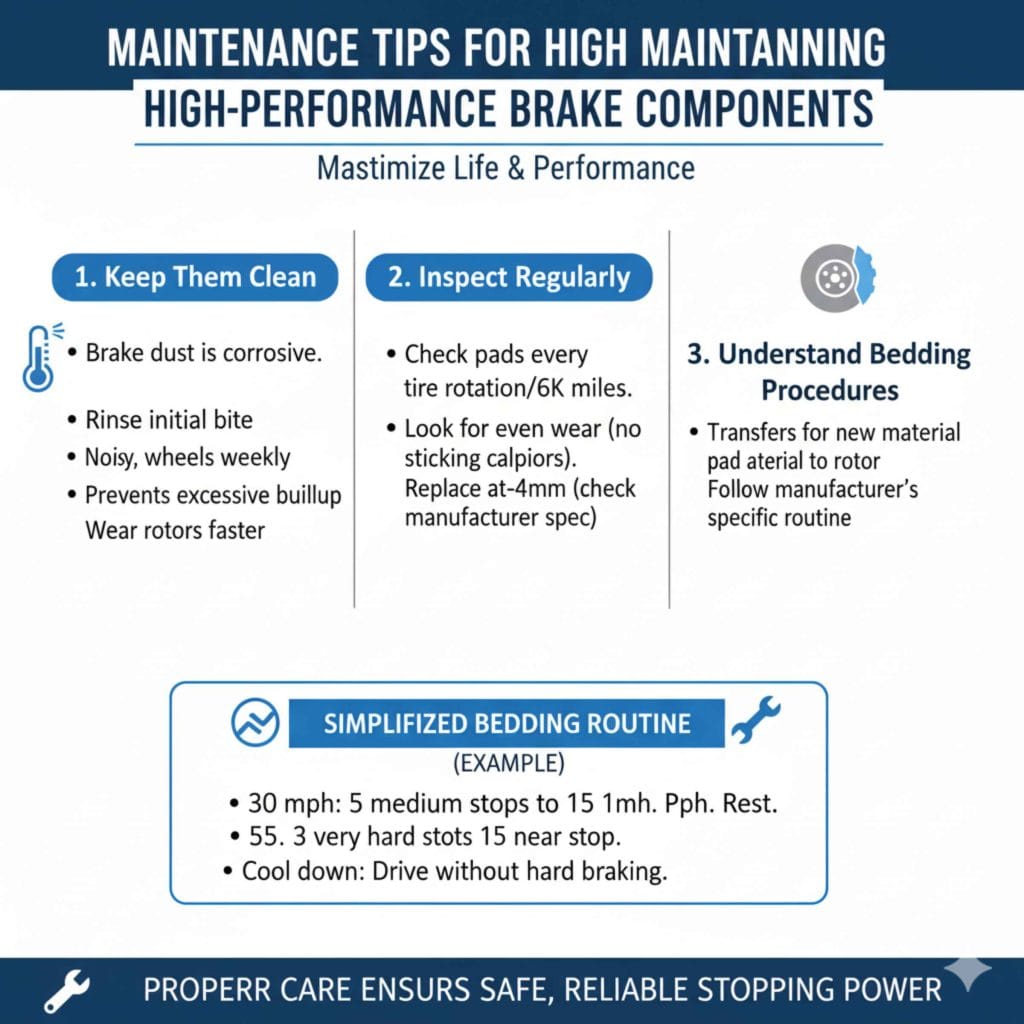

1. Keep Them Clean (Especially the Dust)

Brake dust is corrosive. If you have semi-metallic pads, the dust sticks to the wheel finish. If you have high-performance pads, debris from aggressive driving can accumulate. A weekly rinse of the wheels helps prevent excessive buildup.

2. Inspect Regularly

You should check your brake pads every time you rotate your tires (or every 6,000 miles). Look for an even wear pattern. If one pad is wearing faster than the other, it can indicate a sticking caliper slider pin, which needs lubrication or replacement. Brake pads should generally be replaced when they reach 3 or 4mm remaining thickness, though always check the manufacturer’s recommendation.

3. Understand Bedding Procedures

Whether you install standard performance pads or carbon ones, following the manufacturer’s bedding-in procedure is essential. This usually involves a series of controlled speed increases and medium-to-hard stops to transfer a layer of pad material onto the rotor surface evenly.

Here is a simplified example of a bedding routine (Always use the specific instructions provided by your pad manufacturer):

- Drive at 30 mph. Make 5 medium stops (about 50% effort) down to 10 mph. Rest briefly.

- Drive at 45 mph. Make 5 hard stops (about 75% effort) down to 15 mph. Rest briefly.

- Drive at 55 mph. Make 3 very hard stops (about 90% effort) down to a near stop. This generates significant heat.

- Drive normally for several miles without braking hard to allow the brakes to cool down slowly.

This controlled heating and cooling ensures the friction compound bonds correctly with the rotor, providing reliable and consistent stopping power when you need it most.

Frequently Asked Questions (FAQ) About Carbon Fiber Brakes

Q1: Will carbon fiber brake pads destroy my regular street car rotors?

A: Yes, very quickly. Carbon fiber pads are designed to mate with specialized Carbon-Ceramic (CCM) rotors. Putting them on standard iron rotors will result in rapid, uneven wear and potential rotor damage, especially when the pads are cold.

Q2: Are carbon fiber brake pads safe for driving in the rain?

A: When cold, they perform poorly in the rain. Once up to operating temperature, they handle water well because the heat boils off surface moisture. However, for general street driving, ceramic pads offer more reliable performance when the brakes are naturally cold and wet.

Q3: How much more expensive are carbon fiber brakes compared to ceramic?

A: The difference is huge. A set of performance ceramic pads might cost $150–$300. A full carbon fiber brake system (pads and rotors) can easily cost $5,000 to $15,000 or more, depending on the vehicle and system complexity.

Q4: Can I use carbon fiber brake pads for everyday street driving?

A: Technically, yes, but it’s impractical. They squeal when cold, don’t grip well below temperature, and wear out incredibly fast if you aren’t constantly pushing heat into them, making them a poor choice for commuting.

Q5: Does carbon fiber mean carbon ceramic brakes?

A: They are closely related, but not always the same. High-end factory performance brakes (like Porsche PCCB) are Carbon Ceramic Matrix (CCM). Carbon fiber pads are one component used in some extreme applications, often working with ceramic discs.

Q6: If I upgrade my pads, do I have to upgrade my rotors too?

A: If you upgrade to carbon fiber or true carbon ceramic pads, yes, you must upgrade the rotors. If you upgrade to a high-temperature ceramic or performance semi-metallic pad, you can usually use your existing standard rotors, provided they are in good condition.

Conclusion: Making the Smart Choice for Your Brakes

So, are carbon fiber brake pads good? They are absolutely fantastic—for the specific, high-stress environment they were designed for. They represent the peak of friction material technology when dealing with immense heat and require repeated, heavy braking.

However, for the vast majority of drivers who rely on their cars for commuting, errands, and the occasional spirited backroad blast, the disadvantages of inconsistent cold-weather performance and astronomical cost simply don’t justify the investment. It’s like putting a jet engine on a lawnmower.

Your true “proven edge” for everyday safety, reliability, and peace of mind lies in selecting high-quality, application-specific pads—either premium ceramics for low dust and quiet operation or performance semi-metallics for maximum initial grab. By sticking to proven, street-engineered materials, you ensure your braking system performs perfectly every single time you press the pedal, keeping your car safe and your wallet happy.