No, not all NASCAR engines are the same. While they must follow extremely strict rules on size, design, and parts, each of the three manufacturers—Chevrolet, Ford, and Toyota—designs and builds its own unique engine. The small, subtle differences they create within the rules are where teams find their winning edge on the track.

Have you ever watched a NASCAR race and been mesmerized by the thunderous roar of 40 cars speeding past? It’s an incredible sound. As they fly by in a blur, it’s easy to think they’re all identical machines. After all, they look similar and sound similar. This leads to a great question I hear all the time: are the engines under the hood all the same?

It’s a perfectly logical question. The cars are built to be as equal as possible to make the racing fair and exciting. But the truth about the engines is one of the most fascinating parts of the sport. The answer isn’t a simple yes or no. In this guide, I’ll break down exactly what makes these powerhouses similar, what makes them shockingly different, and how those tiny differences can mean winning or losing a championship.

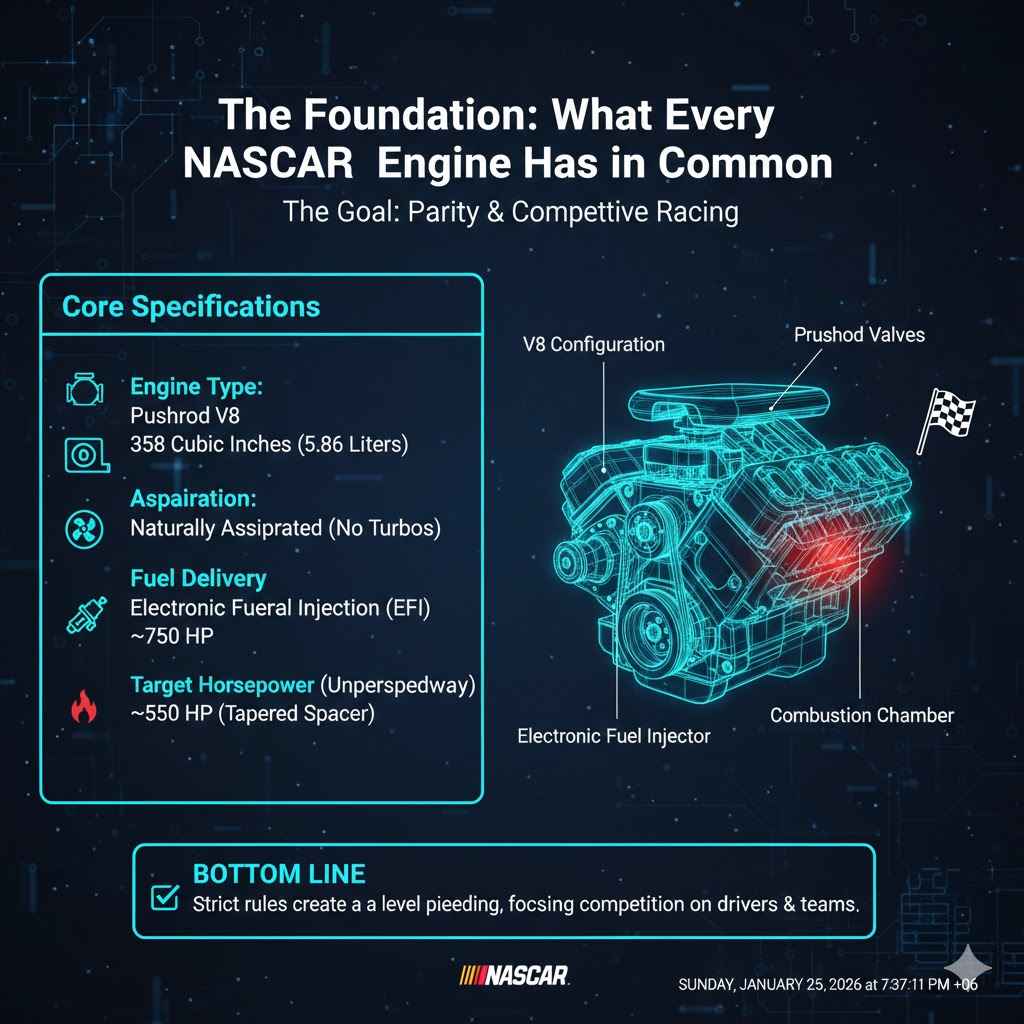

The Foundation: What Every NASCAR Engine Has in Common

Before we dive into the differences, we have to start with the rulebook. NASCAR has a very thick book of rules that every team must follow. The goal is to create a level playing field, ensuring that no single team or manufacturer can create an engine that’s wildly more powerful than anyone else’s. This is called “parity,” and it’s what makes the racing so close and competitive.

Think of it like a baking competition where every chef is given the same list of basic ingredients and the same oven temperature. They all have to start from the same place. For NASCAR engines, these “basic ingredients” are a set of strict specifications. Here’s what every single Cup Series engine has in common:

- Engine Type: They are all naturally aspirated, pushrod V8 engines. Let’s break that down. “V8” means there are eight cylinders arranged in a V-shape. “Naturally aspirated” means the engine breathes air normally, without the help of a turbocharger or supercharger that would force more air in. “Pushrod” refers to an old-school, reliable way the engine’s valves open and close.

- Displacement: Every engine must be exactly 358 cubic inches, which is about 5.86 liters. To put that in perspective, the engine in a popular family sedan like a Toyota Camry is usually around 2.5 liters. So, a NASCAR engine is more than twice as big!

- Fuel System: Since 2012, all engines use Electronic Port Fuel Injection (EFI). This is a modern, computer-controlled system that delivers fuel to each cylinder precisely. It replaced the old-school carburetors and made the engines more efficient and reliable.

- Horsepower Targets: This is a big one. NASCAR changes the horsepower depending on the type of track to control speeds and improve safety. For most tracks (short tracks and intermediate ovals), the engines produce around 750 horsepower. For the giant superspeedways like Daytona and Talladega, a part called a “tapered spacer” is used to restrict airflow, cutting the power down to about 550 horsepower.

These rules create a very specific “box” that all three manufacturers must build their engines inside. Here’s a quick look at those core specs.

| Specification | NASCAR Cup Series Requirement |

|---|---|

| Engine Configuration | Pushrod V8 |

| Displacement | 358 Cubic Inches (5.86 Liters) |

| Aspiration | Naturally Aspirated (No Turbos) |

| Fuel Delivery | Electronic Fuel Injection (EFI) |

| Target Horsepower (Unrestricted) | ~750 HP |

| Target Horsepower (Superspeedway) | ~550 HP |

The “Big Three”: Where the Differences Lie

Okay, so if the rules are so strict, how can the engines be different? This is where the real magic happens. Within that tight rulebook, the three official manufacturers in the Cup Series—Chevrolet, Ford, and Toyota—have room to innovate.

Each manufacturer designs its own unique engine. They don’t share blueprints or secrets. They each have a dedicated engineering team and a partner engine builder responsible for creating their contender.

- Chevrolet: Their engine is the R07, primarily built by Hendrick Motorsports and ECR Engines.

- Ford: Their engine is the FR9, built exclusively by the masterminds at Roush Yates Engines.

- Toyota: Their engine is the TRD (Toyota Racing Development) engine, built in-house by TRD’s U.S. operations.

So, what parts are they actually designing differently? The competition happens in the tiny details that aren’t completely locked down by the rules. The main battlegrounds are:

1. Cylinder Head Design

The cylinder head sits on top of the engine block and controls how air and fuel get into the cylinders and how exhaust gets out. Think of it as the engine’s lungs. The shape and design of the “ports” (the passages for air and exhaust) are critical. A better-designed port can help the engine breathe more efficiently, which translates directly into more horsepower. Manufacturers spend millions of dollars in research and development to find the perfect shape for these ports while still staying within NASCAR’s rules for dimensions and angles.

2. Internal Component Engineering

While NASCAR specifies the exact size of many internal parts like the pistons and crankshaft, the manufacturers can still play with the fine details. They can use advanced computer modeling to design components that are lighter but just as strong. For example, they can subtly change the shape of a connecting rod or the internal structure of a piston to reduce weight. Less weight inside the engine means it can spin faster and respond more quickly, giving the driver a tiny but crucial advantage.

3. The Engine Block

The engine block is the heavy iron foundation of the engine. While its external dimensions and cylinder locations are fixed, manufacturers have some freedom in the casting process. They can adjust the thickness of certain walls or refine the passages for oil and coolant. The goal is to make the block as strong and reliable as possible while keeping it from being unnecessarily heavy. A well-designed cooling system within the block can also help the engine run at a more consistent temperature, preventing power loss over a long 500-mile race.

It’s like three different chefs baking that cake we talked about. They all have the same basic ingredients, but one might whip their eggs a little differently, another might have a secret sifting technique for their flour, and the third might have a unique way of cooling the cake. The final products will be very similar, but those subtle differences in technique are what separate a good cake from a great one.

Why Do These Tiny Differences Matter So Much?

In a sport where races are often won by thousandths of a second, even a single extra horsepower can be the difference between first and second place. This is the concept of “marginal gains”—the hunt for a tiny advantage anywhere you can find it. An engine that produces just a little more power on the straightaways, or one that is slightly more fuel-efficient, can change the outcome of a race.

Durability is another huge factor. A NASCAR engine has to survive 500 miles of brutal, high-stress conditions, running at over 9,000 RPM for hours on end. An engine that is incredibly powerful but can’t last the entire race is useless. The engine builders at Chevrolet, Ford, and Toyota are in a constant battle to create power that is also reliable.

Finally, there’s the “power band.” This refers to the range of engine speeds (RPM) where it produces the most power. Some engines might be designed to produce maximum power at the very top end, which is great for a big, fast track. Others might be tuned to have more “grunt” at lower RPMs, helping the driver accelerate out of tight corners on a short track. These subtle differences in engine character can make a car better suited for certain types of racetracks. You can learn more about how these incredible machines are put together in NASCAR’s official Next Gen car explainer, which details the new era of vehicle design.

The Role of the Engine Builder: The Unsung Heroes

The manufacturers design the engines, but they don’t assemble every single one that hits the track. That job falls to the specialized engine builders. These are high-tech facilities filled with some of the smartest engineers and mechanics in the world.

A race team like Hendrick Motorsports or Joe Gibbs Racing doesn’t just get a crate engine shipped from a factory. Their engines are hand-built by their dedicated engine shop with an incredible level of precision. Here’s what these engine builders do:

- Precision Assembly: They assemble each engine by hand in sterile, climate-controlled rooms. Every single bolt is tightened to an exact specification, and every measurement is checked and double-checked.

- Dyno Testing: Before an engine ever goes into a race car, it’s put on a dynamometer, or “dyno.” This machine measures the engine’s horsepower and torque output across its entire RPM range. The builders run the engine through a simulation of the upcoming race to ensure it can perform perfectly and withstand the stress.

- Finding Improvements: The engine builders are also on the front lines of development. They work closely with the manufacturers, providing feedback from the dyno and the track to help improve the next generation of engine designs.

- Maintenance and Rebuilds: A NASCAR engine is only used for one race weekend. After the race, it’s sent back to the shop, completely disassembled, inspected, cleaned, and rebuilt with many new parts. This ensures maximum performance and reliability for the next race.

The engine builders are the vital link between the manufacturer’s design and the on-track performance. Their skill and attention to detail are just as important as the original design itself.

A Look at the Past vs. Present: How Things Have Changed

NASCAR engines haven’t always been this specialized. In the early days, the “stock” in “stock car racing” meant something. The engines were much closer to what you could find in a passenger car on the showroom floor. Over the decades, as the sport became more competitive and professional, the engines evolved into the purpose-built racing machines they are today.

One of the biggest changes was the switch from carburetors to Electronic Fuel Injection (EFI) in 2012. Carburetors were mechanical devices that mixed air and fuel. They were simple but could be finicky and less efficient. EFI uses computer sensors and injectors to deliver fuel much more precisely. This move was a huge step in modernizing the sport, bringing the technology closer to what is used in modern street cars. To see just how far things have come, this helpful article from HowStuffWorks provides a great deep dive into the engineering.

Let’s compare a classic NASCAR engine from the 1970s to a modern one.

| Feature | 1970s NASCAR Engine | Modern NASCAR Engine |

|---|---|---|

| Fuel System | Carburetor | Electronic Fuel Injection (EFI) |

| Horsepower | ~600 HP | ~750 HP (Unrestricted) |

| Lifespan | Often rebuilt after every race | Used for one race, then completely rebuilt |

| Key Materials | Cast Iron Block and Heads | Compacted Graphite Iron Block, Aluminum Heads |

| Data & Electronics | Minimal (Tachometer, Gauges) | Advanced ECU with dozens of sensors |

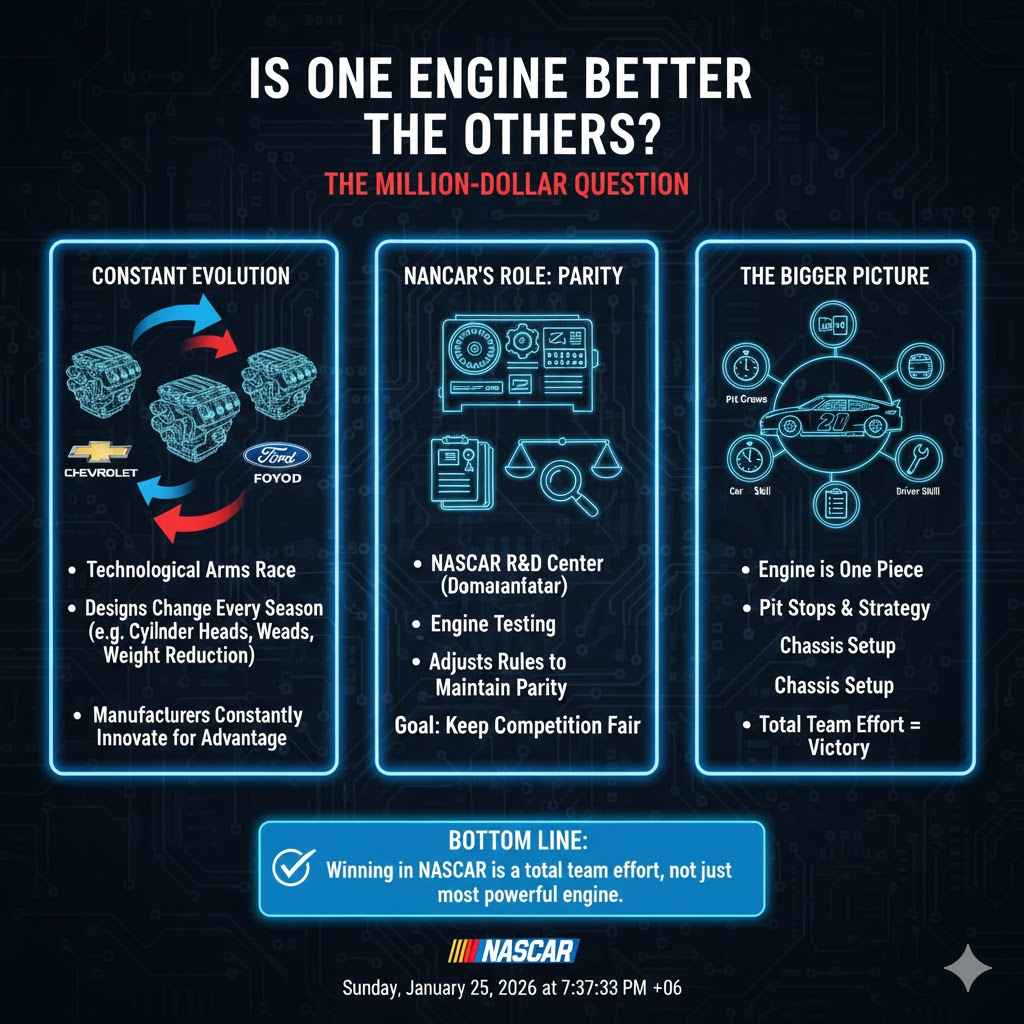

So, Is One Engine Better Than the Others?

This is the million-dollar question for every race fan. Is the Chevy, Ford, or Toyota engine the best? The truth is, it changes all the time. The manufacturers are in a constant technological arms race. One season, Toyota might introduce a new cylinder head design that gives them a slight edge. The next year, Ford might respond with a lighter set of internal components that levels the playing field.

NASCAR also plays an active role in keeping things fair. They have their own research and development center where they can test engines from all three manufacturers on a dyno. If they find that one manufacturer has developed a significant advantage, they may adjust the rules to bring the others back into contention. Their goal is always to ensure the competition is about the drivers, the pit crews, and the car setups—not just about which team has the most powerful engine.

At the end of the day, the engine is just one piece of a very complex puzzle. A team can have the most powerful engine on the track, but it won’t matter if they have a bad pit stop, the wrong car setup, or if the driver makes a mistake. Winning in NASCAR is a total team effort.

Frequently Asked Questions (FAQ)

How much does a NASCAR engine cost?

A single NASCAR Cup Series engine is an incredibly complex piece of machinery, and its price reflects that. While teams don’t publish exact figures, it is widely understood that a complete, race-ready engine costs upwards of $100,000 to build.

Can you buy a NASCAR engine for a street car?

Technically, yes, you could buy a used one from a race team or builder, but it would be extremely impractical for a street car. These engines are designed to run at full throttle for a few hours and then be rebuilt. They require specialized racing fuel, have no accessories for things like air conditioning, and would be terrible in stop-and-go traffic.

How long does a NASCAR engine last?

A NASCAR engine is built to last for just one race weekend, which includes practice, qualifying, and the race itself—typically around 500 to 600 miles. After the race, it is sent back to the engine shop to be completely disassembled, inspected, and rebuilt with many new parts before its next use.

Do all cars from the same manufacturer (e.g., all Fords) have the exact same engine?

Yes, for the most part. All Ford teams, for example, get their engines from the same builder (Roush Yates Engines). These engines are built to be as identical as possible to ensure fairness and consistency across all the teams running that manufacturer’s car.

What kind of fuel do NASCAR engines use?

NASCAR cars use a special racing fuel supplied by Sunoco called Green E15. It is a 98-octane fuel blended with 15% ethanol. It’s engineered specifically for the high-compression, high-RPM environment of a racing engine.

Why don’t they use turbochargers like in other racing series?

The use of naturally aspirated V8 engines is a core part of NASCAR’s identity and tradition. It creates a unique sound and style of racing that focuses on raw, unassisted power. The rules have been built around this specific engine formula for decades to maintain the sport’s character.

Are the engines the same for all three NASCAR series (Cup, Xfinity, Trucks)?

No, they are not. Each of NASCAR’s top three national series has its own set of engine rules. The Cup Series engines are the most powerful and technologically advanced. The Xfinity Series and Craftsman Truck Series use different engines with lower horsepower targets to match the characteristics of their respective vehicles and series.

Conclusion: A Symphony of Precision

So, are all NASCAR engines the same? As you can see now, the answer is a definite “no.” While they are born from the same strict set of rules, they are more like brothers than identical twins. Each one—the Chevrolet R07, the Ford FR9, and the Toyota TRD—has its own unique personality, engineered in a secret battle of wits and technology fought by some of the brightest minds in motorsports.

The rules ensure the competition is close, but the freedom within those rules allows for the innovation that defines the sport. It’s a beautiful balance that makes every race unpredictable. The next time you’re watching a race and you hear that incredible roar, listen a little closer. You’re not just hearing raw power; you’re hearing the result of thousands of hours of design, engineering, and passion. You’re hearing a symphony where three different masters are all trying to play the same tune, just a little bit faster, a little bit stronger, and a little bit better than the rest.