Quick Summary: No, not all NASCAR engines are the same, though they must meet strict current rules for the Cup Series, primarily using a naturally aspirated, 5.8-liter V8 engine. Different NASCAR series (like Xfinity and Trucks) use specific, tailored engines focusing on parity and safety.

Are All NASCAR Engines The Same? Proven Power Unpacked

Ever watched a NASCAR race and wondered if every speeding machine on the track has the exact same heart beating under the hood? It’s a super common question! Looking at those roaring stock cars, it’s easy to assume they are mechanically identical, especially when they stick so close together at 200 mph. That strong sense of parity—that feeling that every driver has an equal shot—is a huge part of what makes racing exciting. But the truth behind are all NASCAR engines the same is a little more detailed, depending on which level of racing you are watching. We are going to break down the powerful V8s that make NASCAR famous. We’ll keep it simple, ditch the complicated jargon, and get you feeling confident about what powers these incredible machines. Let’s dive into the mechanics that define NASCAR power!

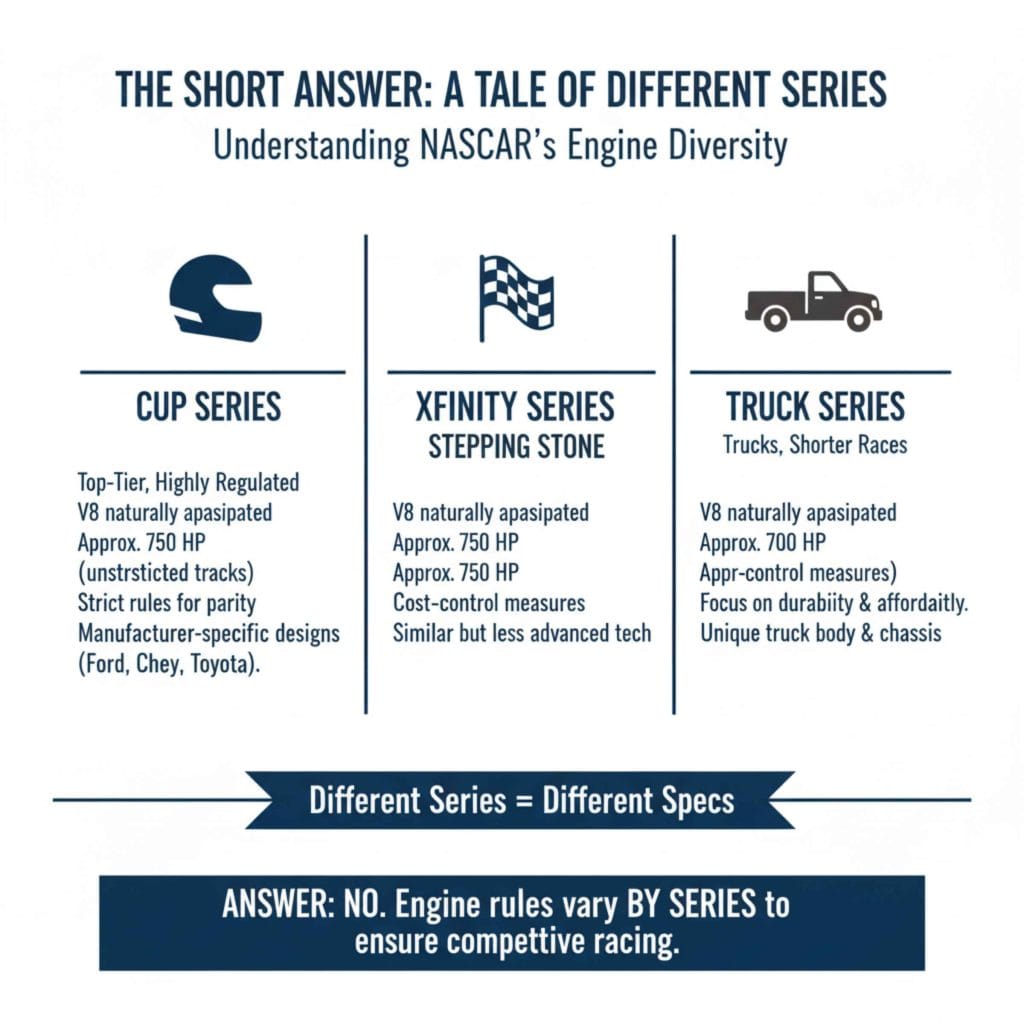

The Short Answer: A Tale of Different Series

To give you the clearest picture right away, the answer to whether all NASCAR engines are the same depends entirely on which NASCAR series you are focusing on. If you are watching the top-tier Cup Series, their engines are highly regulated to ensure a level playing field. However, if you look down the ladder at the Xfinity Series or the Truck Series, you will find different engine specifications designed for those specific classes. Understanding these differences helps explain why the racing looks, sounds, and performs slightly differently across the board.

Deconstructing the NASCAR Cup Series Engine

The Cup Series is the elite level of NASCAR. Here, the engines are designed for maximum power output while adhering to incredibly tight rules set by NASCAR. The goal isn’t to let teams build the fastest engine possible; the goal is to let the best teams win by building the best legal engine.

The Heart of the Beast: The V8 Standard

For decades, the foundation of NASCAR power has been the V8 engine. This setup is non-negotiable in the Cup Series because of historical tradition and the sheer power characteristics it provides.

Key V8 Specifications (Current Generation):

Type: Naturally Aspirated V8 (meaning no turbochargers or superchargers are allowed).

Displacement: Limited to 358 cubic inches (about 5.8 liters). This displacement limit is crucial for parity.

Fuel: They run on Sunoco Racing Fuel (an E15 blend, which is 15% ethanol content). This specialized fuel is engineered for high-performance, high-compression racing.

Horsepower: While the exact figures are closely guarded secrets and can slightly change based on track configuration (like plate vs. non-plate tracks), these engines generally produce between 670 and 750 horsepower.

Torque: They produce massive amounts of torque, necessary to push these heavy stock cars to speeds well over 200 mph.

The Evolution: From Carburetors to Fuel Injection

One major factor that separates older engines from the current ones is how fuel gets into the cylinders.

For many years, NASCAR used carburetors, which are mechanical devices that mix air and fuel. This system was simpler but less precise. In 2012, NASCAR mandated a switch to electronic fuel injection (EFI) to improve reliability, reduce maintenance cycles, and tighten control over engine output. This change was a big step toward modernizing the sport while maintaining the V8 architecture.

A key component of the modern Cup Series engine package, especially crucial for safety and regulation, is the mandated use of the “spec” (standardized) components. While teams build their own engines, they must use parts sourced in a way that minimizes performance gaps between the major manufacturers (Ford, Chevrolet, Toyota).

Comparing NASCAR Series Engines

When you ask if are all NASCAR engines the same, you have to look beyond just the Cup Series. The ladder system—from the entry-level series up to the top tier—uses engines specifically designed for their respective series needs, often prioritizing durability and cost control over peak horsepower.

NASCAR Xfinity Series Engines

The Xfinity Series (the second-highest level) used to feature older-spec Cup Series engines. However, in recent years, NASCAR has implemented new engine packages aimed at reducing operational costs for teams.

The Xfinity Series now relies heavily on standardized components, sometimes referred to as “Generation 4” or cost-effective blueprints. While still V8s, they generally produce less peak power than the Cup engines. This slight drop in power helps emphasize driver skill in handling the cars, which sometimes are slightly lighter or have different aerodynamic platforms than the Cup cars.

NASCAR Craftsman Truck Series Engines

The Truck Series is the developmental ground for NASCAR. Its engines are designed to be rugged, reliable, and relatively affordable to maintain.

These trucks historically used purpose-built V8 engines, but this series has also undergone significant specification changes. Currently, the series uses a high-performance, sealed V8 or, in some cases, engines that share more components across the board. The focus here is on durability and making sure teams can race hard without needing constant, extremely expensive engine rebuilds, which is vital for smaller teams.

Table 1: Comparison of Core NASCAR Engine Philosophies

This table summarizes the general design intent for the engines you see across the top three national series.

| Series Level | Primary Engine Goal | Typical Horsepower Range (Estimate) | Level of Standardization |

|---|---|---|---|

| Cup Series | Peak speed and ultimate performance under strict parity rules | 670–750 HP | High regulations, team-built blocks |

| Xfinity Series | Balancing performance with cost control and driver development | 600–650 HP | Increased use of standardized parts |

| Truck Series | Durability, affordability, and close racing | 500–600 HP | Very high standardization, focused on longevity |

Beyond the Basics: What Makes a NASCAR Engine Unique?

A NASCAR engine isn’t just a souped-up street car engine. Every element is specialized for the unique stresses of sustained, high-RPM competition. If you’ve ever worked on a daily driver, you’ll notice some huge differences when looking at NASCAR powerplants.

1. Dry Sump Oil System

A standard car uses a wet oil sump—the oil pan sits at the bottom of the engine and collects oil. At the high G-forces experienced in banked turns, the oil can slosh away from the pickup tube, starving the engine of lubrication and causing instant failure.

NASCAR engines use a dry sump system. This is an external system where oil is actively pumped out of the oil pan and stored in a separate reservoir. Scavenger pumps then continuously return the oil to the engine. This guarantees oil flow even when the car is sideways or pulling massive lateral G-forces. This is non-negotiable for track performance.

2. Extreme High-Revving Capability

Your typical passenger car engine redlines around 6,000 to 7,000 RPM. Cup Series engines are regularly pushed to 9,000 RPM or even slightly above for short bursts. This requires specialized materials that can withstand incredible rotational forces.

This means components like connecting rods, crankshafts, and pistons must be forged from the strongest, lightest alloys available that still fit within NASCAR’s strict rulebook. If you want to learn more about the importance of standardized parts in racing, the official NASCAR resources often discuss their safety and parity guidelines.

3. Built for Endurance, Not Mileage

While street engines are built for hundreds of thousands of miles, NASCAR engines are built for intense, sustained power over a few hundred miles. They are essentially treated as disposable assets that must perform perfectly until their scheduled replacement.

Most Cup Series engines are designed to last about 600–700 miles before being rebuilt or rotated out. This allows teams to run them right on the absolute edge of mechanical failure without worry, knowing they will be refreshed soon after. Reliability is still key, but longevity past the race distance is not the primary concern.

The Role of Standardization and Parity (Why They Try to Make Them the Same)

The core philosophy behind NASCAR engine regulations is parity. Parity means ensuring that the primary difference in speed comes from driver skill, crew chief strategy, and aerodynamic setup, rather than one manufacturer finding a secret engine design advantage.

To enforce this, NASCAR uses various methods, including:

- Mandating specific block casting designs.

- Controlling the use of electronic control units (ECUs).

- Requiring teams to use specific, pre-approved parts from certain suppliers or engines built to tight specifications by approved engine builders.

This creates an environment where teams can spend their technical budgets optimizing the application* of the power (like tuning, airflow management, and chassis setup) rather than engaging in an uncontrollable, multi-million-dollar arms race solely on engine architecture.

Table 2: Essential Custom Engine Components

These parts are vastly different (and often stronger) than what you find in a standard road-going vehicle engine block.

| Component | Street Car Standard | NASCAR Cup Equivalent | Why the Difference? |

|---|---|---|---|

| Pistons | Cast or Hypereutectic | Forged Aluminum or Billet | Handles extreme heat and pressure spikes at high RPM. |

| Valvetrain | Hydraulic or Solid Lifters | Solid Lifters, Roller Cams | Allows for much higher, sustained RPM reliability. |

| Cylinder Head | Standardized Porting | Highly customized and flowed ports by engine builders | Optimized for maximum airflow and combustion efficiency within rules. |

| Oil System | Wet Sump (Oil Pan) | Dry Sump (External Reservoir) | Prevents oil starvation during hard cornering (lateral G-forces). |

The Future: Introduction of the Next Gen Engine Package

NASCAR has always evolved. As of the 2022 season, the Cup Series introduced the “Next Gen” car, which brought several technological shifts, including the move to independent rear suspension and a standardized transmission. While the core V8 architecture remains, the engine package is constantly tweaked to integrate with the new chassis.

One area of ongoing discussion in the sport involves the potential introduction of hybrid components in the future. While the current engines are staying purely internal combustion for now, the overall trend in global motorsport, as seen with hybrid systems in Formula 1 or endurance racing, suggests that NASCAR will one day look at electrification to boost performance or meet environmental goals aligned with organizations like the U.S. Environmental Protection Agency’s goals for cleaner transportation technology.

For now, the V8 reigns supreme, but teams are always looking for the smallest legal edge, whether through advanced machining tolerances or better fuel mapping for the EFI system.

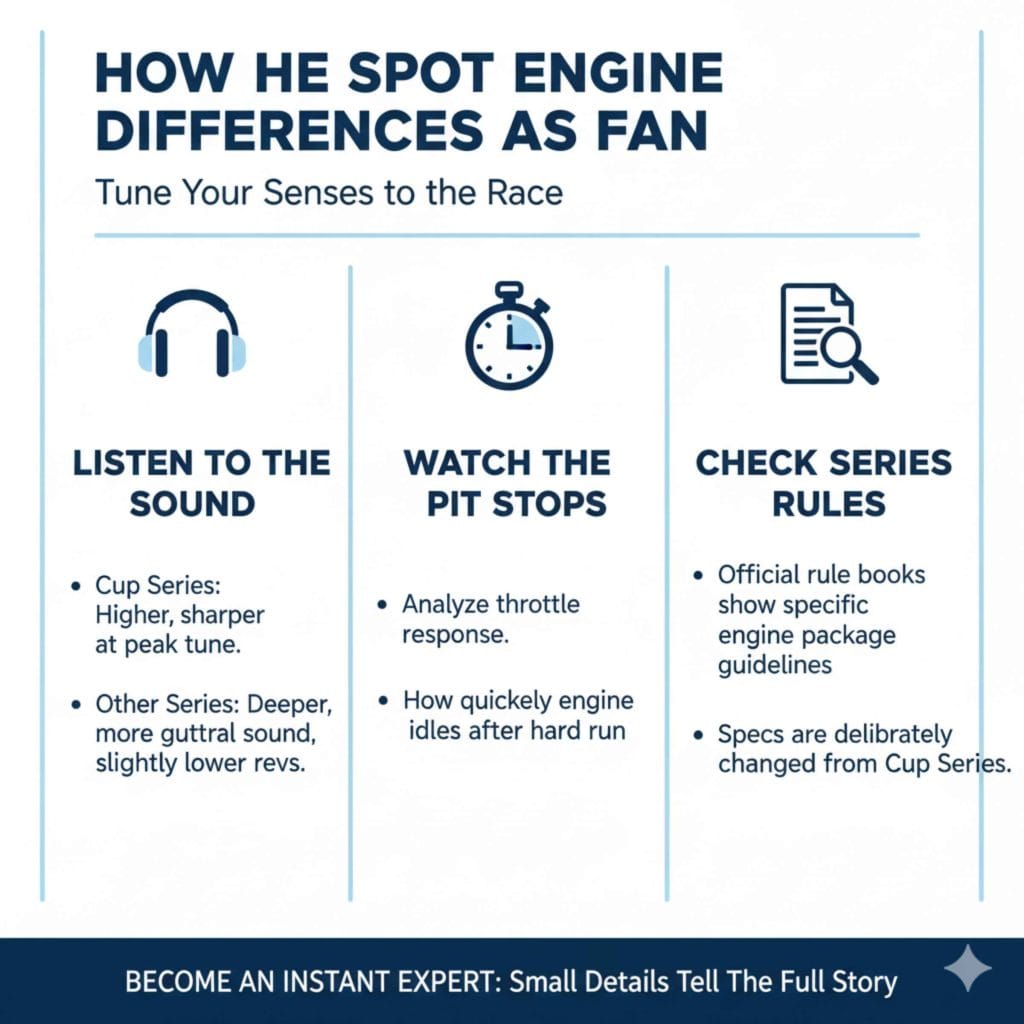

How To Spot Engine Differences as a Fan

You don’t need a degree in mechanical engineering to notice the differences between engines just by listening or watching:

- Listen to the Sound: Cup Series engines, running at peak tune, often have a higher, sharper scream compared to the slightly deeper, more guttural sound of the Xfinity or Truck Series engines, which might rev slightly lower.

- Watch the Pit Stops: Pay attention to how long the engine runs after being stressed. In tests, teams will often analyze throttle response and how quickly the engine settles back to idle after a hard run, looking for signs of superior tuning.

- Check Series Rules: If you visit the official rule book for any given weekend, you’ll see specific engine package guidelines listed for that series, confirming that the specs are deliberately lowered or changed from the Cup Series baseline.

Frequently Asked Questions (FAQ) for Beginner Fans

Q1: Are NASCAR Cup engines built by NASCAR, or by the race teams?

A: The engines are built by the race teams themselves or by specialized, approved engine shops contracted by the teams. However, NASCAR sets extremely strict blueprints and rules specifying what can and cannot be used to maintain fairness.

Q2: Why does NASCAR stick with V8 engines if other racing leagues use different types?

A: The V8 engine is deeply rooted in stock car racing history and tradition. It provides the massive low-end torque necessary for powerful acceleration in heavy stock cars, making the racing product exciting for the fans.

Q3: Do Cup Series engines sound the same, even if they are Ford, Chevy, or Toyota?

A: They sound very, very similar! Because the fundamental architecture—the 5.8-liter, naturally aspirated V8—is mandated and highly controlled, the primary sonic difference comes down to the specific exhaust header design and tuning by each manufacturer’s engine builders, but overall, they share a distinctive V8 roar.

Q4: What if a mechanic tries to cheat and put a turbocharger on the engine?

A: If a team is caught trying to use unauthorized components like a turbocharger, the penalties are severe, often including immediate disqualification from the race, hefty fines, and potential suspension for team leadership. NASCAR performs random and detailed engine teardowns (inspections) after races to prevent this.

Q5: Are the engines the same for short tracks versus superspeedways (like Daytona)?

A: No, the engines are “de-tuned” for superspeedways like Daytona and Talladega. NASCAR uses restrictor plates (or tapered spacers in the current generation) which essentially choke off the amount of air entering the engine. This limits horsepower to keep speeds safely under 200 mph on those high-speed ovals.

Q6: Is the oil used in NASCAR engines something I can buy for my car?

A: No. NASCAR exclusively uses highly specialized synthetic racing oil, such as that provided by their official partner. This oil is formulated specifically for high-heat, high-shear racing conditions and is not available to the general public for standard street use.

Conclusion: Consistency Through Controlled Variation

So, to wrap this up, are all NASCAR engines the same? The clear answer is no, not exactly. While the foundation—the naturally aspirated 5.8L V8—provides a baseline level of consistency across the Cup Series fleet, the specific components, tuning nuances, and supporting systems (like oiling and cooling) are customized right up to the legal limit by each dedicated team. Furthermore, the engines in the Xfinity and Truck Series are intentionally dialed back to serve different competitive and fiscal goals.

This controlled complexity is what makes NASCAR technology so fascinating. It’s a brilliant balancing act: demanding massive, predictable power while ensuring that no single team gains an insurmountable advantage through engine superiority alone. As a fan, knowing this foundation helps you appreciate the incredible engineering prowess required every weekend, regardless of which NASCAR series you are tuning in to watch. You now have the knowledge to understand that beneath the paint schemes, powerful, purpose-built machines are battling it out, all shaped by the strict, proven power rules of the sport.